Automatic replacement device for new energy sky train power battery pack

A power battery pack and automatic replacement technology, applied in transportation and packaging, charging stations, electric vehicles, etc., can solve the problems of low replacement efficiency, frequent replacement of battery packs, unfavorable and efficient switching of power sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

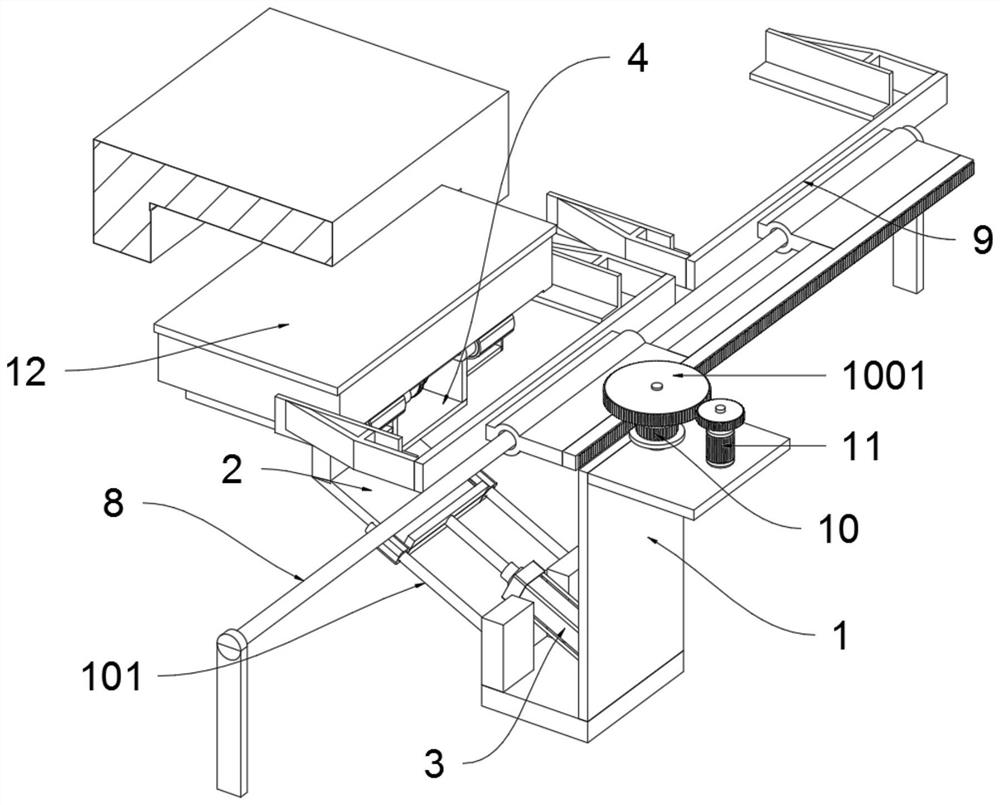

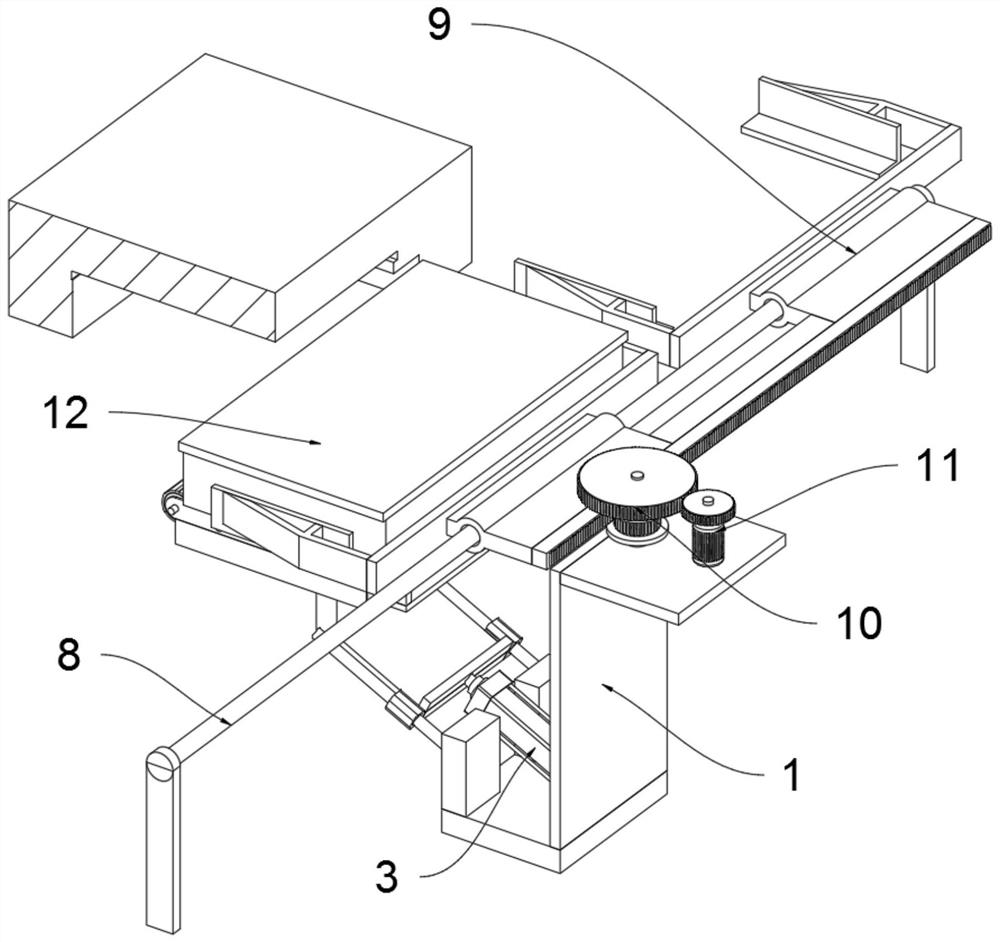

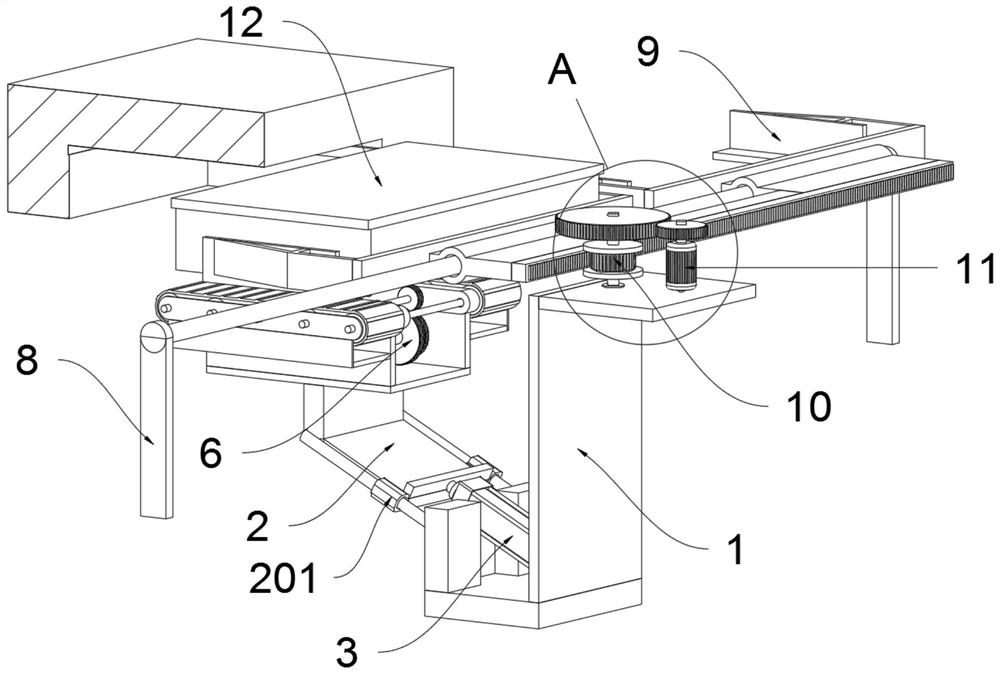

[0033]Appendfigure 1 AdherentFigure 8Down:

[0034]The present invention provides a new energy source empty iron power battery pack automatic replacement device including a total bracket 1, a telescopic driving member 3, a bracket 4, a push-pull belt 5, a conversion shaft 6, a driver a 7, a robot 9, a limit drive Wheel 10, driving member two 11, lithium battery pack 12; inner sliding connection with lifting frame 2; the housing of the telescopic driving member 3 is fixed to the total bracket 1, and the output shaft end of the telescopic driving member 3 is fixedly connected The lower end of the lift frame 2; the lower surface of the bracket 4 is connected to the upper end of the lift 2 by welding; the side frame of the pumping conveyor belt 5 is fixed above the bracket 4 by welding; the conversion shaft 6 is transferred to the bracket through the bearing 4 of the groove; the drive member is fixed to the upper side of the bracket 4, and the output shaft of the drive member 7 is engaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com