Multi-column inlet guide vane/variable stator vane power exponential type combined regulation and control rule design method for multistage axial flow compressor of ship gas turbine

An axial flow compressor, gas turbine technology, applied in mechanical equipment, machine/engine, pump control, etc., can solve the problems of joint control angle law design difficulty, increase in quantity and other problems, achieve engineering design application, reduce resource and time consumption , the effect of simplifying the workload of designers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in more detail below in conjunction with accompanying drawing example:

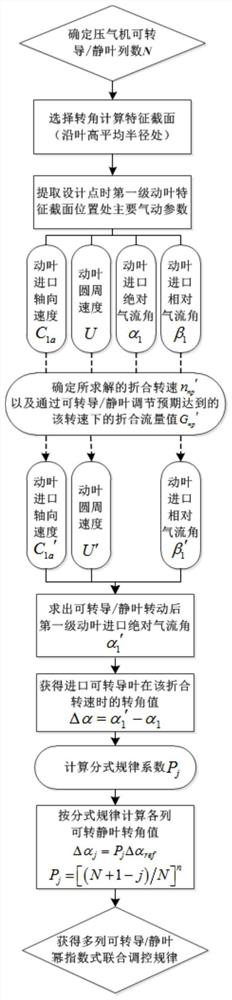

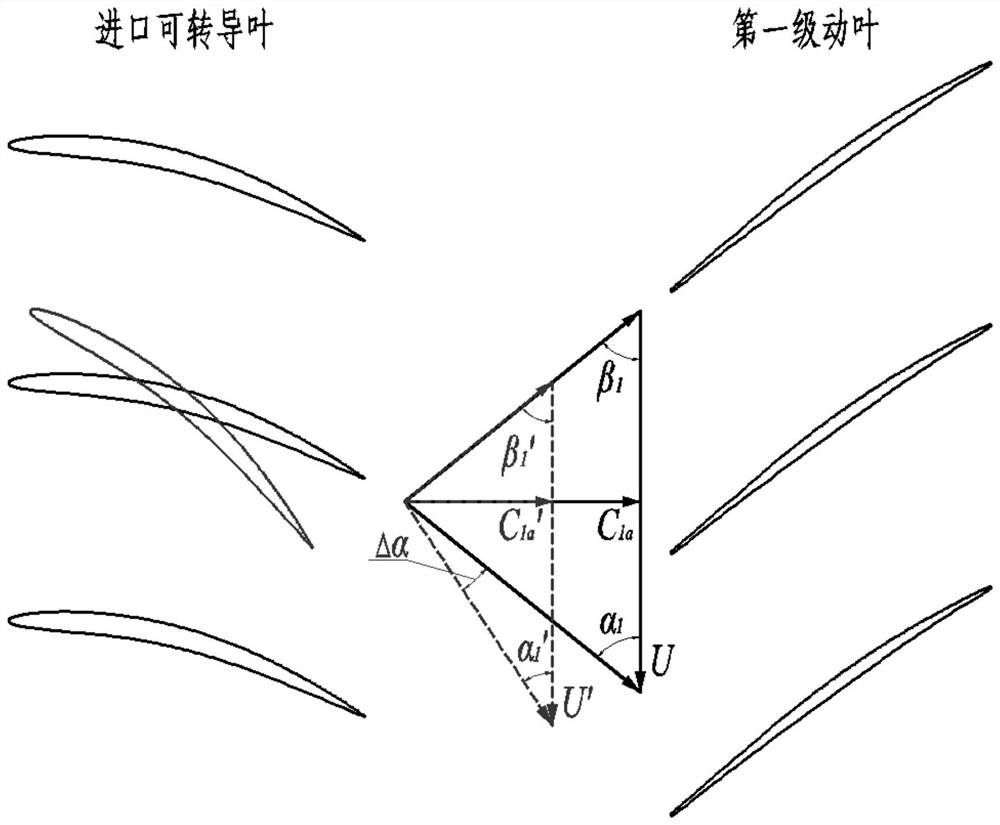

[0038] combine Figure 1-2 , the specific steps of the multi-row transducible / stator blade power exponential joint control law design method for a multi-stage axial flow compressor of a ship gas turbine of the present invention are as follows:

[0039] Step 1: Select the average radius position along the height of the blade as the characteristic cross-section for the calculation of transducible / stator blade rotation angle, and the average radius value can be calculated by arithmetic mean method or area weighted mean method;

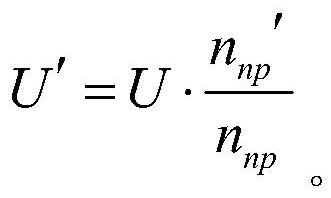

[0040] Step 2: Extract the main aerodynamic parameters at the characteristic cross-section position of the first-stage rotor blade at the inlet of the compressor at the design point (at this time, all transducible / stator blade rotation angles are 0°), including: inlet axial velocity C 1a , peripheral speed U, inlet absolute airflow angle α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com