Method for designing spoiler type processing casing of return cavity of gas compressor of ship gas turbine

A gas turbine and casing processing technology, which is applied in design optimization/simulation and other directions to achieve the effect of improving surge margin indicators, reducing resource and time consumption, and simplifying the workload of designers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in more detail below in conjunction with accompanying drawing example:

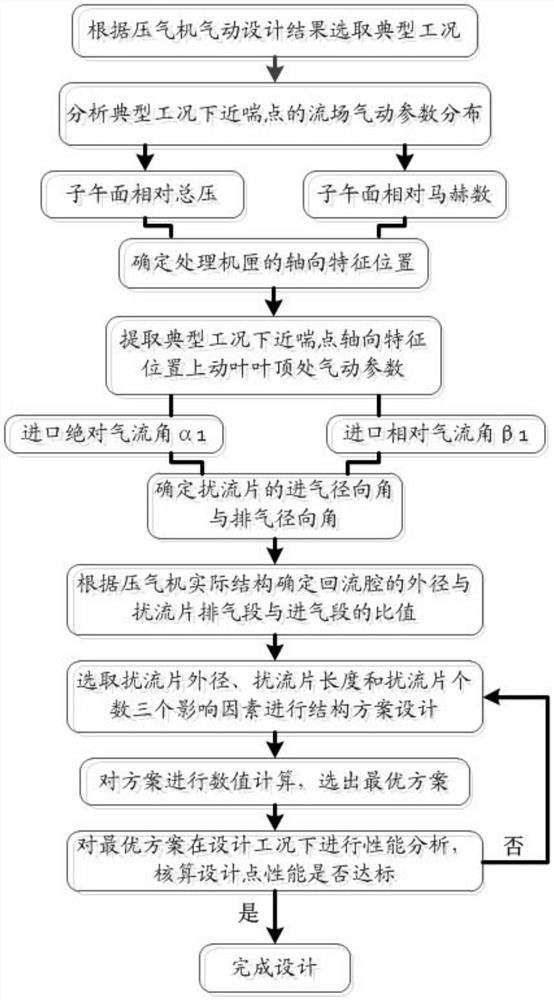

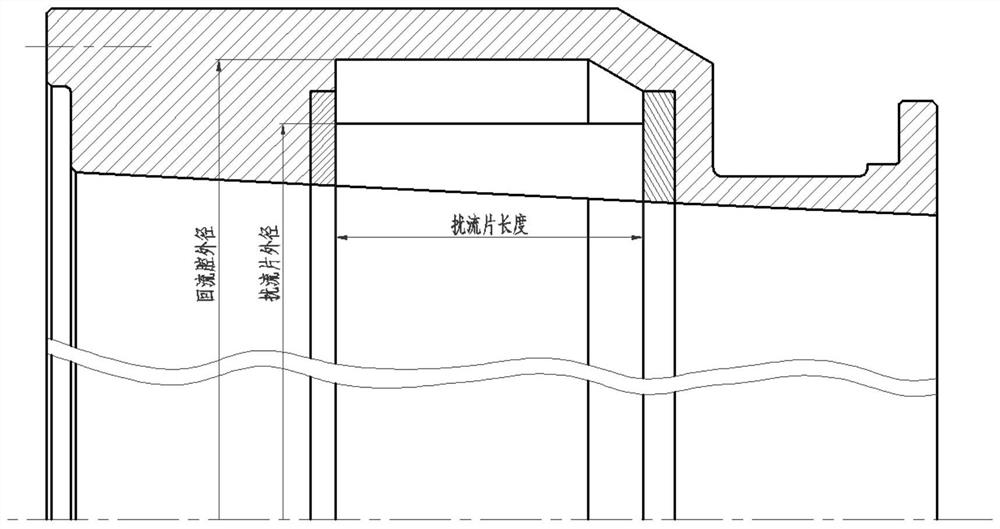

[0033] to combine Figure 1-3 According to the present invention, a specific embodiment of the design method of the gas turbine compressor return cavity of the ship-spoiler type processing casing is realized by the following steps:

[0034] Step 1: Select the typical working conditions of the return chamber-spoiler type processing casing design. According to the aerodynamic design results of the compressor, the working condition with the smallest surge margin in each working condition is selected as the typical working condition, and the general typical working condition is selected near the low speed working condition of the compressor;

[0035] Step 2: Analyze the distribution of aerodynamic parameters of the flow field near the puff point under typical working conditions, including the relative total pressure and relative Mach number distribution on the meridi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com