Garbage water vapor catalytic gasification device capable of recording data and using method

A technology of data recording and water vapor, which is applied to the feeding tool of gasification device, gasification process, and the manufacture of combustible gas, etc., can solve the problem of inability to accurately control the feeding position, uneven heating of garbage in the gasifier, and affect the gasification effect. and other problems, to avoid untimely feeding, improve the effect, and improve the sealing environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

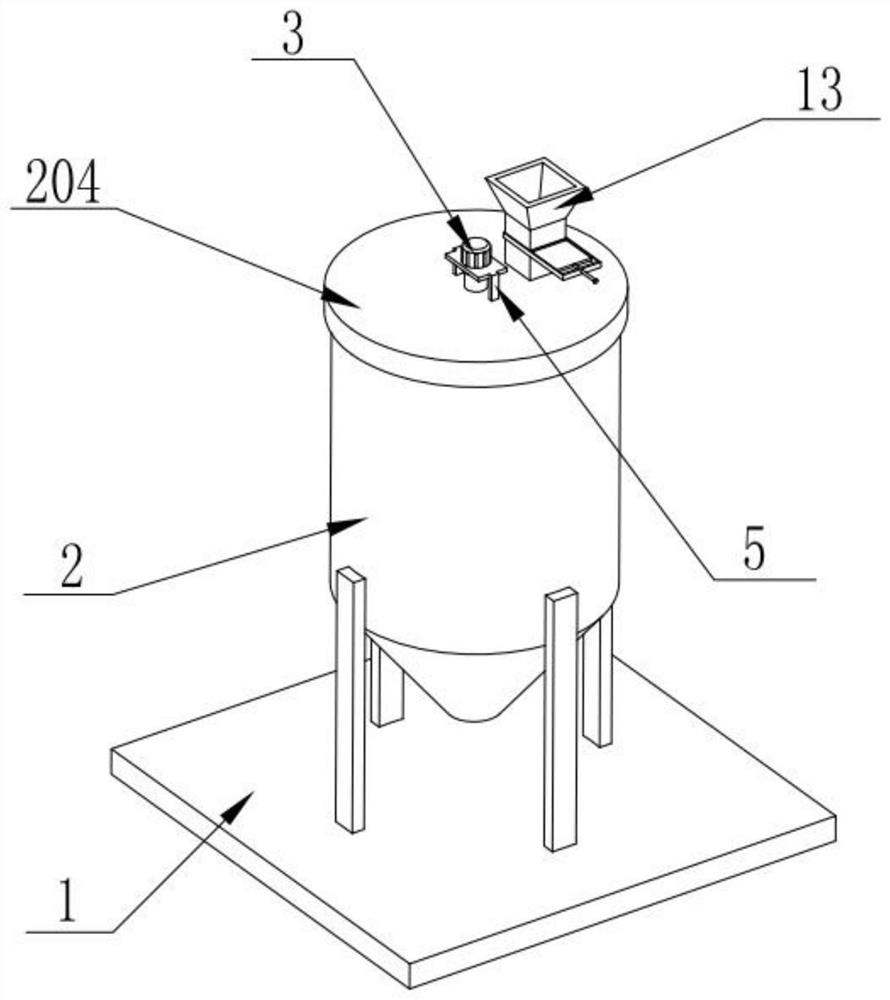

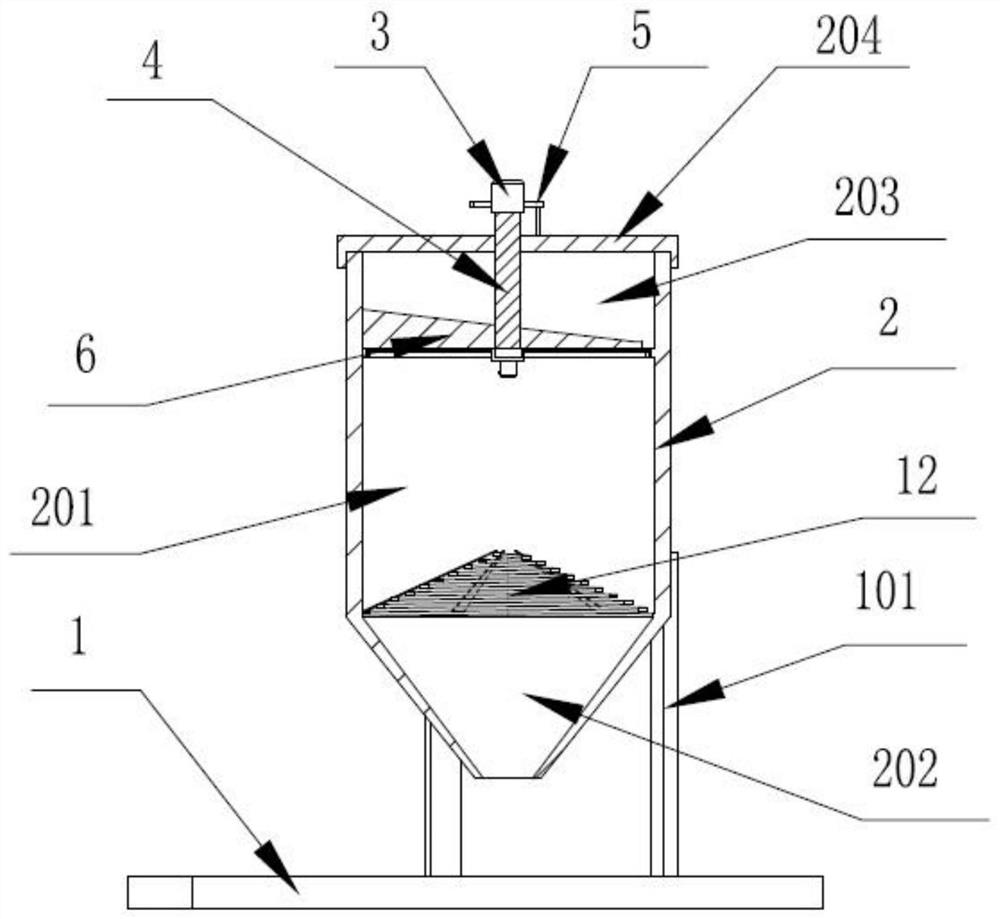

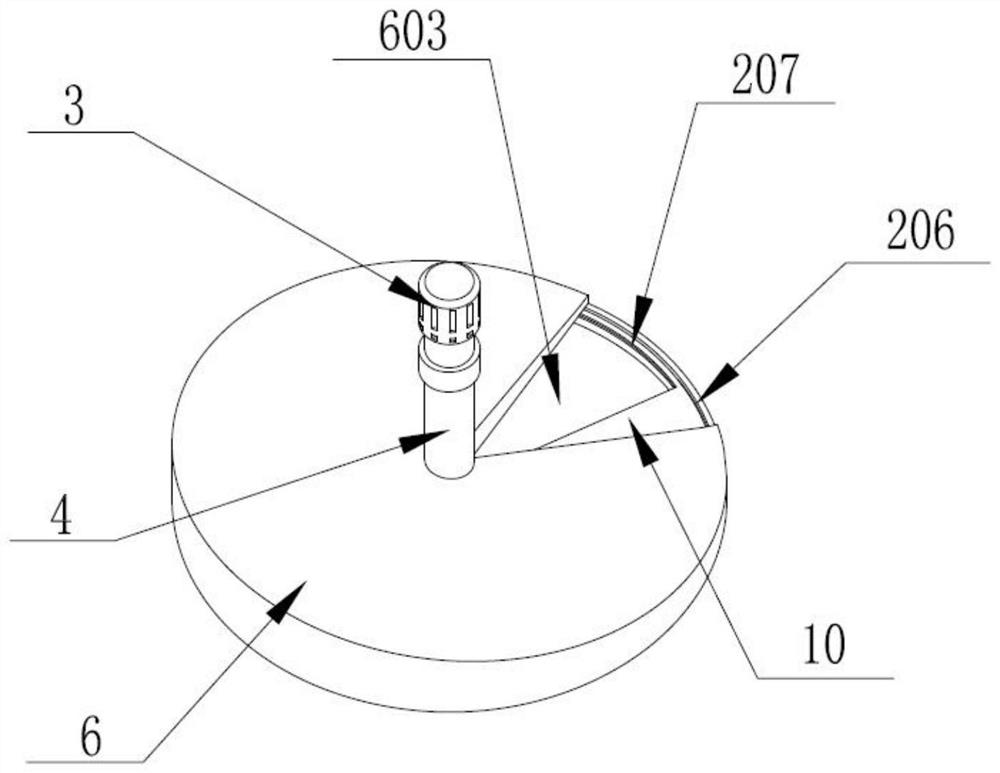

[0028] Such as Figure 1 to Figure 8 As shown, a data-recordable garbage steam catalytic gasification device includes a base 1, and a gasifier 2 is fixedly installed above the base 1 through a frame 101. The gasifier 2 is set as a hollow barrel structure, and A furnace cover 204 is sealed above the gasification furnace 2, and a pre-feed chamber 203, a gasification chamber 201, and a slag discharge chamber 202 are sequentially arranged in the hollow cavity of the gasification furnace 2 from top to bottom. A fire grate 12 is fixedly arranged between the slag chambers 202, and the fire grate 12 is fixedly connected to the inner wall of the gasification furnace 2 through the fire grate 12, so that the garbage in the gasification chamber 201 can complete the gasification process under the action of the fire grate 12 At the same time, the generated residue is discharged into the slagging chamber 202 , and is discharged out of the gasifier 2 through the bottom outlet of the slag disc...

Embodiment 2

[0039] The method for using the data-recordable garbage water vapor catalytic gasification device in this embodiment 2 includes a sensor, a control room, a first motor and a second motor, the first motor is used to control the rotation of the turntable, and the second motor is used to control the rotation of the turntable. The rotation of the plate, the sensor, the first motor and the second motor are electrically connected to the control room respectively, and the preset temperature is preset in the control room, and the temperature value detected by the surface of the garbage is obtained by the sensor and compared with the preset temperature, and compared The results are transmitted to the control room.

[0040] The method of using the data-recordable garbage water vapor catalytic gasification device of the present embodiment 2 first starts the first motor 3, and the turntable 6 is driven by the first motor 3 to rotate around the axis of the gasifier 2 on the boss 205. Due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com