Novel intelligent granary system

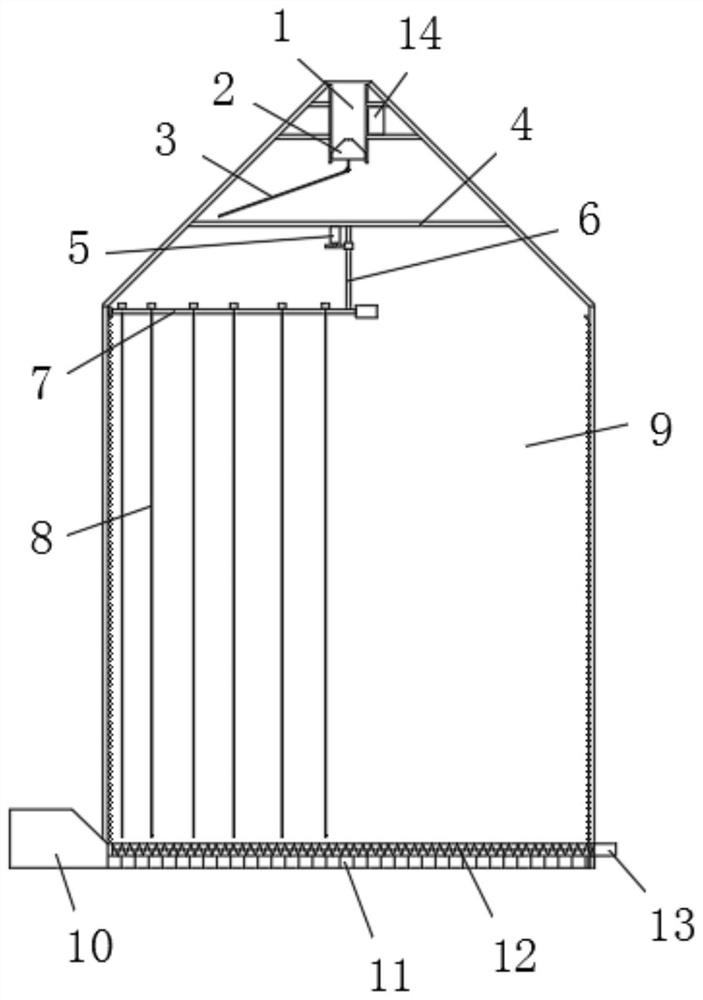

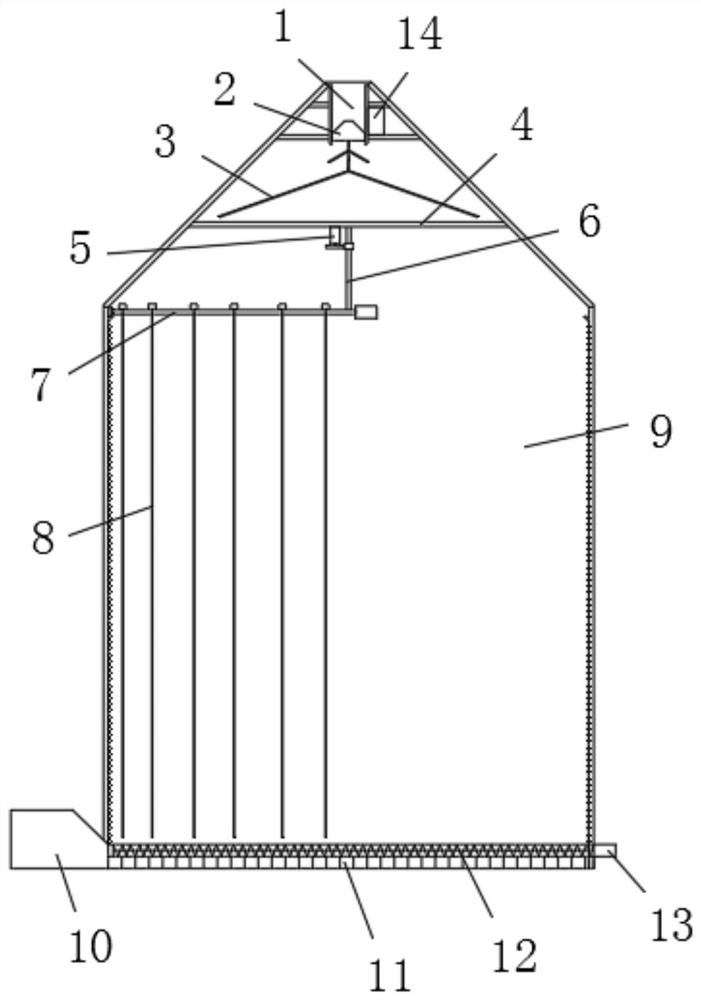

A granary, a new type of technology, applied in the field of grain drying in the granary, can solve the problems that the flowing air cannot enter the drying in a comprehensive and uniform manner, reduce the speed and efficiency of grain drying, and achieve faster drying rate and drying comprehensiveness. Ensuring uniform and comprehensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

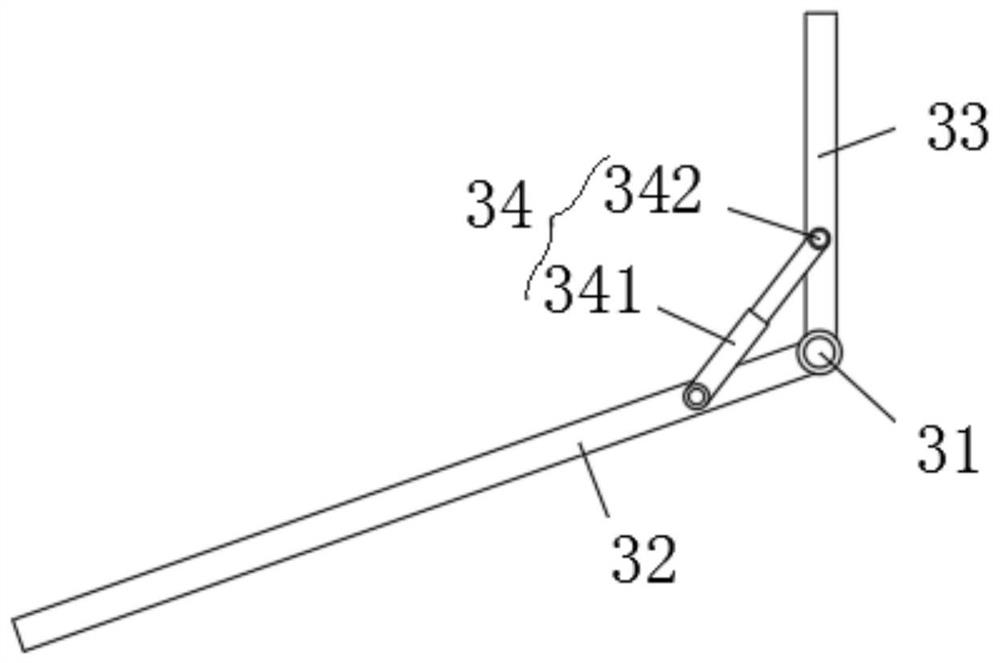

[0055] like image 3As shown, the spreading mechanism 3 includes a first connecting rod 33 connected with the unpowered rotor 2, the bottom of the first connecting rod 33 is rotationally connected with the spreading plate 32 through the rotating shaft 31, and the first connecting rod 33 is provided with an adjusting spreading plate 32 The pitching and rotating adjustment assembly 34, the first connecting rod 33 rotates under the drive of the unpowered rotor 2, which can drive the spreading plate 32 to move circularly, and cooperate with the pitching adjustment function of the adjusting assembly 34 to spread the grain in a single-channel pitching ring , to ensure the uniformity of grain spreading.

[0056] The number of spreading plates 32 can be multiple, and with the silo of the granary 9 as the center of the circle, they are set at certain angles according to the diameter of the granary 9, so that when the unpowered rotor 2 fails, the uniformity of spreading into the silo ca...

Embodiment 2

[0059] like Figure 4 As shown, the distributing mechanism 3 includes a second connecting rod 35 connected to the unpowered rotor 2, the second connecting rod 35 is provided with a downward-inclined flow guide and leveling plate 36, and the bottom of the second connecting rod 35 is provided with several A downward-inclined spreading chute 37, and a number of spreading holes 38 are arranged in the spreading chute 37, and the second connecting rod 35 rotates under the drive of the unpowered rotor 2, and the falling grains will first contact the diversion flow at this moment. The leveling plate 36 is preliminarily evenly divided, and then the grain will be evenly distributed in a circular state along several spreading slides 37, and spread from the spreading hole 38, so that the effect of multi-channel and multi-point circular spreading of the grain can be realized.

[0060] like Figure 5 As shown, the rotary drive assembly 5 is also included, the rotary drive assembly 5 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com