Composite flavor beef tallow and production process thereof

A production process and technology of butter, which is applied in the field of food processing, can solve problems such as loss, loss of oil, and weakening of the compound flavor of onion and fragrant, and achieve the effects of reducing energy consumption, cost saving, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example is an example of the selection and preparation of tallow raw materials.

[0034] Conduct a selection study on tallow fat raising material:

[0035] Select three varieties of cattle, yak, and buffalo, and carry out combined tests on the three parts of sirloin oil, tripe oil, and beef fat oil. At least 9 groups of parallel tests are carried out. Through the analysis of components, melting point, flavor, and solid fat content, the final Choose yak tripe oil as the raw material of oil.

[0036] Research on the cooking process of yak tripe oil:

[0037] Temperature gradient: a gradient test every 10-20°C, boil at 120-180°C; boil time: boil for 1-3h with a gradient every hour or every half hour, and determine the boil temperature through at least 12 groups of boil process research 160°C, time 2h is preferred.

Embodiment 2

[0039] This example is an example of compound flavor butter raw material proportioning.

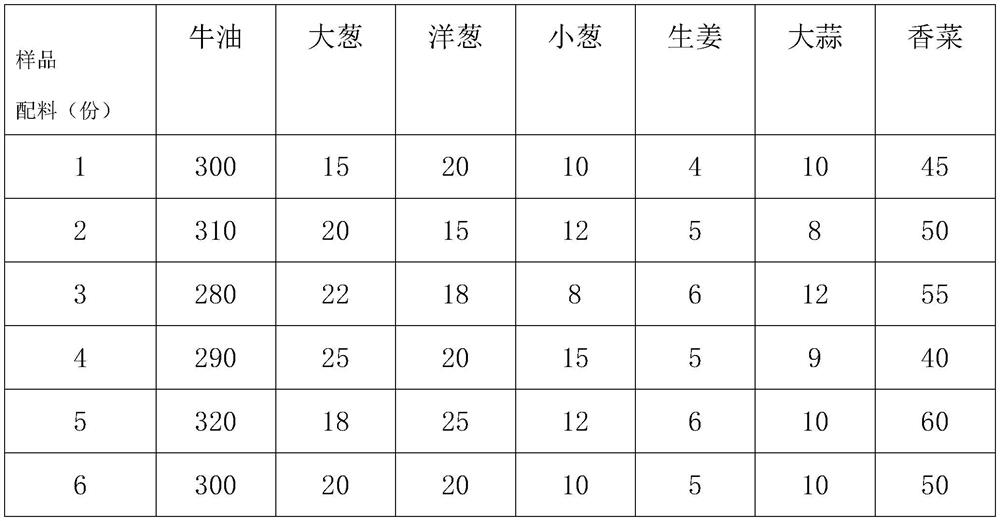

[0040] A compound flavored butter, the ingredients of which are 280-320 parts by weight of butter, 15-25 parts of green onions, 15-25 parts of onions, 8-15 parts of shallots, 4-6 parts of ginger, 8-12 parts of garlic, Coriander 40-60 parts.

[0041] At least 72 groups of formula tests have been carried out, and the following are the selected representative ratios:

[0042]

[0043] The various data of the test show that the sixth group of formulas is preferred, and its ingredients are 300 parts by weight of butter, 20 parts of green onions, 20 parts of onions, 10 parts of shallots, 5 parts of ginger, 10 parts of garlic, and 50 parts of parsley.

Embodiment 3

[0045] This embodiment is a production process embodiment. Multiple groups of tests were carried out using the 6 groups of raw material proportioning samples in Example 2 respectively.

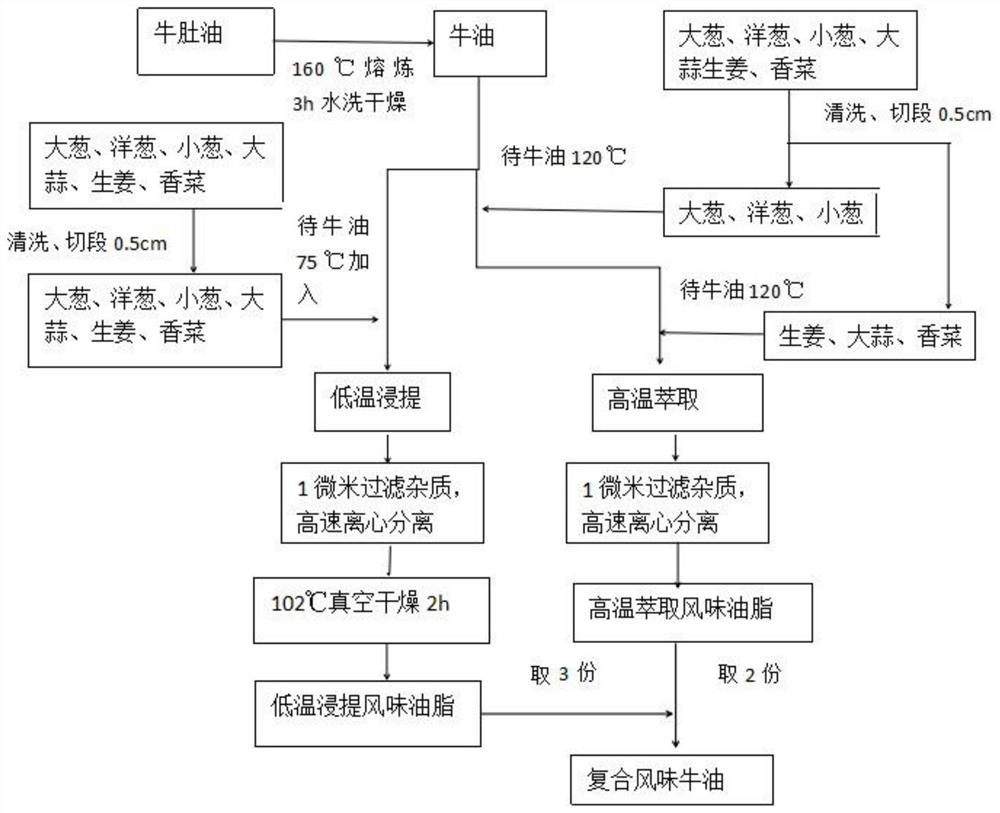

[0046] The production technology of compound flavor butter, comprises the steps:

[0047] 1) Raw material preparation: melt, wash and dry the butter, wash the scallions, onions, shallots, ginger, garlic and parsley, and cut them into 0.5cm sections;

[0048] 2) Low-temperature extraction: When the treated butter in step 1) is 75°C, add washed and cut green onions, onions, shallots, ginger, garlic and parsley, mix well, and extract at a temperature of 55-85°C for 2-5 hours , after removing impurities, vacuum-dry at 102°C for 1.5 hours to dry the water, and obtain low-temperature extraction flavor oil;

[0049] 3) High-temperature extraction: When the butter treated in step 1) is 120°C, add washed and cut green onions, onions, shallots, ginger, garlic and coriander, mix well, and extract at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com