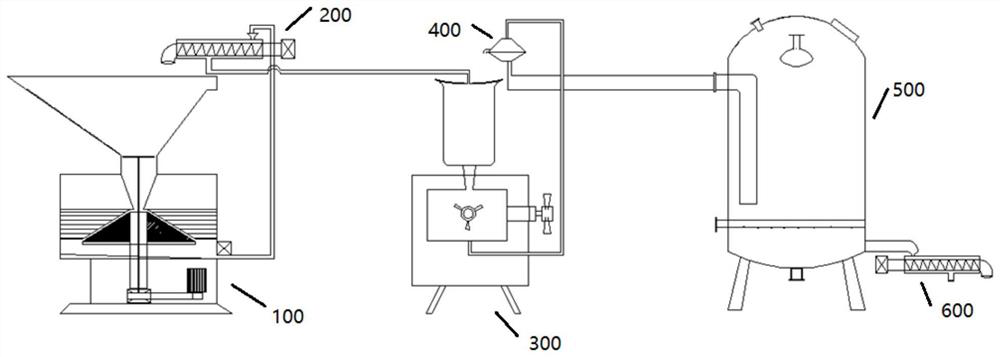

Circulating thick liquid grinding system and circulating thick liquid grinding method

A technology for pulping and pulping, which is applied in the field of food processing, can solve the problems of dissolution and high concentration of nutrients in unfavorable bean dregs, and achieve the effects of easy food safety, rich nutrition and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

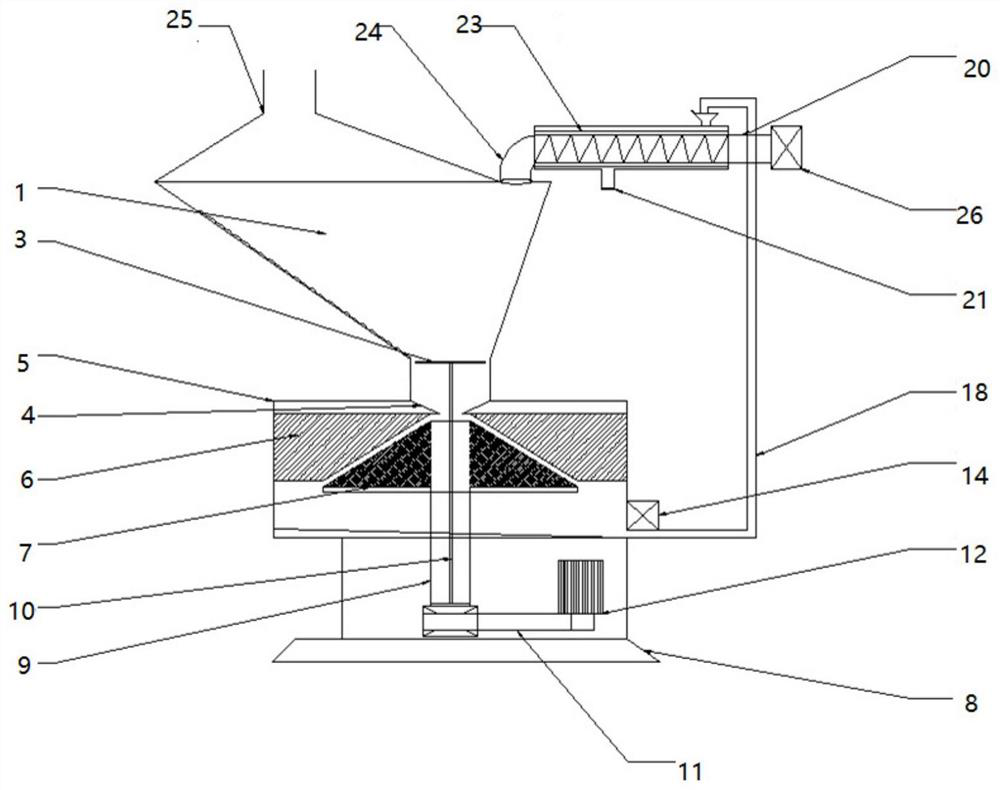

Method used

Image

Examples

Embodiment approach

[0108] One embodiment is that the specific steps of a circulating refining method include:

[0109] Step 1, removing impurities: select 50kg of soybeans, and remove impurities such as soil, mud, iron, plastics, etc. in the soybean raw materials;

[0110] Step 2, washing: washing soybeans until clean;

[0111] Step 3, soaking beans: soak the soybean raw material in water for 8 hours, when the water content of the wet beans meets the weight ratio of wet beans and unsoaked dry beans is 2:1, stop soaking to obtain 100kg wet beans;

[0112] Step 4, washing beans: rinse the soaked soybean raw materials;

[0113] Step 5, refining: the soaked soybeans, beans and water are ground into pulp in the refining device according to the ratio of 1:7, and the slag after passing through the refining separation component continues to enter the refining device for grinding, Get 900kg soybean milk;

[0114] Step 6, fine refining: the soymilk filtered by the refining and separating component ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com