Aluminum joint ball pin assembly and production process thereof

A production process and joint ball technology, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the waste of joint ball pin and bearing shell costs, shorten the service life of the joint ball pin assembly, and cannot Realize problems such as the replacement of elastic bodies separately, and achieve the effects of simplifying the production process, improving the convenience of use, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

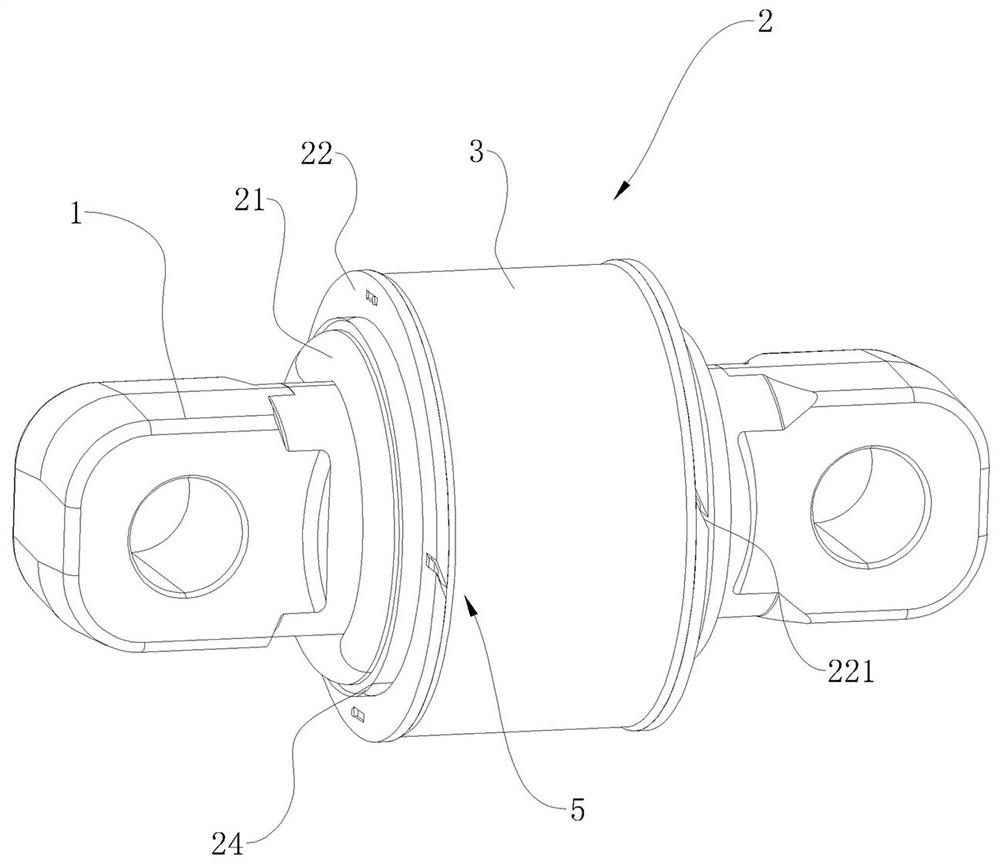

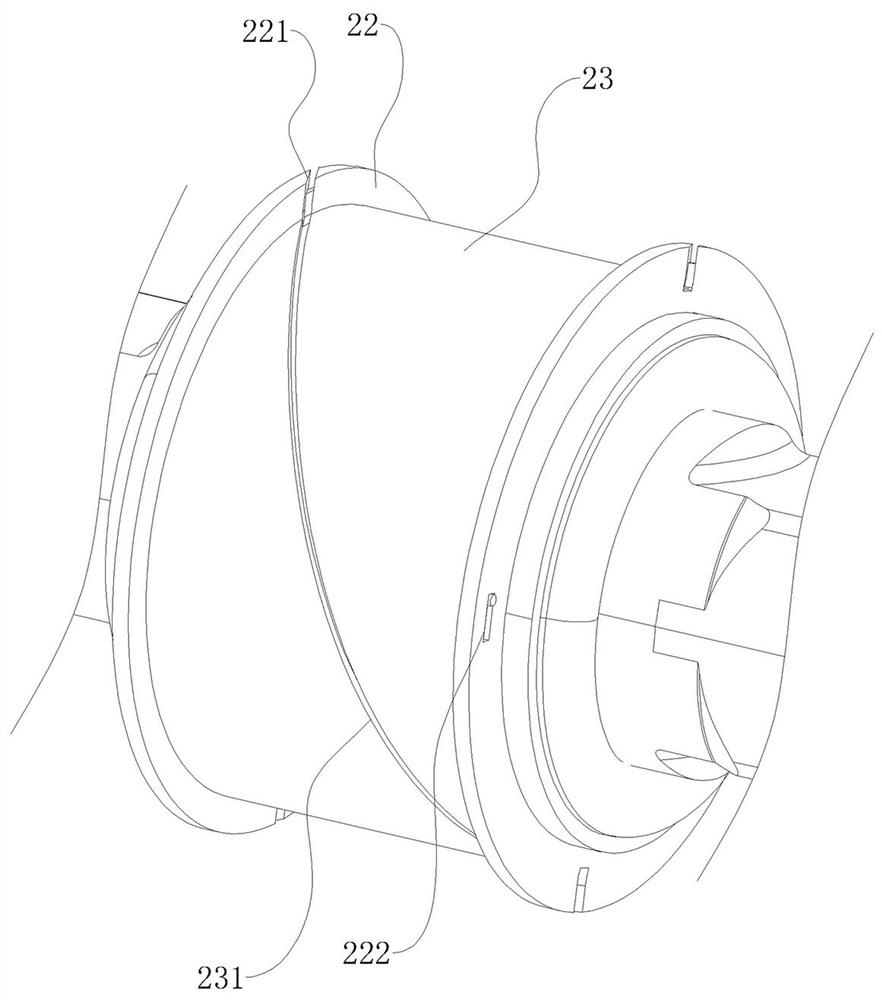

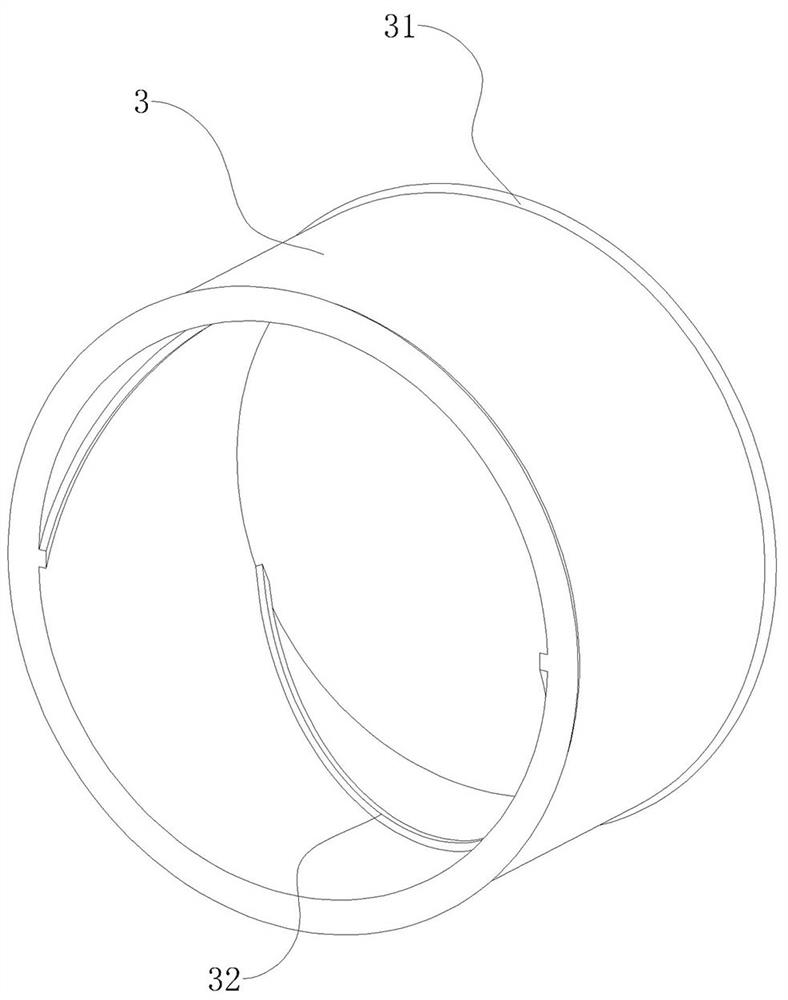

[0042] The embodiment of the present application discloses an aluminum joint ball pin assembly. refer to figure 1, the aluminum joint ball pin assembly includes the joint ball pin, the joint ball pin includes the pin body 1 and the bearing shell 2, both the pin body 1 and the bearing shell 2 are made of aluminum material, so as to realize the weight reduction of the joint ball pin; the bearing shell 2 is hollow The hollow shape of the bearing shell 2 is set and adapted to the shape of the middle part of the pin body 1 , so that the bearing shell 2 is sleeved outside the middle part of the pin body 1 .

[0043] refer to figure 1 , the bearing housing 2 includes a housing 24, the housing 24 is set in a cylindrical shape, and the two ends of the housing 24 are respectively equipped with a sealing ring 21 for sealing the cavity in the housing 24, so as to realize the pin body installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com