Method for arranging bobbins

A bobbin and tube management technology, applied in the field of bobbin finishing, can solve the problems of not being able to meet the requirements of use, heavy workload, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

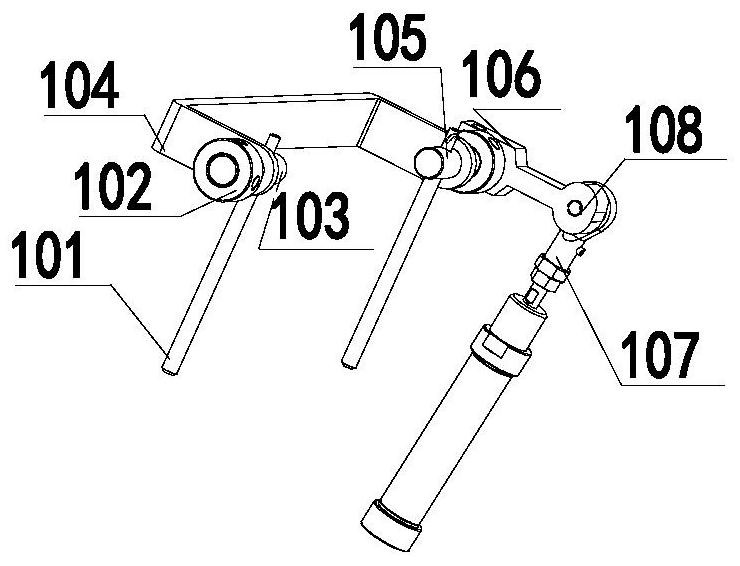

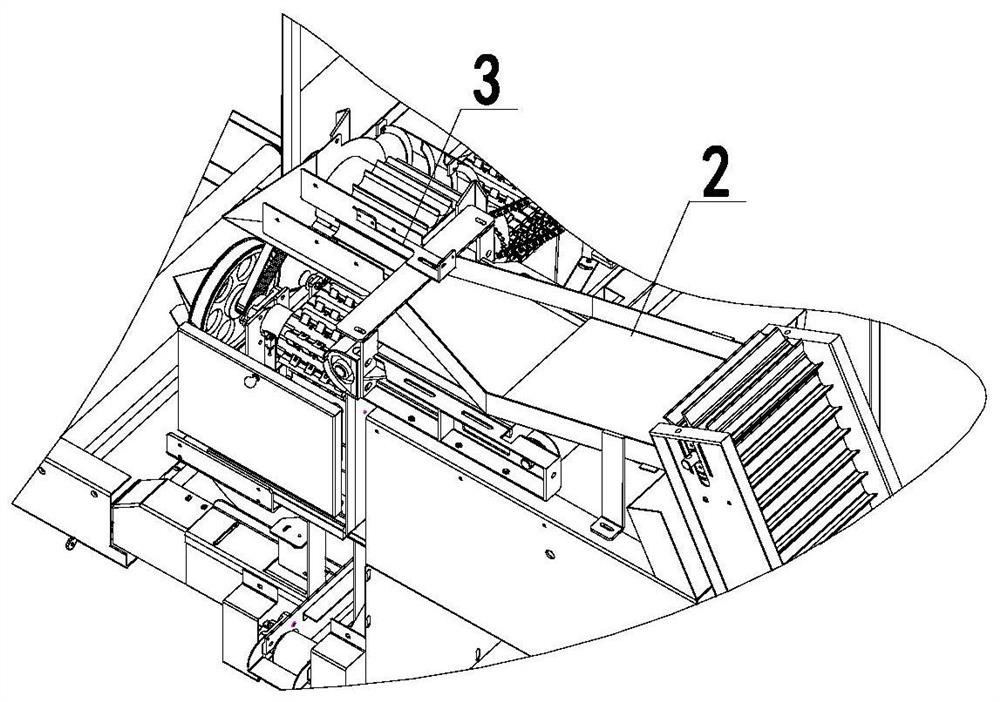

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-6 As shown, the present invention is a method for finishing bobbins.

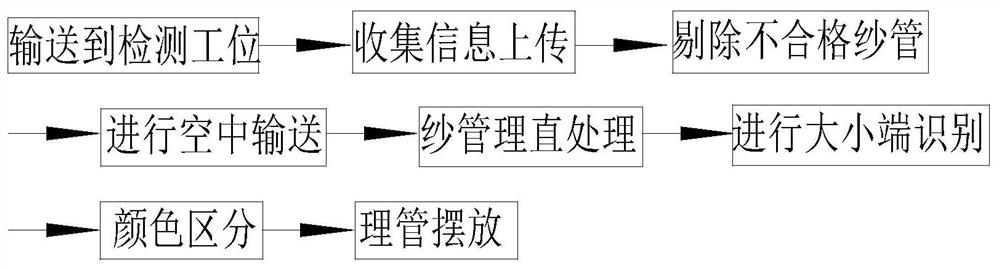

[0031] The method for finishing bobbin described in the present embodiment comprises the following steps:

[0032] 1) Transport the bobbins to the conveyor belt in the tube lifting separator, place a bobbin setting on each lifting bar on the conveyor belt, and raise each bobbin to the detection station.

[0033] 2) The yarn bobbin is detected by the sensor switch and the detection mechanism. The detection mechanism is the camera mechanism and the laser beam sensor. The sensor switch has no signal within the set time, and the camera mechanism detects and takes pictures of each bobbin. Generally, the The bobbin with a diameter ≥ 28mm is called a large bobbin, which is sensed by a laser beam sensor and the information is uploaded. Collect the inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com