Dismounting and mounting oil pressurizing technology for nuclear power station shaft seal main pump motor flywheel

A nuclear power plant and flywheel technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of flywheel axial displacement, affecting flywheel installation interference and position accuracy, etc., to ensure installation accuracy, increase the degree of visualization, Effects of Resolving Stress Residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

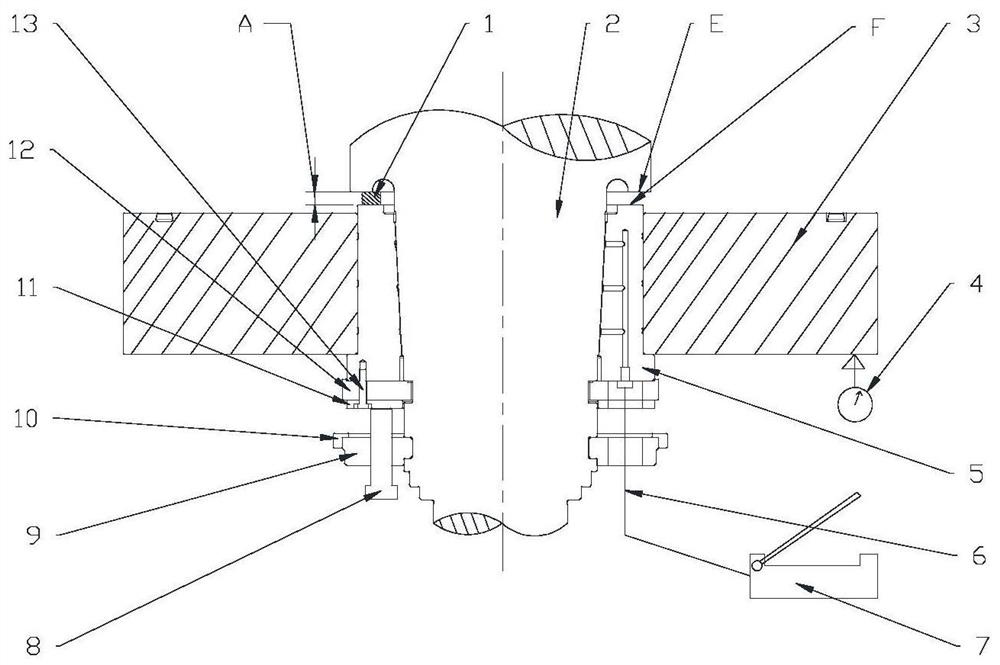

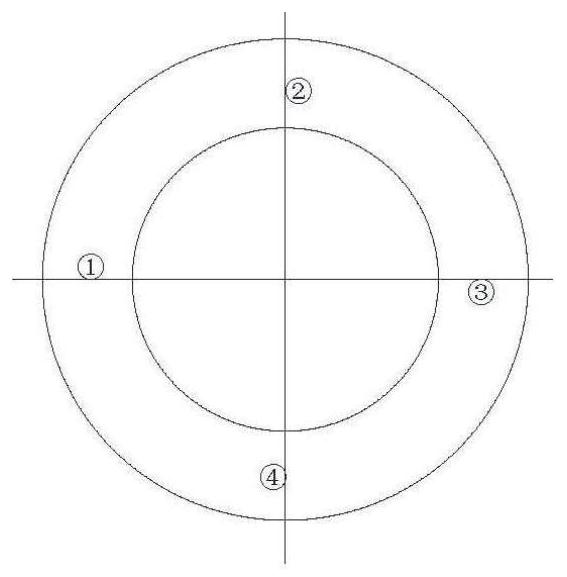

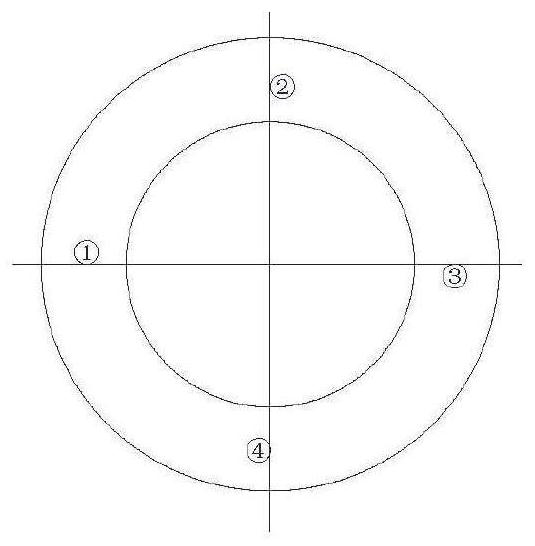

[0024] A nuclear power plant shaft seal main pump motor flywheel disassembly and assembly process for oil pressure, comprising the following steps: figure 1 As shown, 1) Hang the shaft 2 vertically into the inner hole of the flywheel inner sleeve 5 at room temperature, and drop it gently until the outer diameter of the shaft 2 contacts the inner hole of the flywheel 3 without any gap, and measure the flywheel inner sleeve 5 with a gauge block The distance between the F surface of the axis 2 and the E surface of the axis 2 is recorded as the A value, and the A value is measured by dividing the circumference into four points, which are respectively recorded as A 1 、A 2 、A 3 、A 4 , the measurement points such as figure 2 , image 3 As shown, according to the A value and the interference ⊿ value required by the design after the flywheel inner sleeve 5 and the shaft 2 are shrunk, calculate and determine the distance between the F surface of the flywheel inner sleeve 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com