Production line adaptability quantitative evaluation method

A quantitative evaluation and adaptive evaluation technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of no unified and effective quantitative evaluation methods, and achieve a reliable frequency distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

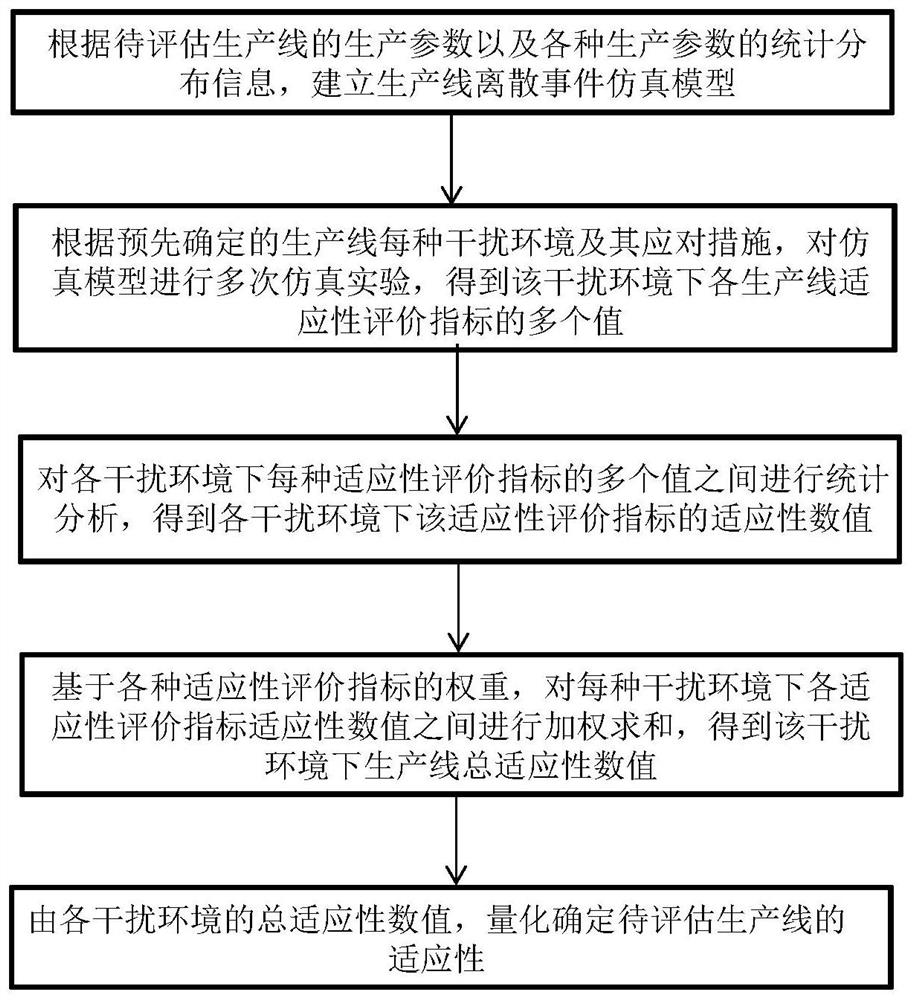

[0046] A quantitative evaluation method for the adaptability of a production line, such as figure 1 shown, including:

[0047] According to the production parameters of the production line to be evaluated and the statistical distribution information of various production parameters, a discrete event simulation model of the production line is established;

[0048] According to the pre-determined interference environment of the production line and its countermeasures, multiple simulation experiments are carried out on the simulation model, and multiple values of the adaptability evaluation indicators of each production line under the interference environment are obtained;

[0049] Perform statistical analysis among multiple values of each adaptability evaluation index in each interference environment, and obtain the adaptability value of the adaptability evaluation index in each interference environment;

[0050] Based on the weights of various adaptability evaluation indic...

Embodiment 2

[0124] A computer-readable storage medium, characterized in that the computer-readable storage medium includes a stored computer program, wherein when the computer program is run by a processor, the device where the storage medium is located is controlled to execute the above-mentioned one A quantitative evaluation method for the adaptability of a production line.

[0125] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com