Dispensing machine

A glue dispensing machine and glue dispensing mechanism technology, applied in the field of glue dispensing, can solve the problems of needle blockage, solidified colloid bonding inner wall is difficult to clean, etc., to achieve the effect of easy falling off, changing viscosity, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

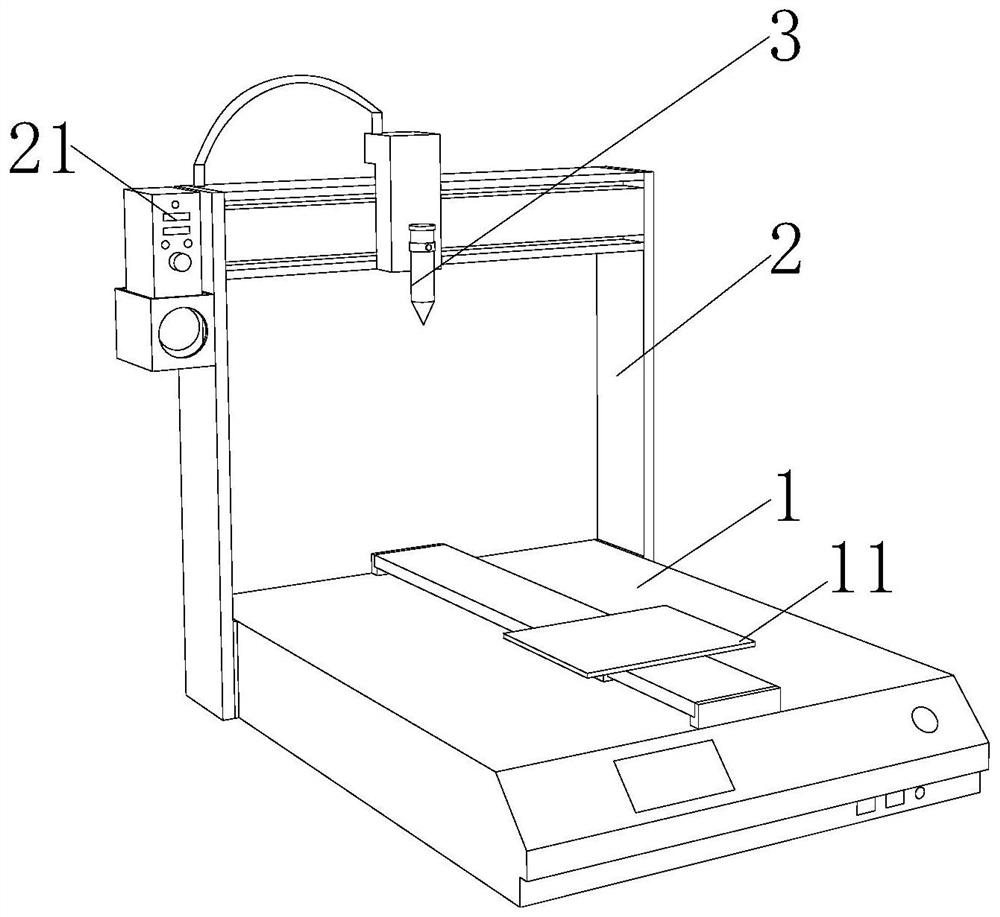

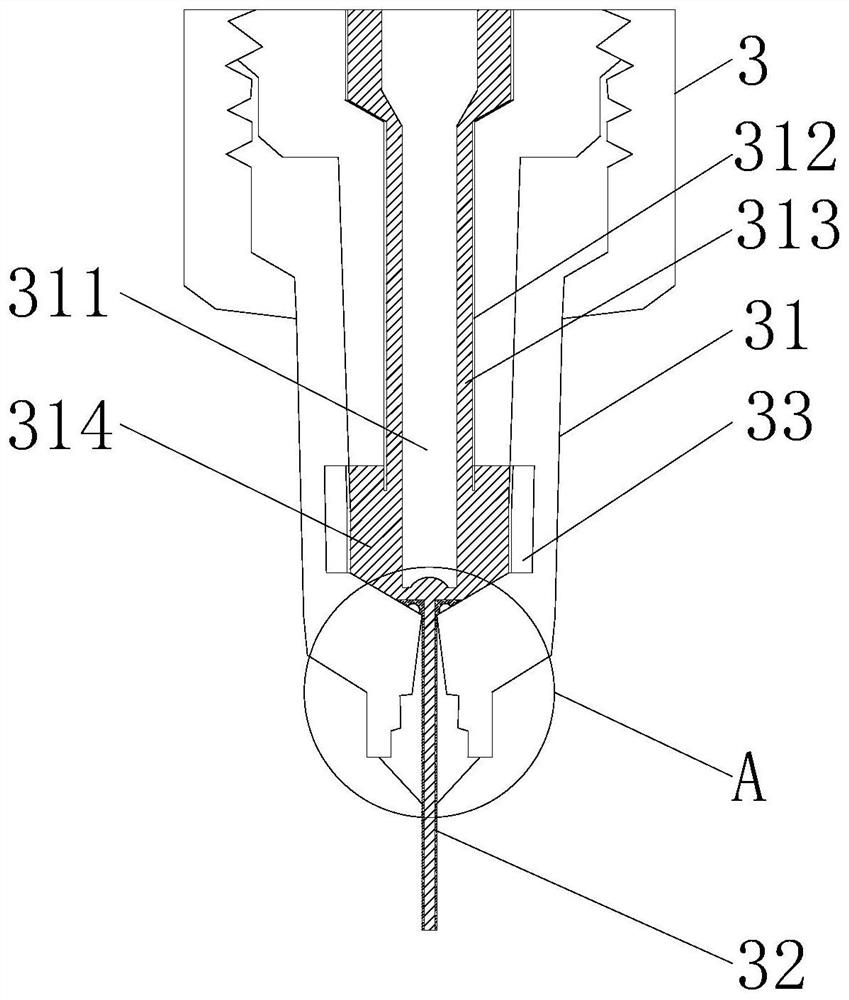

[0029] Such as Figure 1-Figure 9 As shown, the present invention provides a kind of dispensing machine, frame 1, support frame 2 and dispensing mechanism 3, in the present embodiment, frame 1 comprises movable bearing plate 11, and support frame 2 comprises air pressurizer 21 , the dispensing mechanism 3 includes a dispensing head 31 and a needle 32, the dispensing head 31 includes a spray needle 311, a colloid stop block 312 and a colloid chamber 313, the outer wall of the lower end of the spray needle 311 is provided with a screw thread 314, and the bottom of the spray needle 311 adopts The semicircular groove is set. When in use, place the substrate to be dispensed on the movable carrier plate 11, open the air pressurizer 21 to pressurize the colloid chamber 313, the glue liquid is filled in the colloid chamber 31, and the spray needle 311 is in the Under the action of the spring force, it moves downward, the spherical surface at the end of the spray needle 311 collides wi...

Embodiment 2

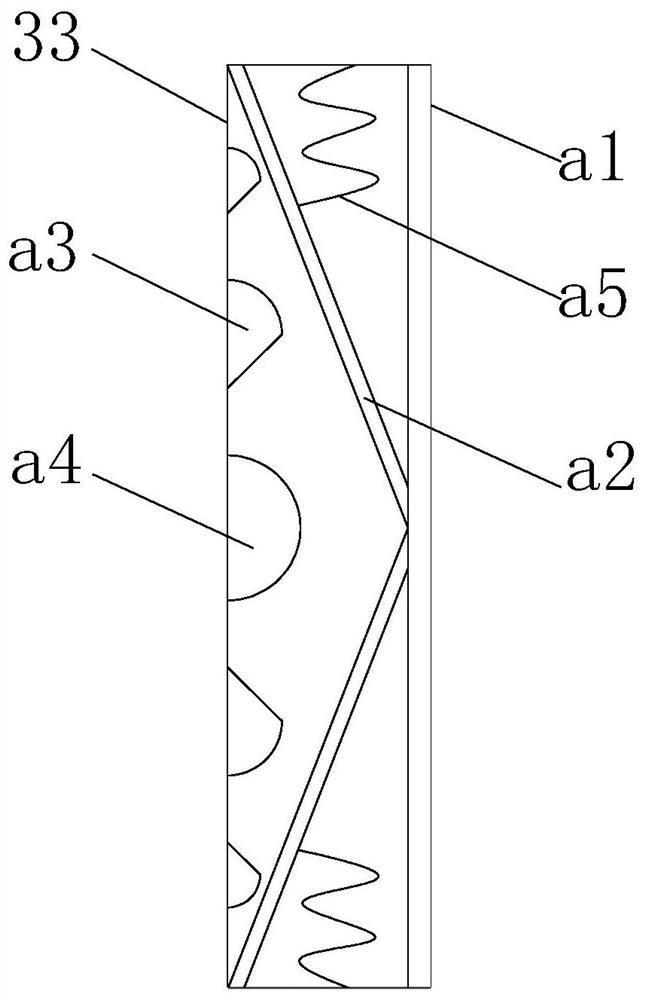

[0033] Such as Figure 7 As shown, on the basis of Example 1, the present invention provides a technical solution: a first partition b1 is provided inside the metal soft board a1, and the first partition b1 is arranged in multiple layers, and each layer of the first partition Each b1 is provided with an elastic ball b2 correspondingly, and the vibration of the elastic soft board a2 drives the elastic ball b2 inside the metal soft board a1 to collide in the cavity separated by the first partition b1.

Embodiment 3

[0035] Such as Figure 5As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, a second partition c3 is provided in the middle of the first barrier block a3, and the upper end of the second partition c3 is provided There is a ball c4, the outer wall of the center side of the first barrier block a3 is provided with an elastic block c1, and the inner wall of the elastic block c1 is fixedly connected with a second spring c2, and the elastic block c1 is set on an outer convex arc surface, and its collision resilience is greater. The outer wall on the other side of the center of the first barrier block a3 is set with an indented arc surface, wherein, when the elastic soft plate a2 is reset, one end of the elastic soft plate a2 and the outer wall on the other side of the center of the first barrier block a3 are indented. Contact, small barrier, easy reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com