A film laminating process for carton printing

A carton printing and carton technology, which is applied in the field of carton printing lamination process, can solve the problems affecting the quality of lamination and the aesthetics of carton surface, etc., and achieve the effect of improving the quality of lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

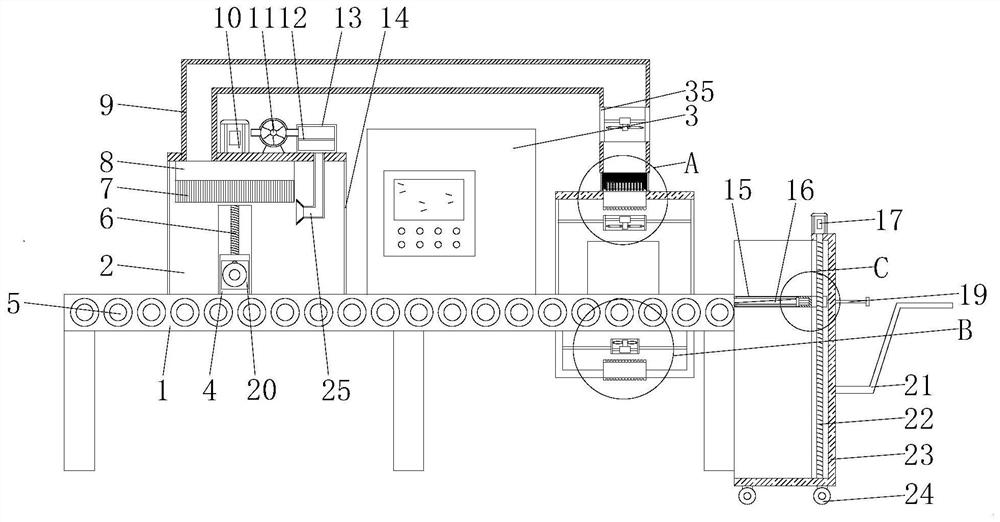

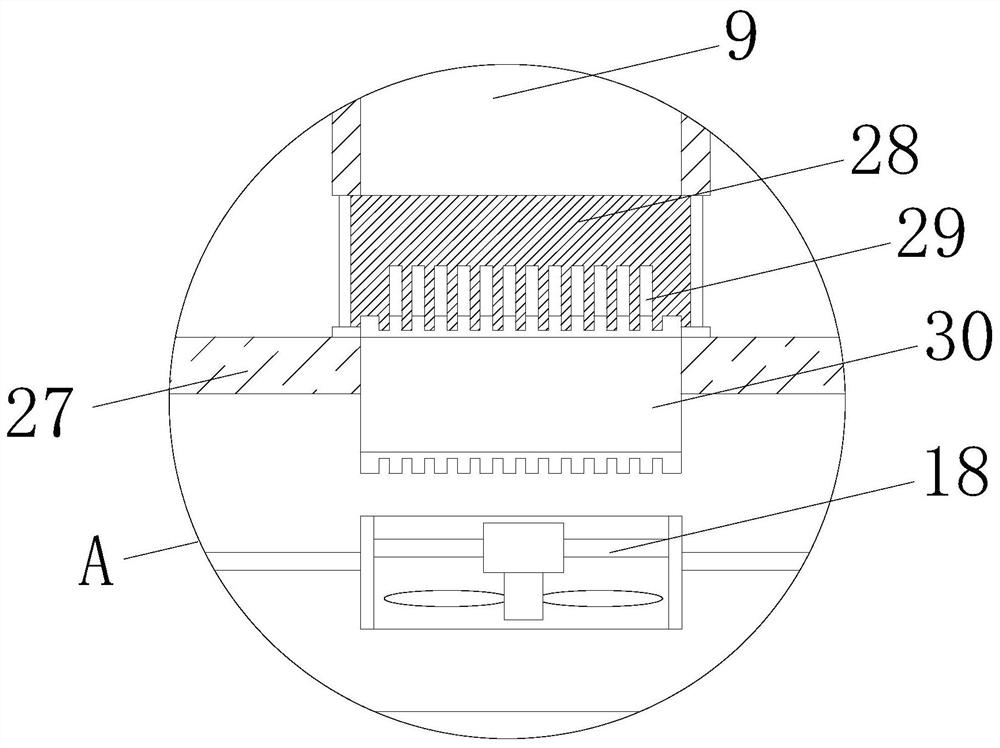

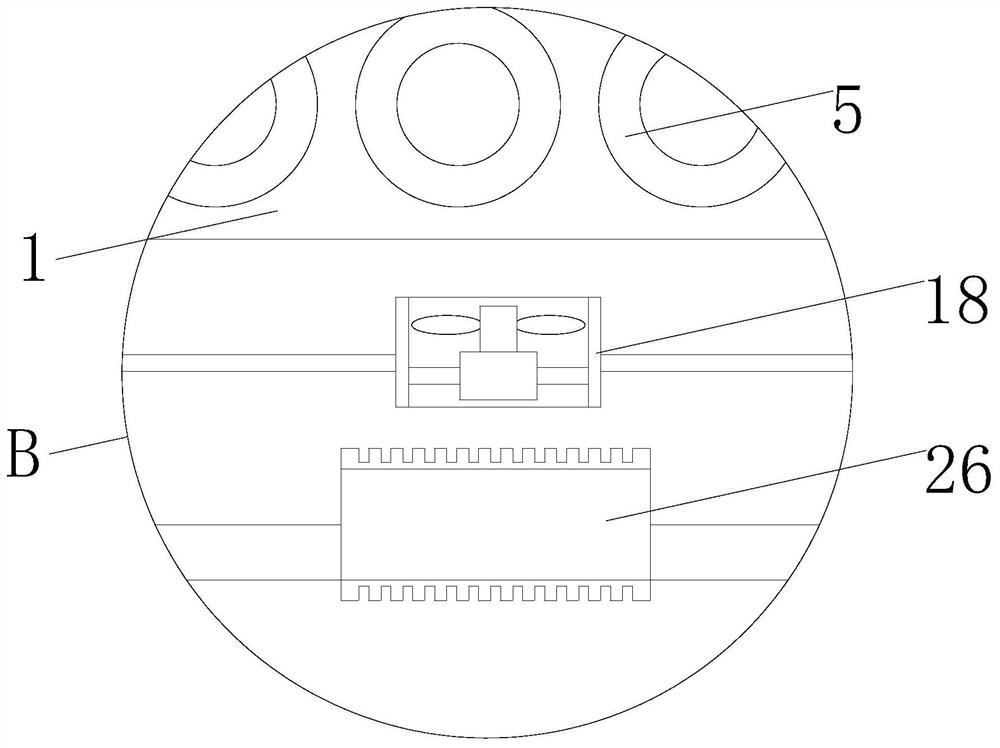

[0026] see Figure 1 to Figure 6, the present invention provides a technical solution: a film coating process for carton printing, including a frame body 1 and a film coating mechanism 3. One side of the frame body 1 is fixedly connected with a cleaning box 2, the other side of the frame body 1 is provided with a cooling box 27, one end of the frame body 1 is provided with a collection box 23, and both sides of the cavity of the cleaning box 2 are rotatably connected with a first The transmission screw 6, the surface of the first transmission screw 6 is threadedly fitted with the installation box 4, the inner cavity of the installation box 4 is fixedly installed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com