Drilling machine for dust-free woodworking for high-grade furniture and machining process of drilling machine

A furniture and high-end technology, which is applied to the drilling machine for dust-free woodworking processing of high-end furniture and its processing technology, can solve the problems of low environmental protection effect, low work efficiency, and difficulty in cleaning, so as to avoid dust, improve production efficiency, and improve filtration. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

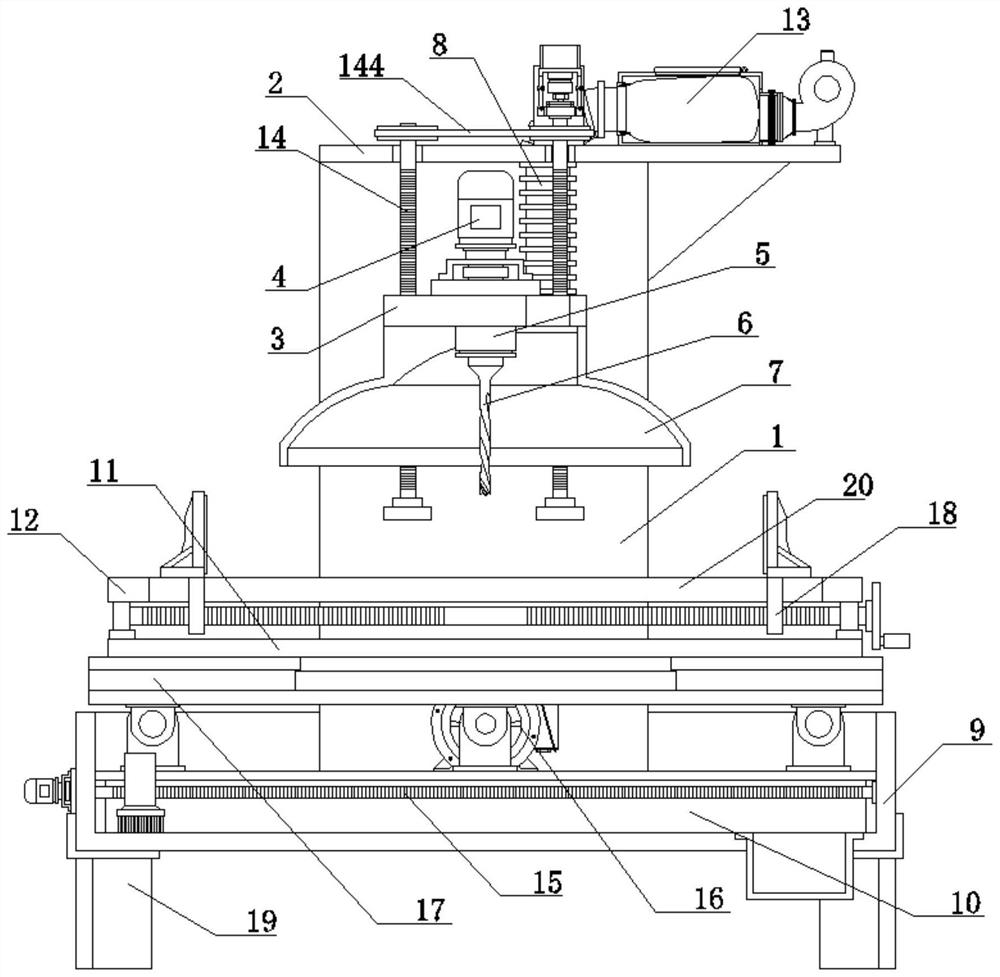

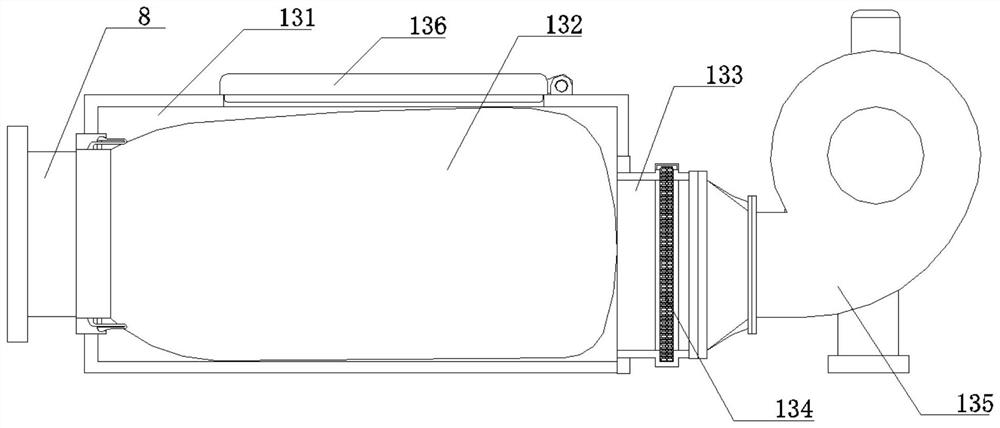

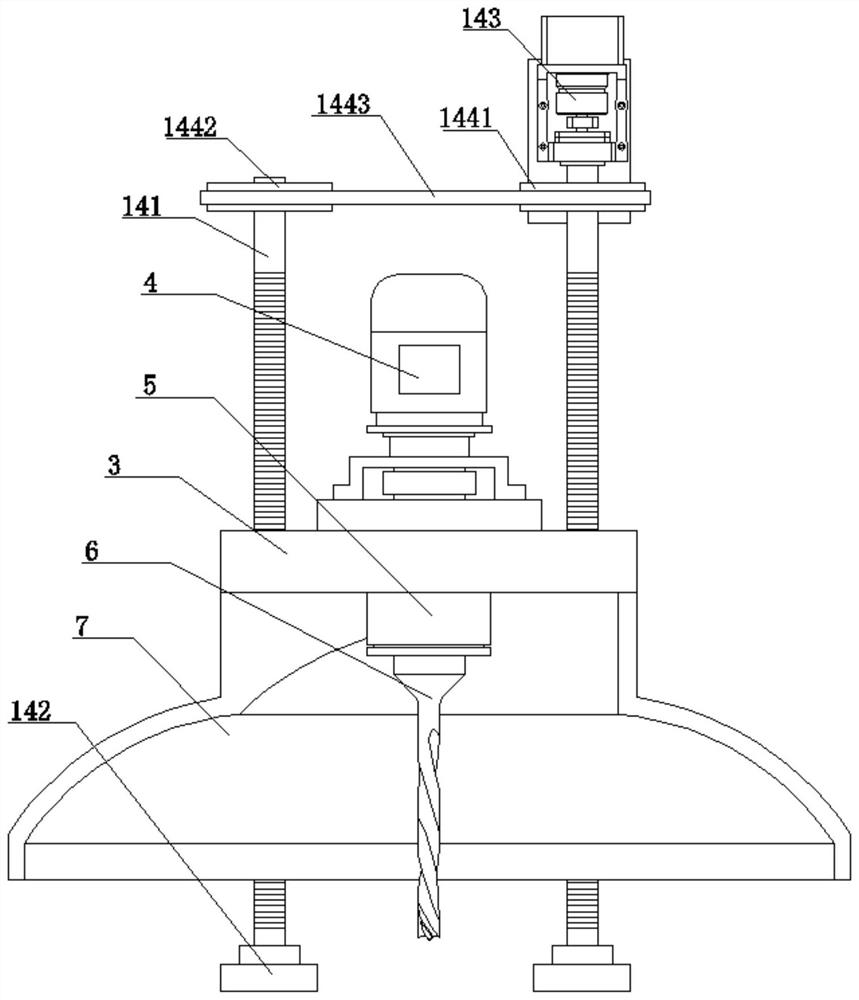

[0040] A drilling machine for dust-free woodworking processing of high-grade furniture, comprising a support frame 1, the upper end of the support frame 1 is fixedly connected with a top plate 2, the upper end of the top plate 2 is provided with a dust removal assembly 13, and the support frame 1 is provided with a drill feed mechanism 14 , the drill feeding mechanism 14 is connected with a mounting base 3, the upper end of the mounting base 3 is fixedly connected with a drilling motor 4, the lower end of the mounting base 3 is rotatably connected with a tool holder 5, and the cutter base 5 is detachably and fixedly connected with a drill 6 , the upper end of the tool holder 5 is fixedly connected with the output shaft of the drilling motor 4 through a coupling, the outer periphery of the lower end of the mounting base 3 is fixedly connected with a dust collection cover 7, and the dust removal assembly 13 is connected with one end of a dust suction hose 8 for dust collection. T...

Embodiment 2

[0047] A processing technology of a high-grade furniture dust-free woodworking drilling machine, specifically comprising the following steps:

[0048] Step 1, place the plate on the surface of the workbench 12, and turn the crank handle 183 to drive the two-way screw 181 to rotate, and the two-way screw 181 drives two splints 185 to clamp and fix the plate;

[0049] Step 2, start the X-axis feed motor 163, the X-axis feed motor 163 drives the third screw 161 to rotate, the third screw 161 drives the groove plate 171 to move through the nut seat 164, and drives the plate to move;

[0050] Step 3, grasp the moving seat 11, move the moving seat 11 along the direction of the Y-axis chute 172, drive the part to be drilled of the plate to move to the bottom of the drill bit 6 through the moving seat 11, and perform tool setting;

[0051] Step 4, after the tool setting is completed, the drilling motor 4 is started, and the drilling motor 4 drives the drilling tool 6 to rotate through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com