Improved cascade refrigeration method for liquefied natural gas

A refrigerant and refrigerant-level technology, applied in the field of pressurized liquid natural gas production, can solve the problems of large investment and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Material and energy balance simulations were carried out to illustrate the scenario shown in the figure and the results are presented in the table below.

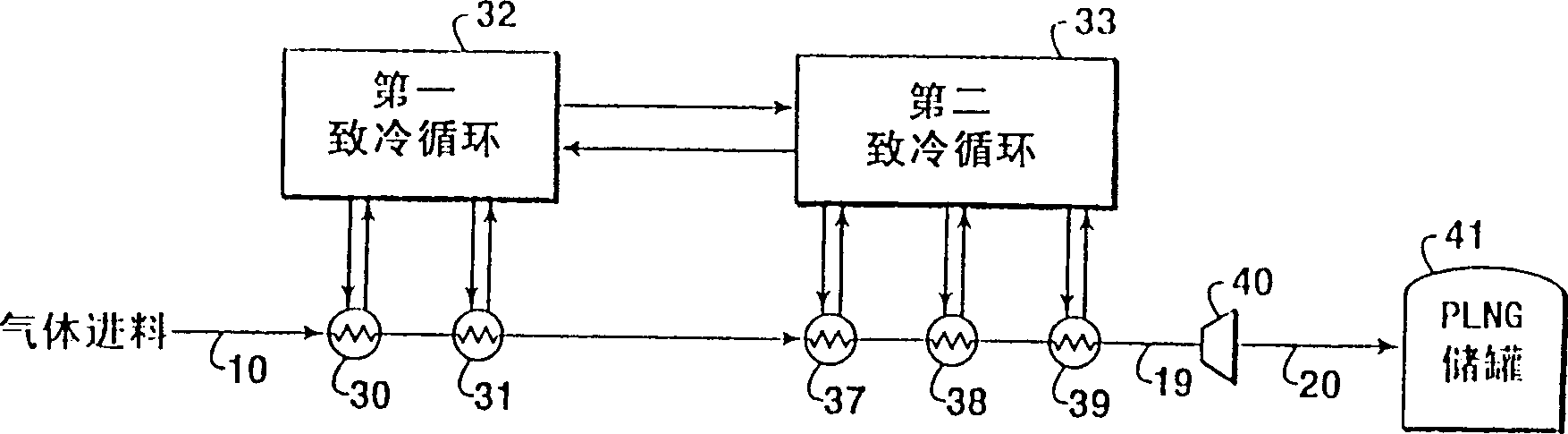

[0040] Data were obtained using the commercially available process simulator HYSYS TM data obtained, however, can also be obtained using other commercially available process simulation programs, including HYSIM TM 、PROII TM and ASPENPLUS TM , are familiar to those skilled in the art. The data in Table 1 are used to better understand figure 1 shown, but the invention is not unnecessarily limited thereto. Temperature and flow rates should not be considered limiting of the invention. Many variations are possible from the techniques disclosed here. In this arrangement, the first refrigeration cycle 32 is a propane system and the second refrigeration cycle 33 is an ethylene system.

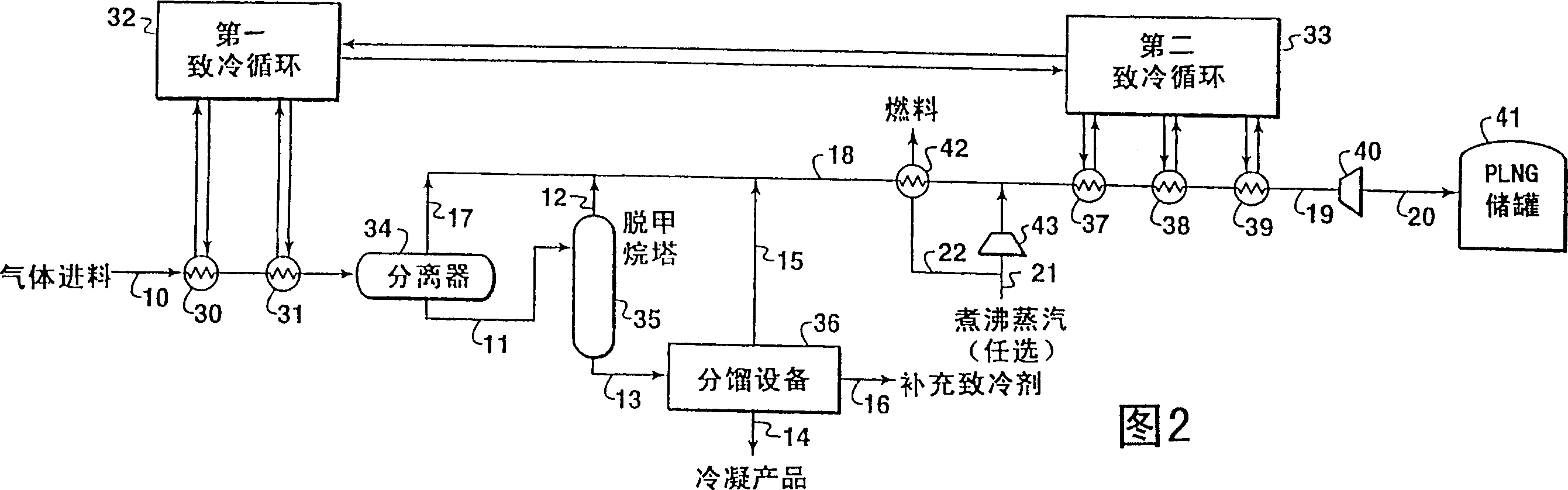

[0041] The data in Table 2 are used to better understand the scheme shown in Figure 2. In this arrangement, the first refrigeration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com