Adhesive fluff filtering device for textile wastewater treatment

A textile waste water and filter device technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy clogging of fine-pore filter nets, low efficiency of wastewater treatment, unsatisfactory filtration effect, etc., and achieve easy reuse, Improved usability and ease of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

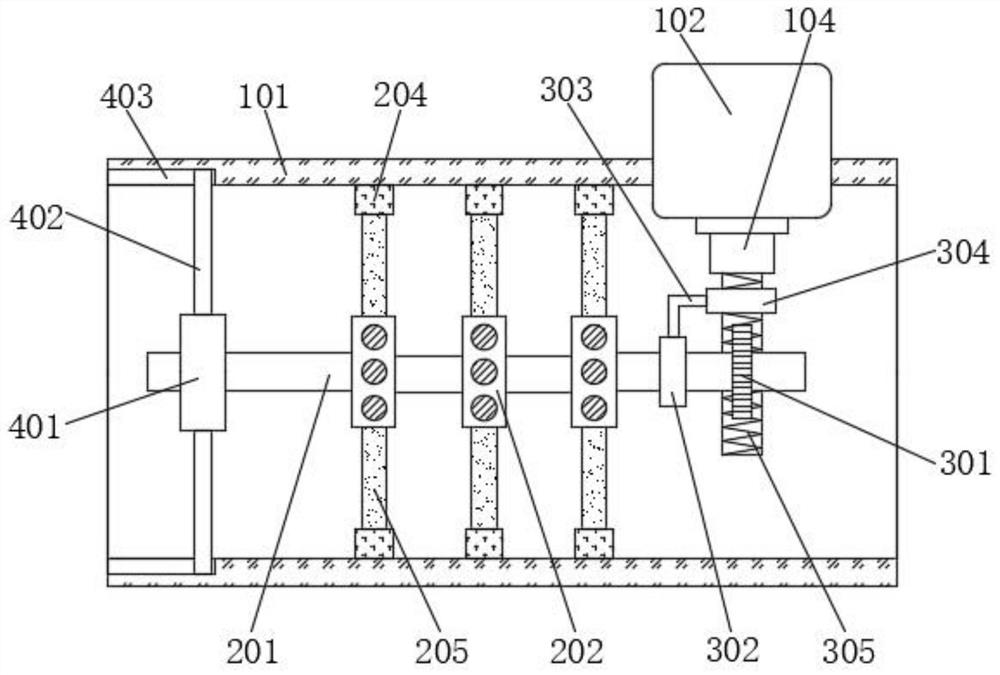

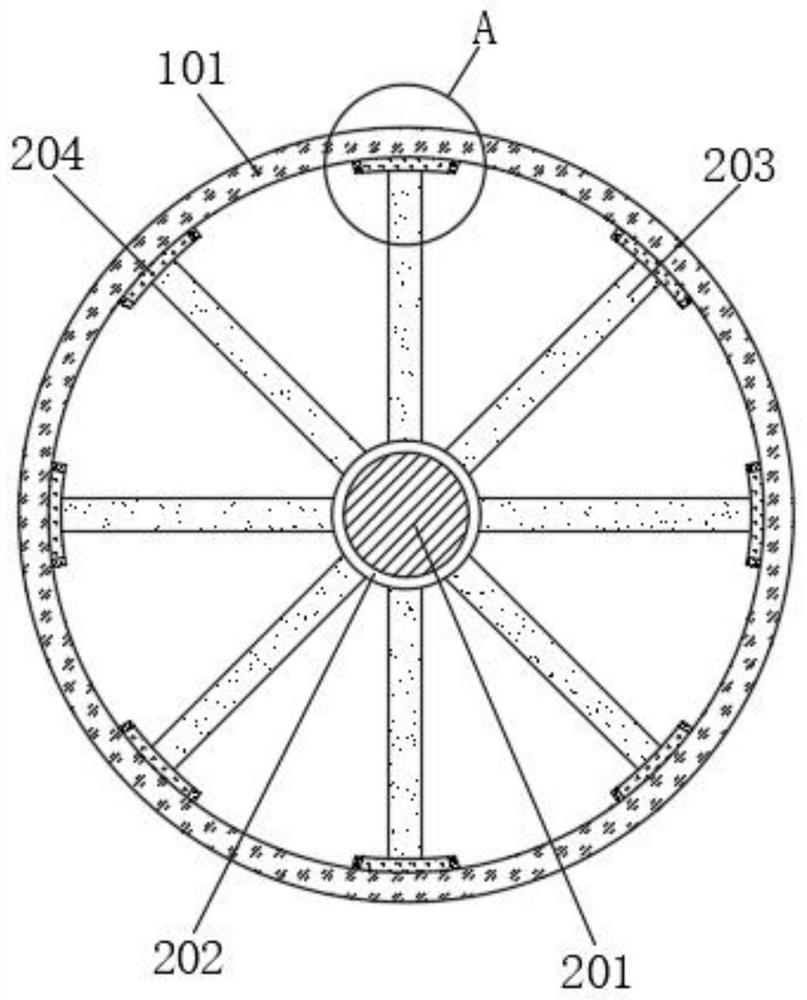

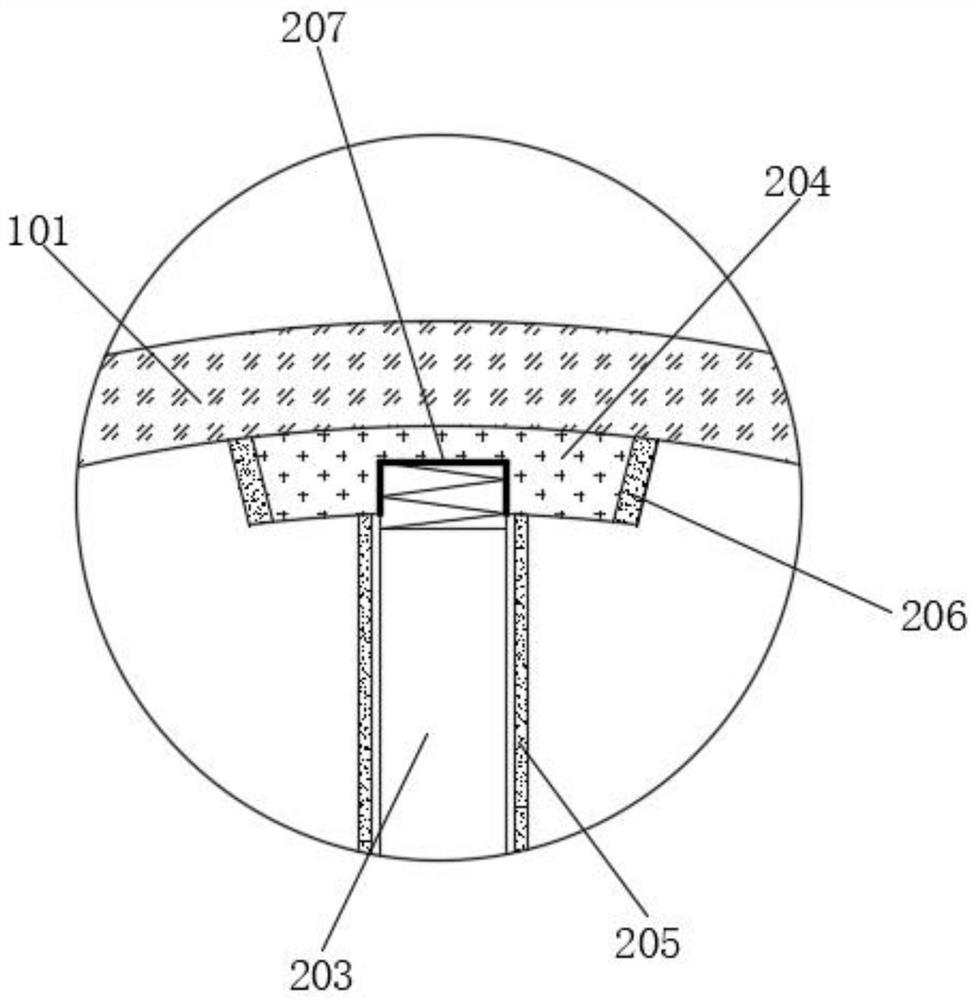

[0042] see Figure 1-4 , an adhesive flock filter device for textile wastewater treatment, comprising a filter treatment pipe 101, a sealed motor box 102 is inlaid on the outer wall of the top of the filter treatment pipe 101, and a drive motor 103 is fixedly installed in the sealed motor box 102, and the drive motor The output end of 103 is fixedly connected with a drive shaft 104, the drive shaft 104 penetrates the bottom outer wall of the sealed motor box 102 and extends into the filter processing tube 101, and a rotary seal ring is provided at the connection between the drive shaft 104 and the outer wall of the sealed motor box 102 105. The setting of the rotary sealing ring 105 can improve the tightness of the connection between the drive shaft 104 and the outer wall of the sealed motor box 102, and prevent waste water from entering the sealed motor box 102, resulting in damage to the drive motor 103. Attached rod group, the adhesive rod group includes a central driven ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com