Urban sewer pipeline anti-corrosion process method

A process method and pipeline technology, which is applied in the anticorrosion process field of urban sewer pipelines, can solve problems such as inability to effectively ensure uniform coating on the inner wall of the pipeline, numerous anticorrosion steps, and inconvenient manual coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

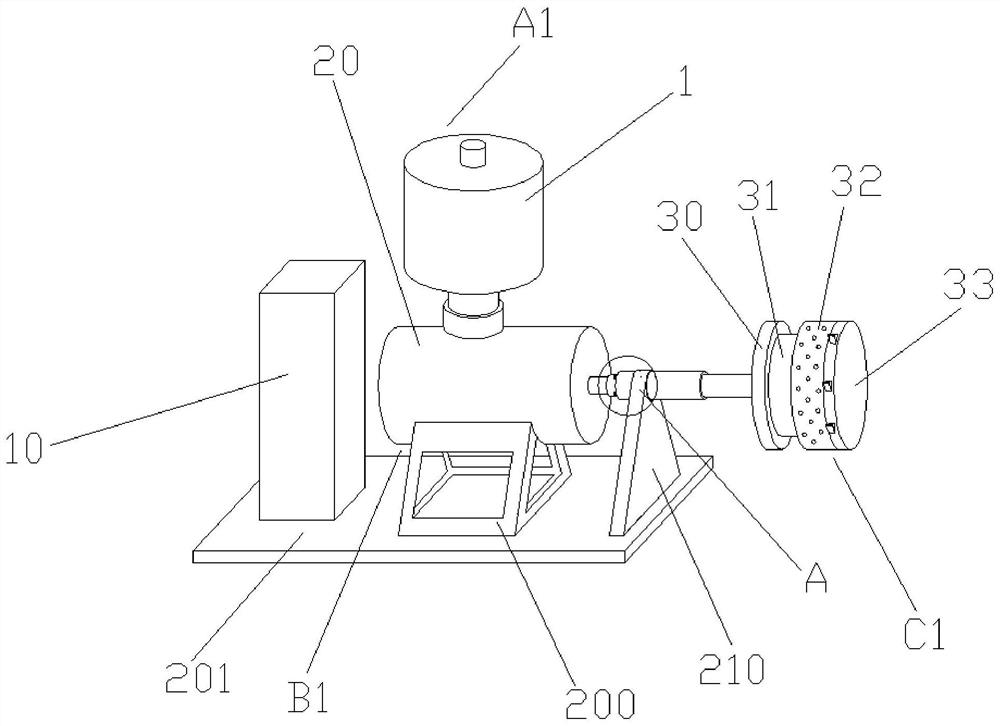

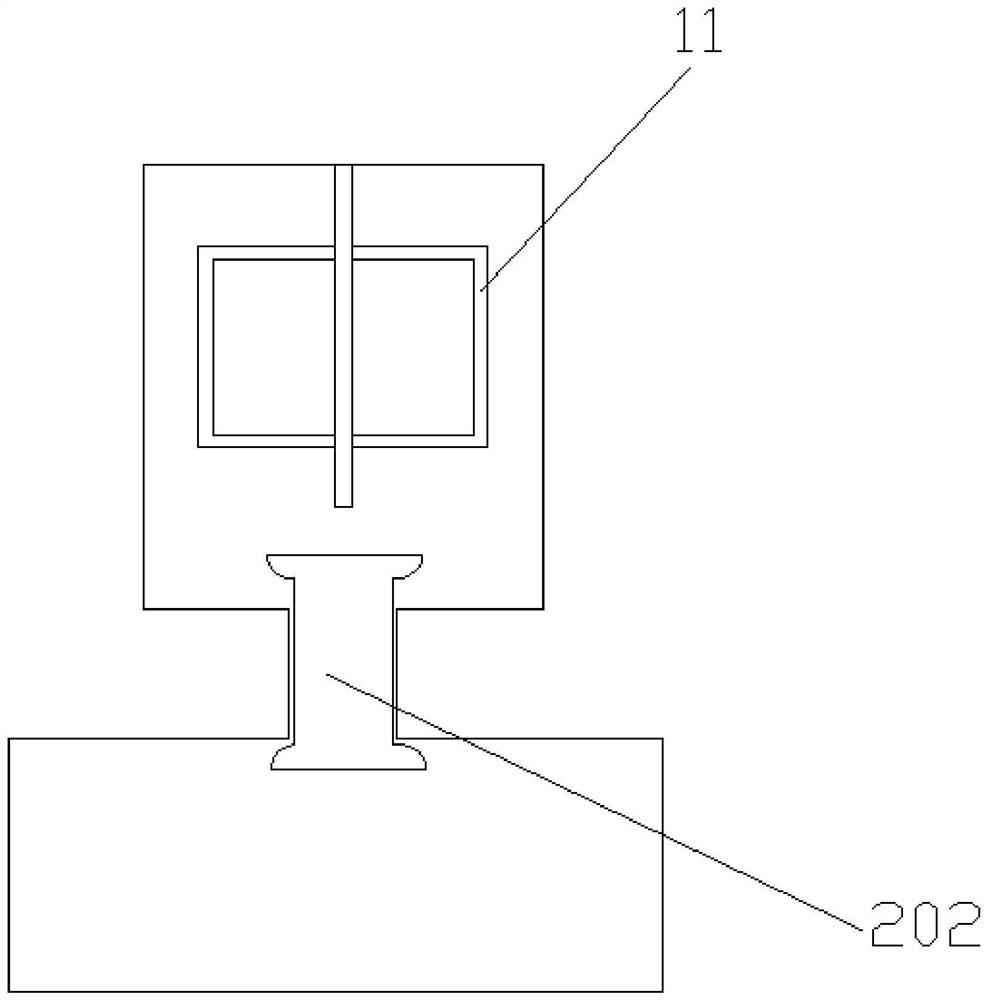

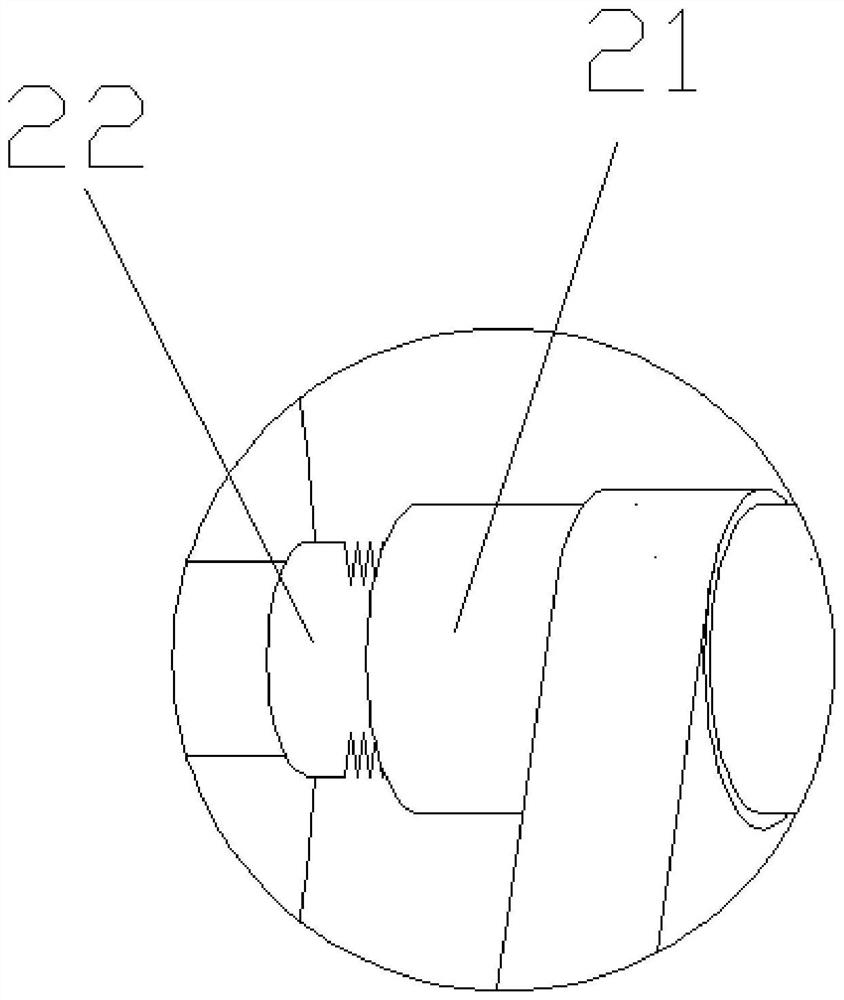

[0035] Attached below figure 1 - attached Image 6 The present invention is further described with embodiment:

[0036] An anticorrosion process method for urban sewer pipes, the method comprising the following steps:

[0037] A. Slurry mixing: Mix and stir various anti-rust materials through the mixing equipment A1 to obtain a suitable anti-rust slurry;

[0038] B. Slurry delivery: The slurry treated by A is transported to the spraying equipment through the slurry delivery equipment B1;

[0039] C. Pipeline anti-corrosion: use anti-corrosion equipment C1 to derust and polish the inner wall of the pipeline to make the inner wall of the pipeline ready for spraying, then spray the slurry treated in B on the inner wall of the pipeline, and finally bake the inner wall of the pipeline that has been sprayed with anti-corrosion slurry Dry;

[0040] The operation procedure in the steps A-C of the above anti-corrosion process requires the cooperation of the stirring equipment A1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com