Active shaft type combined air bearing

An air bearing and active technology, applied in the direction of rotating combined bearings, shaft and bearings, sliding contact bearings, etc., can solve the problems of easy damage of foil bearings and reduce the actual relative speed of the rotating shaft, so as to reduce wear loss and increase relative speed , Reduce relative friction and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

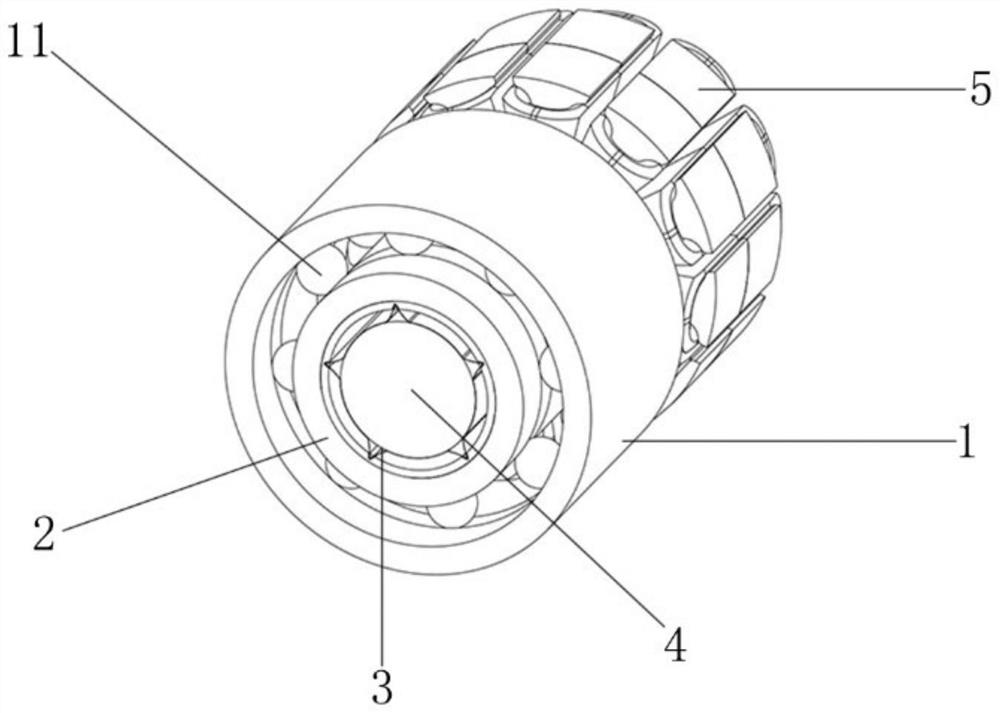

[0024] Such as figure 1 Shown: an active shaft-type combined air bearing, including an outer bearing seat 1, an inner bearing seat 2, a roller shaft 4 and several balls 11, each ball is located between the outer bearing seat and the outer ball bearing seat 21, and the inner air shaft A foil ring 3 is provided on the inner wall of the seat 22 , and the roller 4 is inside the foil ring 3 .

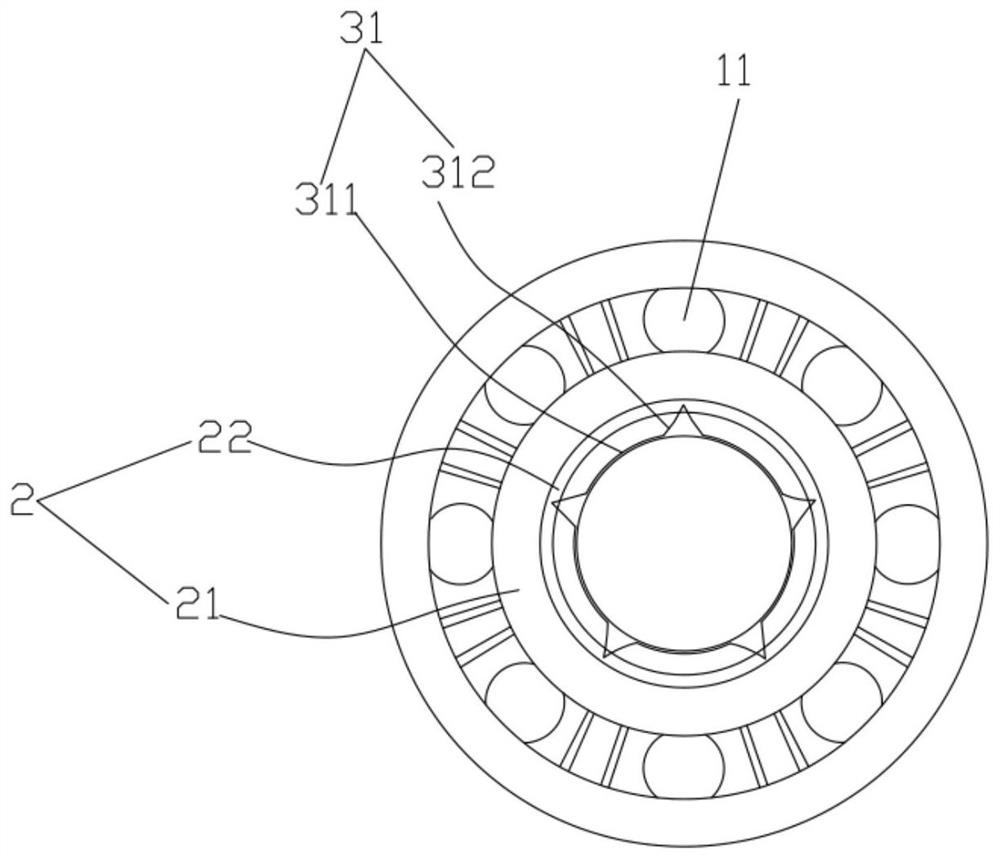

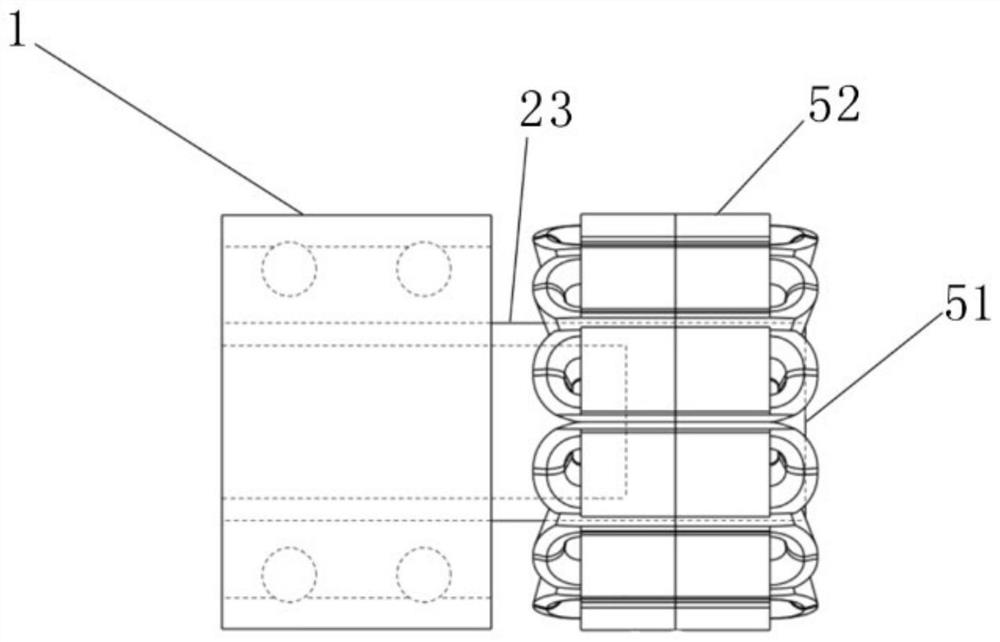

[0025] Such as figure 2 As shown: the inner bearing seat 2 includes an outer ball shaft seat 21, an inner air shaft seat 22 and an extended coaxial seat 23, and the outer ball shaft seat 21, the inner air shaft seat 22 and the extended coaxial seat 23 are integrally formed. The foil ring 3 is composed of five independent rigid foils 31 connected end to end in sequence, and the independent rigid foils 31 include arc-shaped rigid bearing parts 311 and elastically deformable pin parts 312 . The independent rigid foil has a good deformation space after being excited by the outside. The shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com