A Multifunctional Brake Disc Assist System

An auxiliary system and a technology for brake discs, applied in the field of brake discs, can solve problems such as easy differences in braking force, influence on braking performance, and brake thermal recession, and achieve the effects of reducing the frequency of replacement, prolonging service life, and improving the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

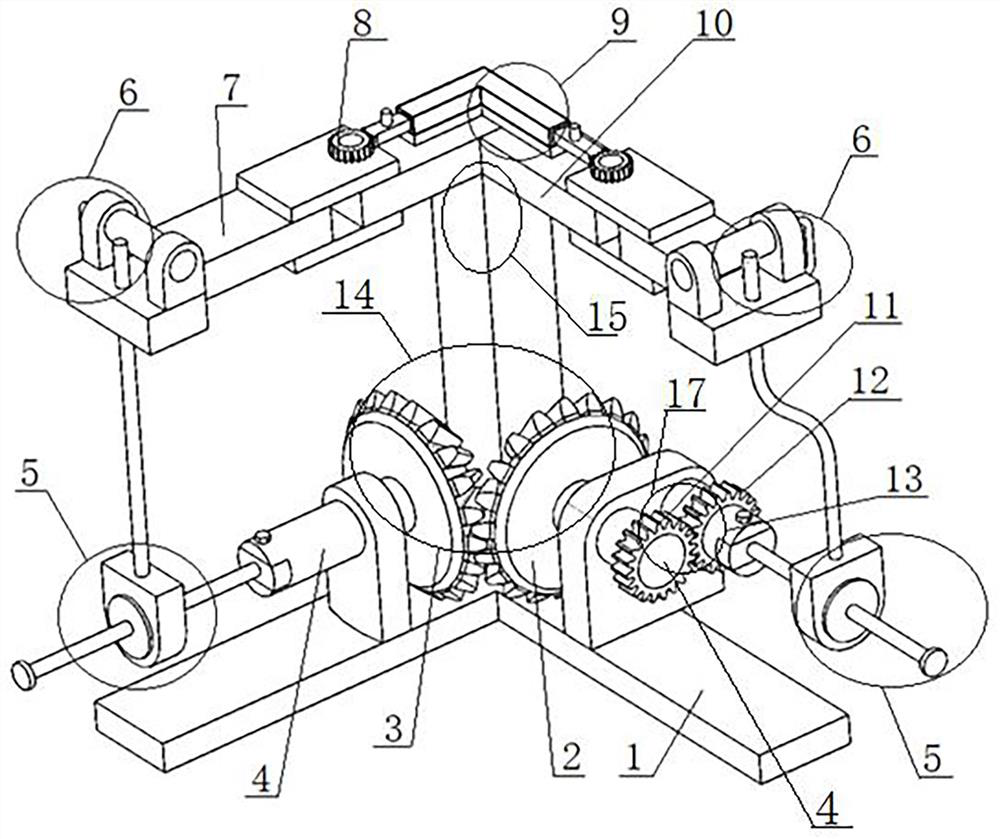

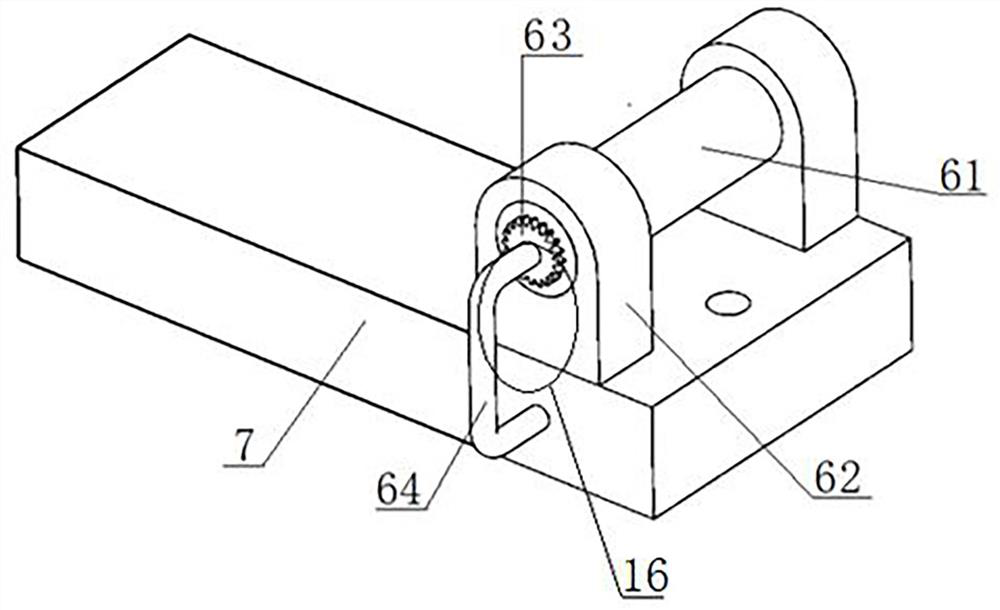

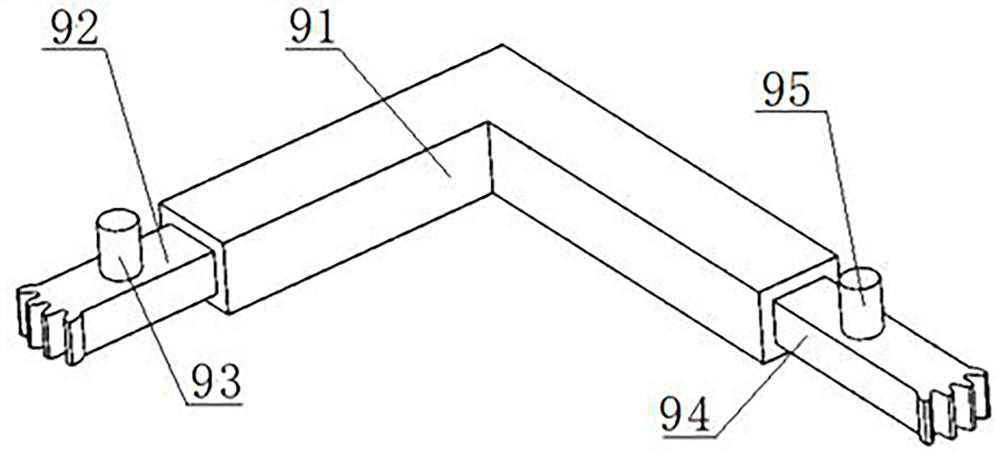

[0030] see figure 1 , a multifunctional brake disc auxiliary system, including a base plate 1, a bevel gear assembly 14 arranged on the base plate 1, two flexible shaft assemblies 5 connected with the bevel gear assembly 14, and two flexible shaft assemblies 5 respectively connected The two rotating roller assemblies 6 are respectively rotatably arranged on the bracket 15 , and the bracket 15 is also provided with a limit mechanism 9 for fixing the rotating roller assemblies 6 .

[0031] The bevel gear assembly 14 comprises a bevel gear one 2, a bevel gear two 3 meshingly connected with the bevel gear one 2, and two first drive shafts 4 pass through the centers of the bevel gear one 2 and the bevel gear two 3 respectively, the second A drive shaft 4 is horizontally hingedly arranged on the bottom plate 1 ; one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com