Assembling device for producing semiconductor light-emitting element

A technology for light-emitting components and assembling devices, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inability to assemble semiconductors uniformly, low work efficiency, etc., to prevent bending, improve work efficiency, and prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

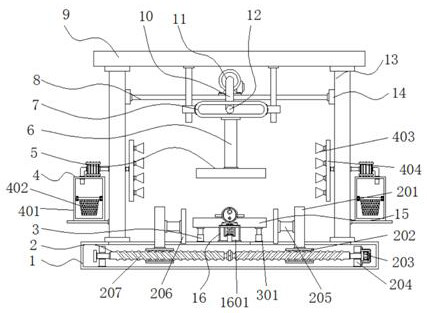

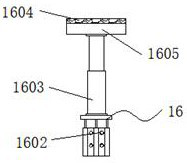

[0035] Example 1: See Figure 1-6, an assembly device for the production of semiconductor light-emitting elements, comprising a base plate 1 and a support plate 13, the two sides of the top of the base plate 1 are fixedly connected with support plates 13, the top of the support plate 13 is provided with a top plate 9, and one side of the support plate 13 is provided with The dust removal mechanism 4, the inside of the bottom plate 1 is provided with a limit mechanism 2, the top of the bottom plate 1 is provided with a workbench 15, a buffer structure 3 is provided between the bottom plate 1 and the workbench 15, and the top of the workbench 15 is provided with a pressure plate 5, the workbench Limiting grooves 17 are arranged on both sides of the inside of 15, a feeding mechanism 16 is arranged at one end of the top of the bottom plate 1, and a uniform-speed lifting mechanism is arranged at the bottom of the top plate 9;

[0036] see Figure 1-6 , an assembly device for the p...

Embodiment 2

[0039] Embodiment 2: The limit mechanism 2 is composed of a connecting column 201, a moving sleeve 202, a servo motor 203, a support rod 204, a connecting block 205, a limit rod 206 and a screw shaft 207. The screw shaft 207 is arranged inside the bottom plate 1, and the screw The outside of the shaft 207 is provided with a moving sleeve 202, the top of the moving sleeve 202 is fixedly connected with a connecting column 201, one side of the connecting column 201 is fixedly connected with a connecting block 205, and one side of the connecting block 205 is fixedly connected with a limit rod 206, a support rod 204 is fixedly connected to both sides of the inner bottom of the bottom plate 1, and one side of the support rod 204 is provided with a servo motor 203, and the model of the servo motor 203 is 80HB-02430;

[0040] The threads on both sides of the screw shaft 207 are opposite, and the servo motor 203 is fixedly connected to the screw shaft 207 through a coupling;

[0041] S...

Embodiment 3

[0042] Embodiment 3: The buffer structure 3 is composed of a sleeve 301, a sleeve rod 302, a spring groove 303, a buffer spring 304 and a support column 305. The sleeve 301 is fixedly connected to the top of the bottom plate 1, and the sleeve rod 302 is fixedly connected to the bottom of the workbench 15. At the four corners of the end, one side of the sleeve rod 302 is provided with a spring groove 303, and the inside of the spring groove 303 is provided with a buffer spring 304. 15 both ends of the bottom;

[0043] The sleeve 301 is socketed on the bottom end of the sleeve rod 302, and the sleeve rod 302 is symmetrically distributed with respect to the vertical center line of the workbench 15;

[0044] Specifically, such as figure 1 and Figure 6 As shown, when the pressing plate 5 assembles the semiconductor on the top of the workbench 15, the pressing plate 5 needs to squeeze the semiconductor. When the pressing plate 5 squeezes the semiconductor, the workbench 15 will s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com