Ceramic tile sealant production device

A production device and technology of beautifying agent, which is applied in the field of ceramic tile beautifying agent production devices, can solve the problems of single action direction, single operation method, and unsatisfactory mixing effect, etc., and achieve the goal of increasing surface area, improving effect, and good moving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

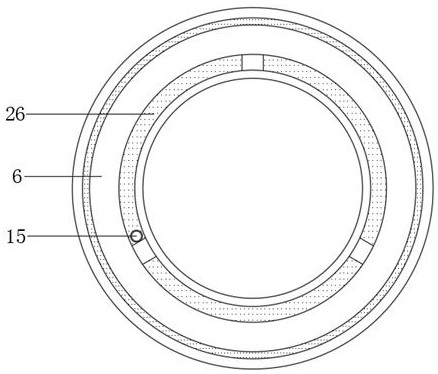

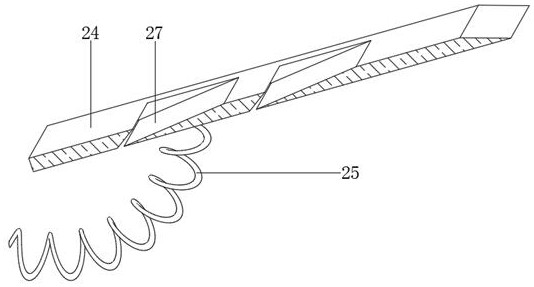

[0029] refer to Figure 1-4 , a ceramic tile beautifying agent production device, including a mixing tank 1, a water bath outer cylinder 17 is welded on the outer wall of one end of the mixing tank 1, and the four corners of the top outer wall of the water bath outer cylinder 17 are fixed with hydraulic rods 7 by bolts, and the hydraulic rod 7 The end of the extension rod is fixed with the same lifting top plate 12 by bolts, the outer wall of the bottom of the lifting top plate 12 is welded with a fixed cylinder 8, and the inner wall of the fixed cylinder 8 near the bottom is connected with a distance-increasing ring disc 28 through a bearing rotation, and the distance-increasing ring disc 28 Both sides of the outer wall of the bottom of the bottom are welded with staggered arc rods 11, and the bottom ends of the arc rods 11 are welded with side flaps 20, and the bottom ends of the side flaps 20 are welded with the same bottom end plate 21. The center of the outer wall of the ...

Embodiment 2

[0039] refer to Figure 5 , a ceramic tile beautifying agent production device, compared with Embodiment 1, this embodiment also includes that the inner side of the C-shaped bottom plate 22 is welded with support pieces 31 distributed equidistantly; using the support pieces 31 arranged on the C-shaped bottom plate 22, increasing The bottom end plate 21 has a stirring effect.

[0040] In the present invention, the corners of the side flaps 20 are provided with diagonal holes 30; through the diagonal holes 30 arranged on the side flaps 20, part of the material can be placed near the diagonal holes 30 during the rotation of the side flaps 20. Produces a relative convective effect.

[0041] When the present invention is used: use the supporting piece 31 arranged on the C-shaped bottom plate 22 to increase the stirring effect of the bottom end plate 21; through the diagonal hole 30 arranged on the side folding plate 20, during the rotation of the side folding plate 20, part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com