Reliability prediction method under maintenance support of manned spacecraft

A manned spacecraft, reliability technology, applied in the direction of instrumentation, design optimization/simulation, special data processing applications, etc., can solve problems such as availability allocation difficulties, complex calculations, increased work difficulty, etc., to achieve good engineering implementability , easy to decompose, and the overall simple effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to more clearly describe the embodiments of the present invention or the technical solutions in the prior art, the following will briefly introduce the drawings that are used in the embodiments. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can also obtain other drawings according to these drawings without creative efforts.

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the embodiments of the present invention are not therefore limited to the following embodiments.

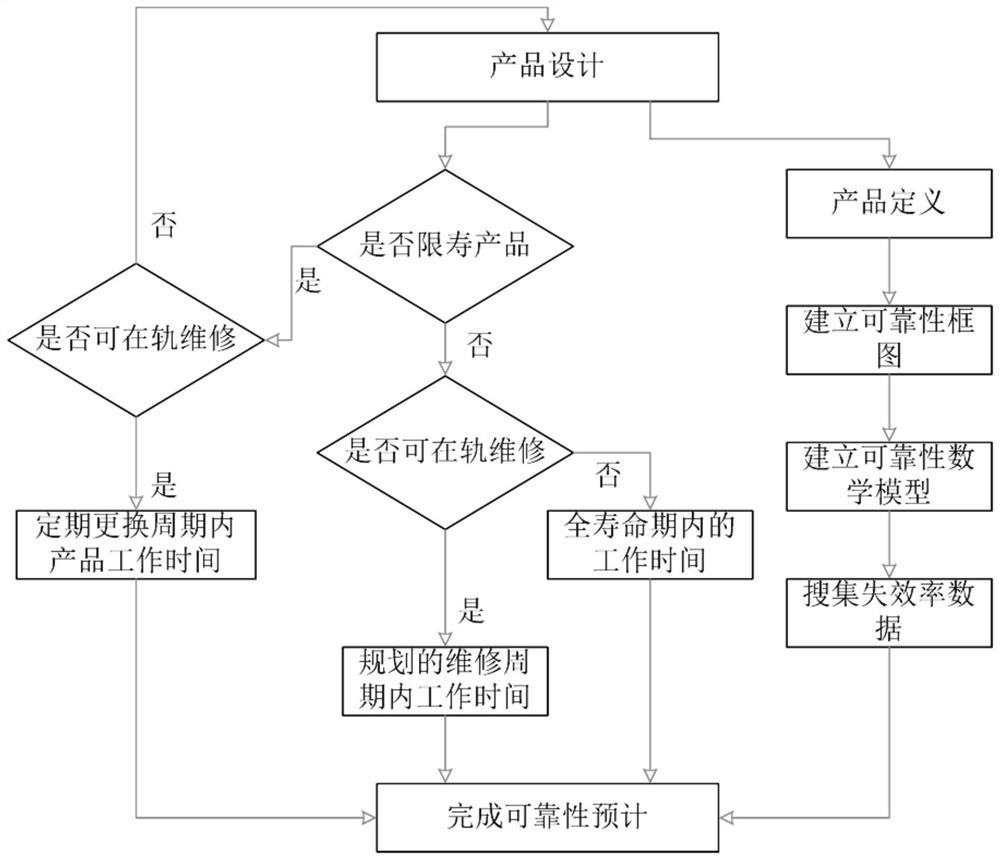

[0039] see figure 1 , the reliability prediction method under the support of manned spacecraft maintenance of the present invention, firstly carry out the scheme design to the manned spacecraft components. Specifically, component scheme design is carried out acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com