Preparation process of novel water-based nano thermal insulation material

A technology of thermal insulation and preparation technology, which is applied in the direction of climate sustainability, solid waste management, sustainable waste treatment, etc., and can solve problems such as poor thermal conductivity, poor thermal insulation performance, and water failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

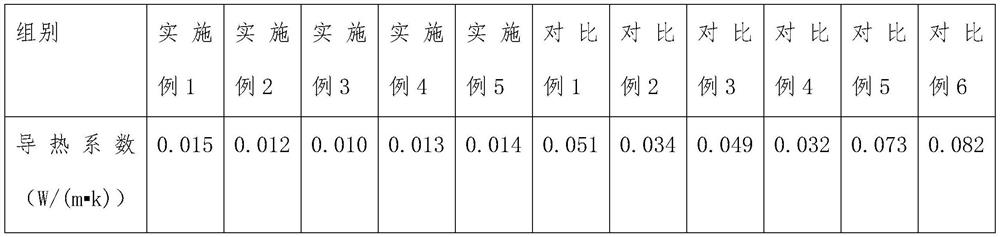

Examples

Embodiment 1

[0027] Firstly prepare the following raw materials according to parts by weight: 40 parts of porous water-based nano silica suspension, 2 parts of nano titanium dioxide, 10 parts of modified attapulgite, 1 part of wetting agent, 6 parts of modified fly ash, thickener 2 parts, 10 parts of modified rubber ridge stone, 4 parts of inorganic fiber, 12 parts of modified expanded perlite, 3 parts of flame retardant, 1 part of defoamer, 6 parts of vitrified microbeads, 2 parts of ethylene-vinyl acetate copolymer part, 20 parts of deionized water; then modified attapulgite, modified fly ash, modified jelly stone, inorganic fiber, modified expanded perlite are fully ground, then sieved to obtain mixture A; then Nano-titanium dioxide, ethylene-vinyl acetate copolymer and deionized water are put into a sealed mean emulsifier for high-speed shearing and grinding to obtain a premixed slurry, and vitrified microbeads are added to the premixed slurry, and the mixture is continuously stirred to...

Embodiment 2

[0039] First prepare the following raw materials according to parts by weight: 43 parts of porous water-based nano-silica suspension, 3 parts of nano-titanium dioxide, 12 parts of modified attapulgite, 2 parts of wetting agent, 7 parts of modified fly ash, thickener 2.5 parts, 12 parts of modified rubber ridge stone, 5 parts of inorganic fiber, 13 parts of modified expanded perlite, 4 parts of flame retardant, 1.5 parts of defoamer, 7 parts of vitrified microbeads, 3 parts of ethylene-vinyl acetate copolymer part, 22 parts of deionized water; then modified attapulgite, modified fly ash, modified jelly stone, inorganic fiber, modified expanded perlite are fully ground, then sieved to obtain mixture A; then Nano-titanium dioxide, ethylene-vinyl acetate copolymer and deionized water are put into a sealed mean emulsifier for high-speed shearing and grinding to obtain a premixed slurry, and vitrified microbeads are added to the premixed slurry, and the mixture is continuously stirre...

Embodiment 3

[0051] Firstly prepare the following raw materials according to parts by weight: 45 parts of porous aqueous nano silica suspension, 4 parts of nano titanium dioxide, 15 parts of modified attapulgite, 3 parts of wetting agent, 8 parts of modified fly ash, thickener 3 parts, 13 parts of modified rubber ridge stone, 6 parts of inorganic fiber, 14 parts of modified expanded perlite, 5 parts of flame retardant, 2 parts of defoamer, 8 parts of vitrified microbeads, 4 parts of ethylene-vinyl acetate copolymer part, 25 parts of deionized water; then modified attapulgite, modified fly ash, modified jelly stone, inorganic fiber, modified expanded perlite are fully ground, then sieved to obtain mixture A; then Nano-titanium dioxide, ethylene-vinyl acetate copolymer and deionized water are put into a sealed mean emulsifier for high-speed shearing and grinding to obtain a premixed slurry, and vitrified microbeads are added to the premixed slurry, and the mixture is continuously stirred to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com