A cabin-piercing adiabatic compression mechanism applied to an ultra-high vacuum cryogenic refrigeration system

A low-temperature refrigeration system and ultra-high vacuum technology, applied in household refrigeration devices, applications, household appliances, etc., can solve the problems of system vacuum damage, device temperature being difficult to maintain target low temperature, affecting the maintenance of ultra-high vacuum environment, etc., to avoid Damaged effect of compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content and advantages of the present invention clearer, the specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

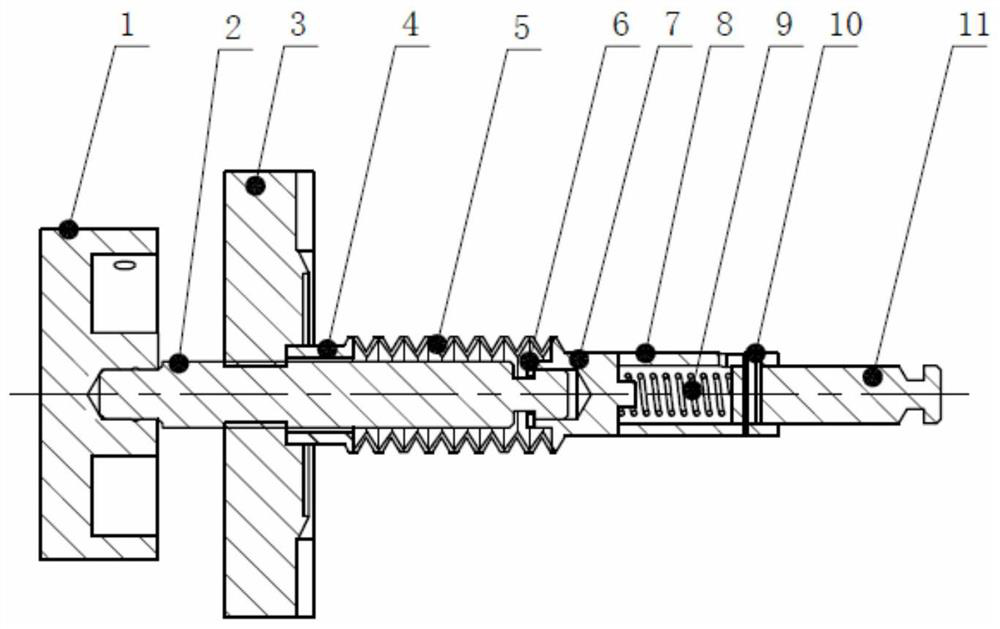

[0019] like figure 1 As shown in the figure, the cabin-penetrating adiabatic pressing mechanism of the present invention applied to an ultra-high vacuum and low-temperature refrigeration system includes an operating handwheel 1, a screw 2, a knife-edge flange 3, a bellows 5, a spring 9, and a thermal insulation column 11; the front part of the screw 2 Install the operating handwheel 1, the middle part is installed in the central threaded hole of the knife-edge flange 3 through threaded connection, the rear part is sleeved with a bellows 5, and the rear end of the screw 2 is connected to the rear joint II7 of the bellows 5; the front end of the bellows 5 is fixed On the knife-edge flange 3, the rear end is provided with a spring 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com