A steel structure assembled beam-column joint connection device

A technology of beam-column joints and connecting devices, which is applied in the direction of building construction and construction, can solve the problems of reducing construction speed and many processes, and achieve the effects of speeding up installation progress, ensuring structural safety, and reducing transportation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

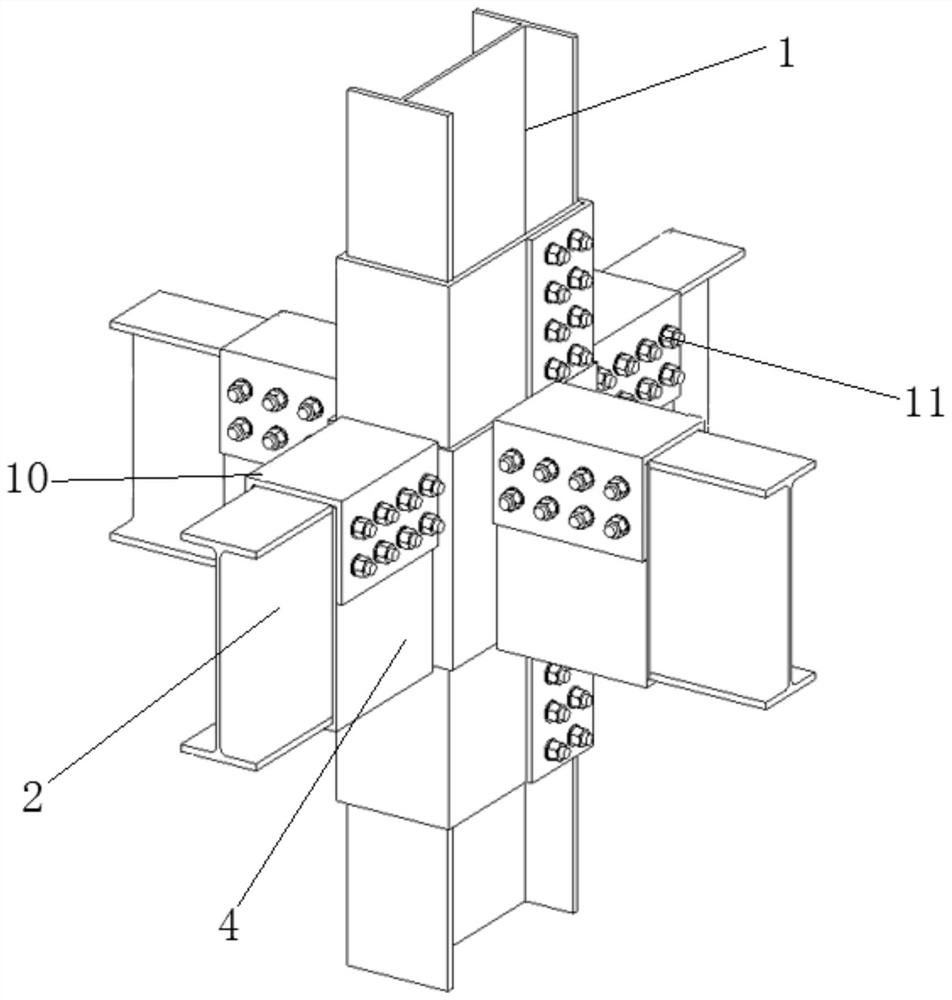

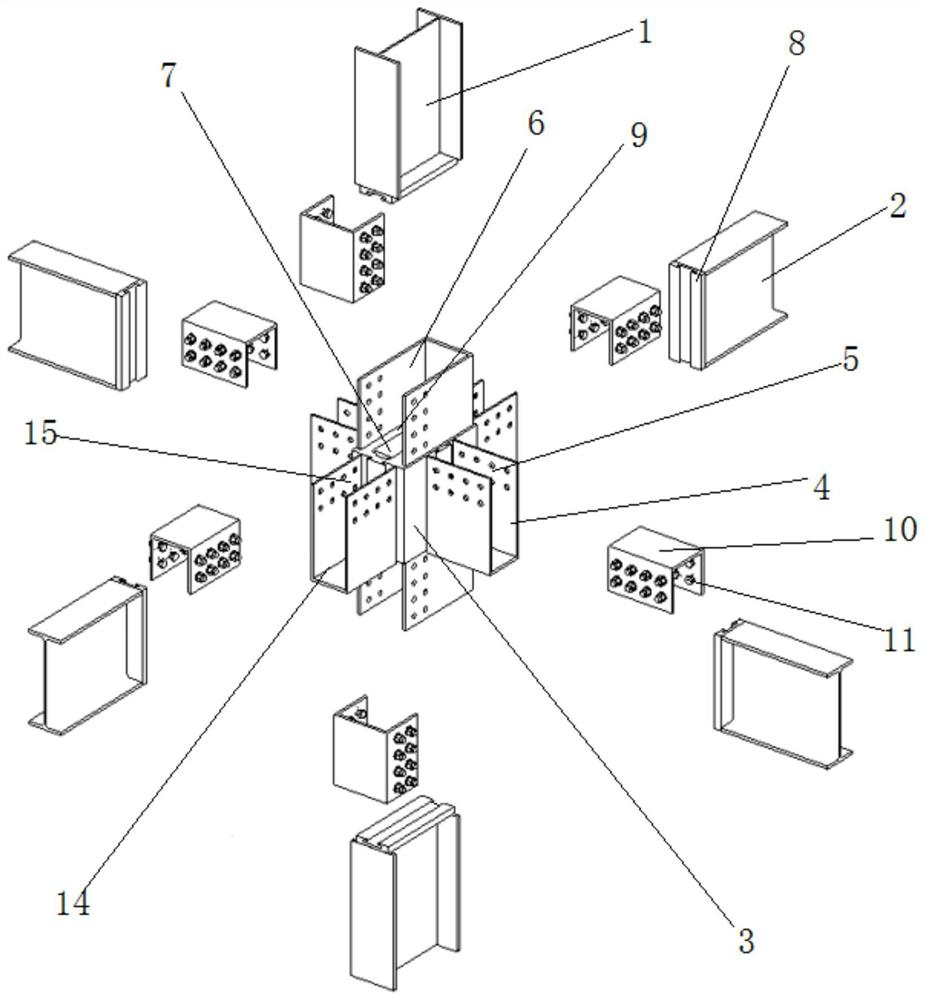

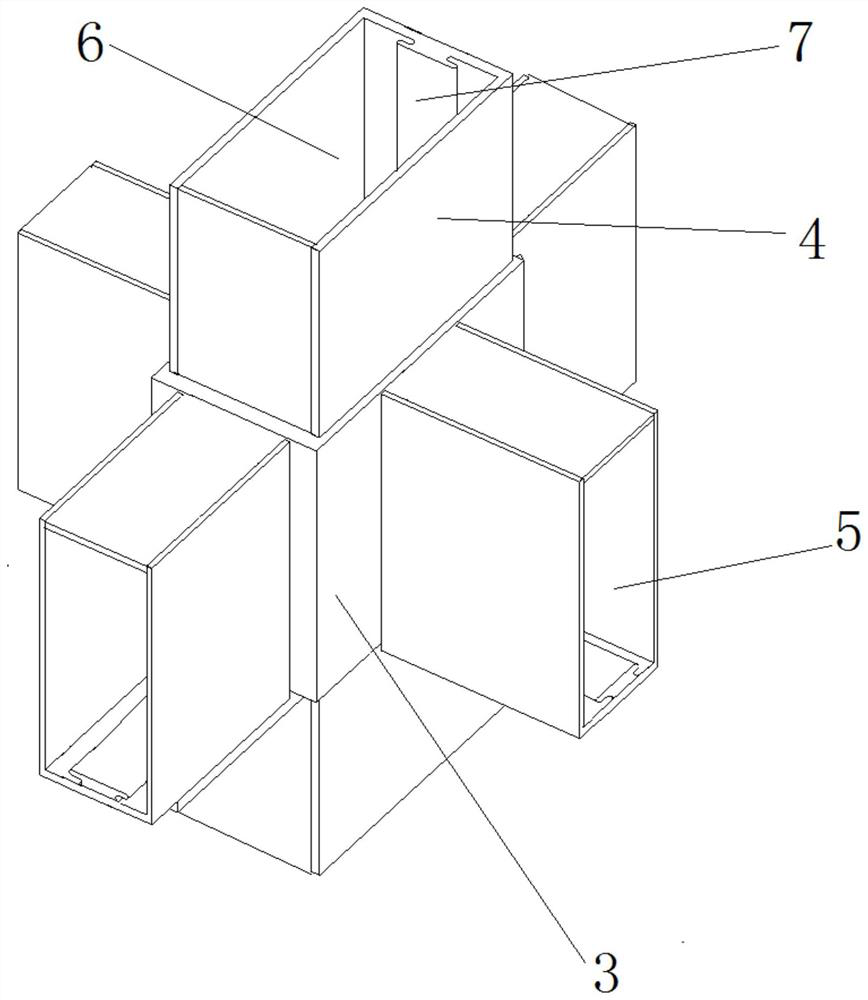

[0041] A steel structure assembled beam-column joint connecting device is used for connecting several columns 1 and several beams 2. The columns 1 and 1, the beams 2 and 2, and the beams 2 and the columns 1 are all fixedly connected through a connecting box 3, and at least two of the six directions of the connecting box 3 are provided with box-shaped connectors 4, which are provided with at least one opening 5, and the box-shaped connectors 4 are arranged on at least one inner box surface 6 perpendicular to the opening 5. The vertical column 1 and the cross beam 2 are both provided with slide rails 8 matched with the guide rails 7.

[0042] In specific setting, the fixed position of the box connector 4 and the connecting box 3 is the central surface 9, and the opening 5 is at least arranged on the surface opposite to the central surface 9. 5 The direction of the opening is determined according to the direction of the beam 2 or column 1 to be connected.

[0043] See details. Figure...

Embodiment 2

[0048] A steel structure assembled beam-column node connection device is used for connecting several columns 1 and several beams 2. The columns 1 and 1, the beams 2 and 2 and the beams 2 and 1 are all fixedly connected by a connection box 3, and at least two of the six directions of the connection box 3 are provided with a box-shaped connector 4, which is provided with at least one opening 5, and at least one inner box surface 6 of the box-shaped connector 4 is provided with a guide rail 7. The vertical column 1 and the cross beam 2 are both provided with slide rails 8 matched with the guide rails 7.

[0049] In specific setting, the fixed position of the box connector 4 and the connecting box 3 is the central surface 9, and the opening 5 is at least arranged on the surface opposite to the central surface 9. 5 The direction of the opening is determined according to the direction of the beam 2 or column 1 to be connected.

[0050] See details. Figure 4 The box connector 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com