A kind of automatic assembly equipment for switching power supply pressure strip

A technology of automatic assembly and switching power supply, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of slow efficiency and achieve the effect of improving assembly efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are a part of the embodiments of the present invention, but not all of the embodiments.

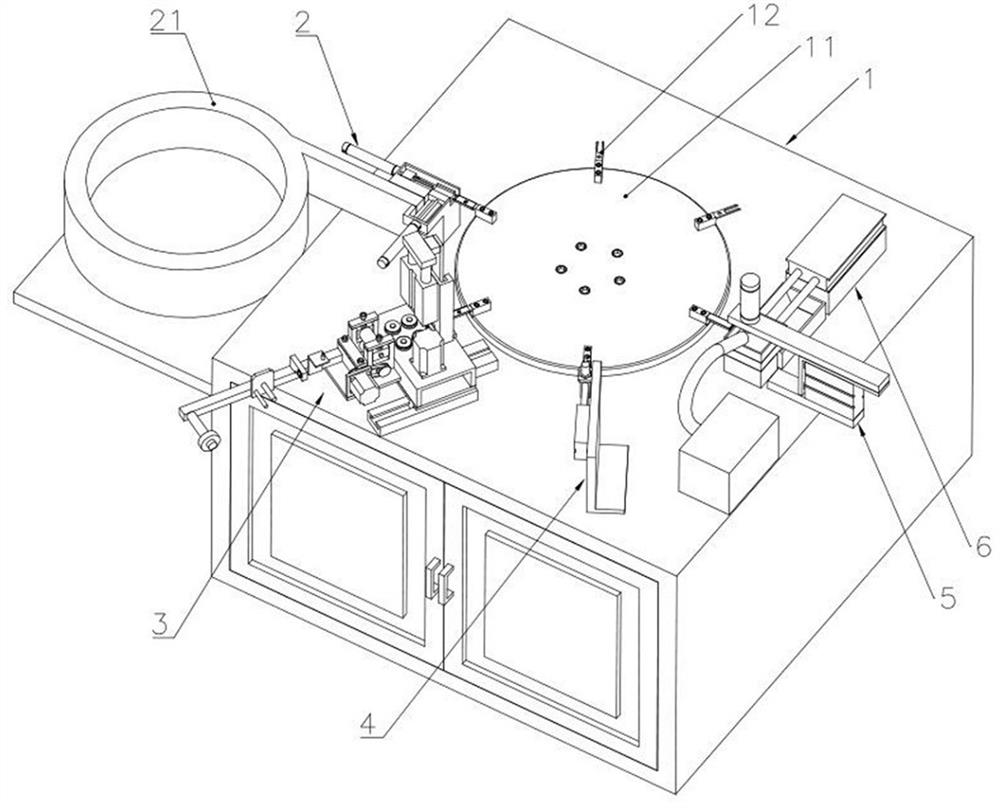

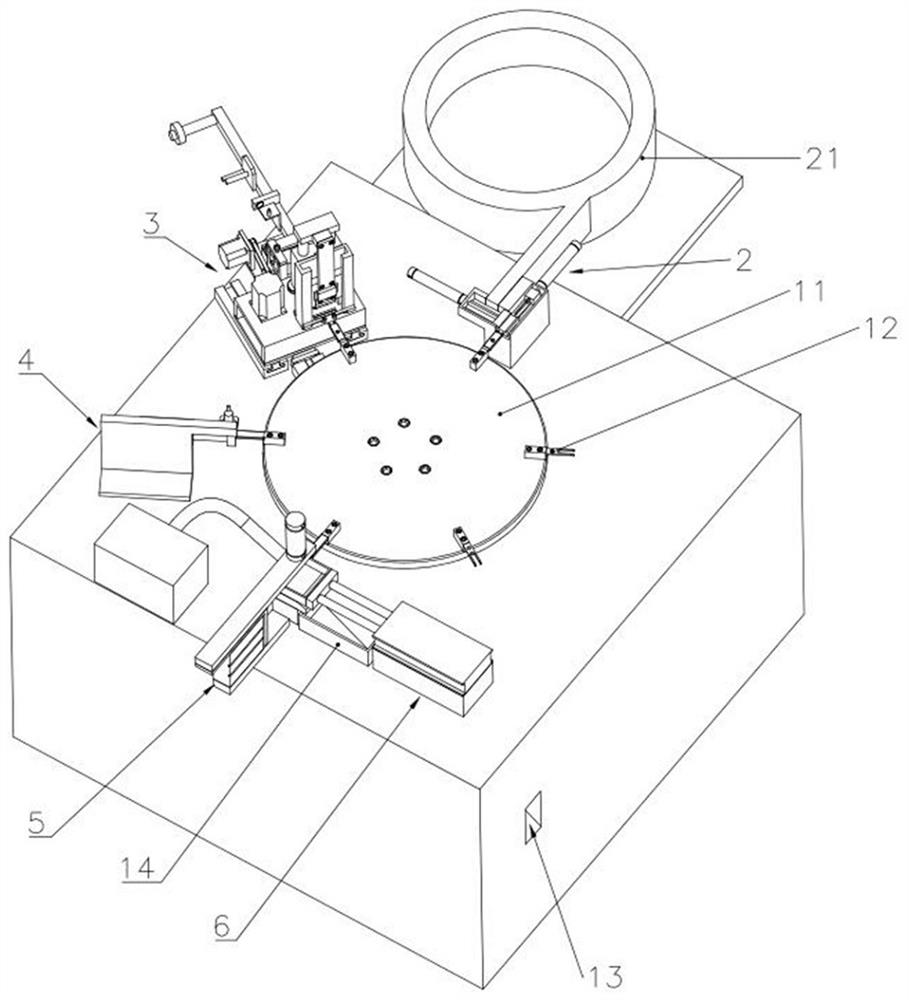

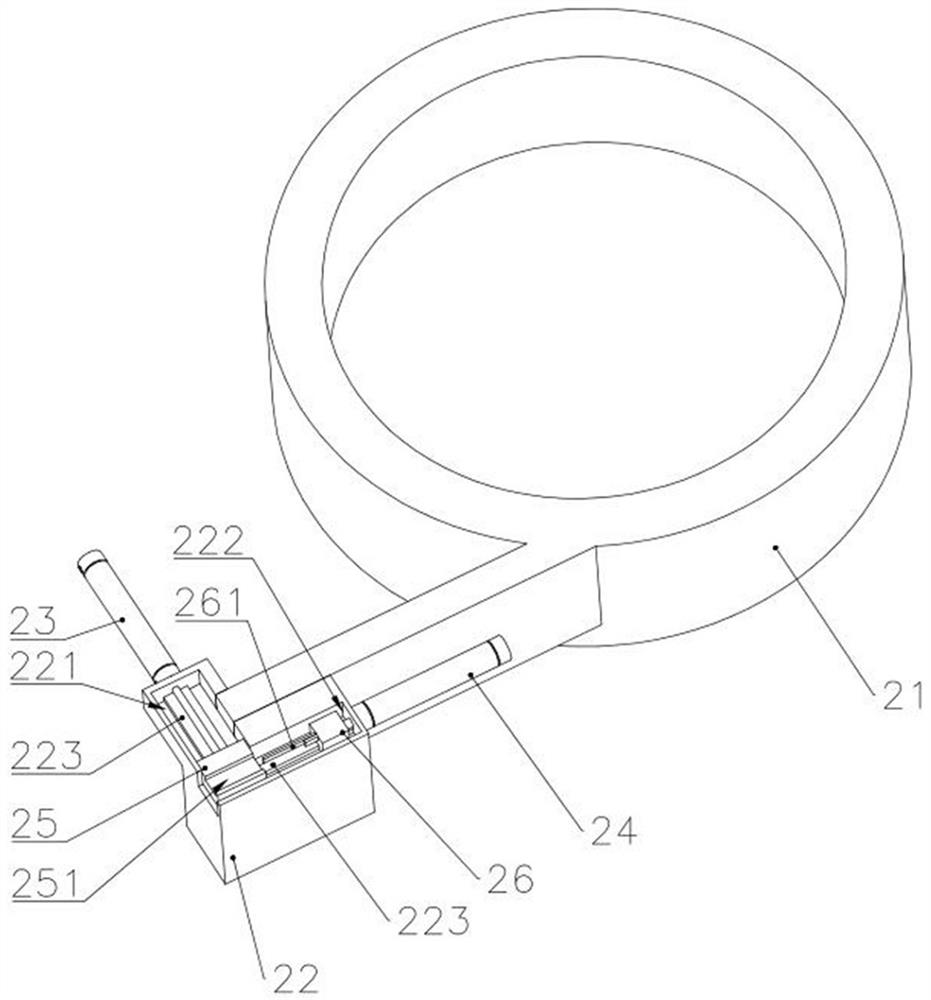

[0041] like Figure 1-9 As shown in the figure, an automatic assembling equipment for switching power supply layering includes: a processing table 1, on which is provided a turntable 11 and a stepping motor for driving the turntable 11 to perform step-by-step rotation, the turntable 11 is provided with several The carrier jig 12, the carrier jig 12 includes a connecting block 121 connected to the turntable 11 and a carrier bar 122 for carrying the bead; a bead loading device 2 for placing the bead on the carrier bar 122; heat shrinkable insulation The sleeve feeding device 3 is used to sleeve the heat-shrinkable insulating sleeve on one end of the bead, and the heat-shrinkable insulating sleeve feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com