Automatic welding machine for terminal box

An automatic welding machine and end button box technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of interface oxidation, overheating of connections, loose screws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

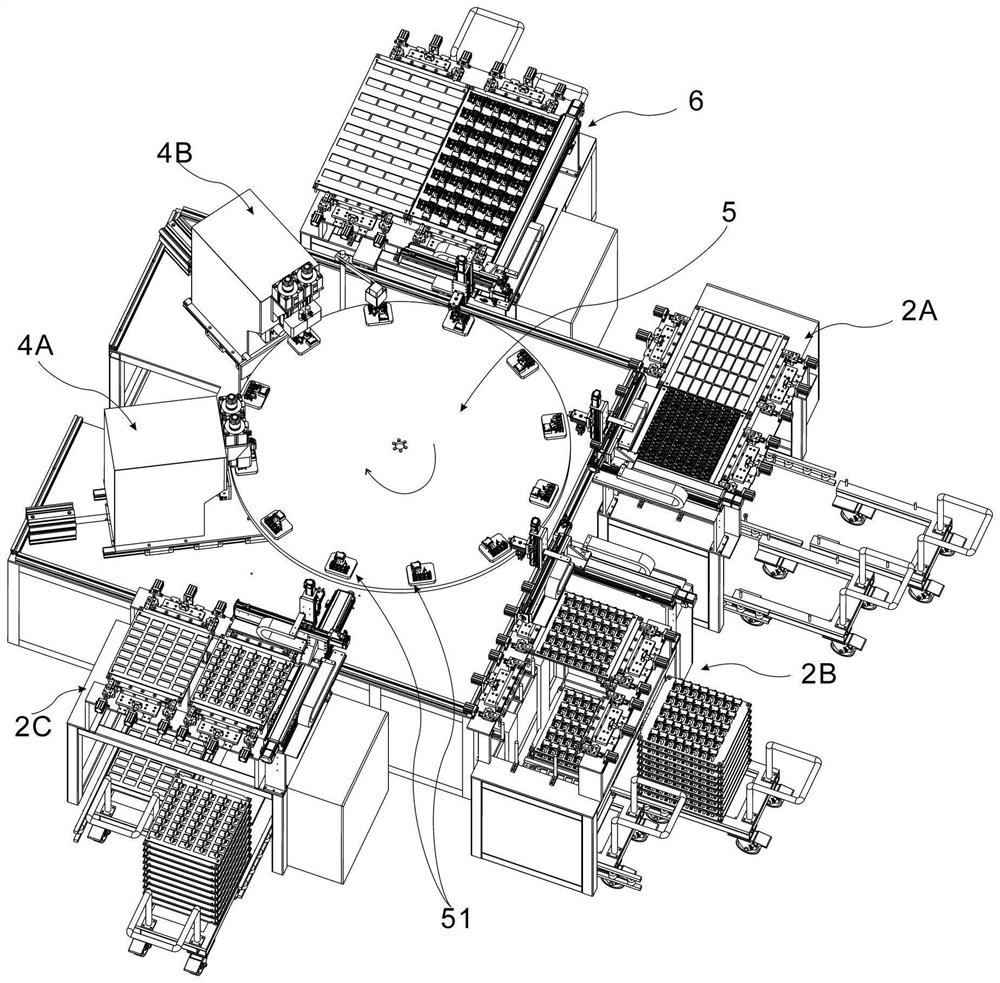

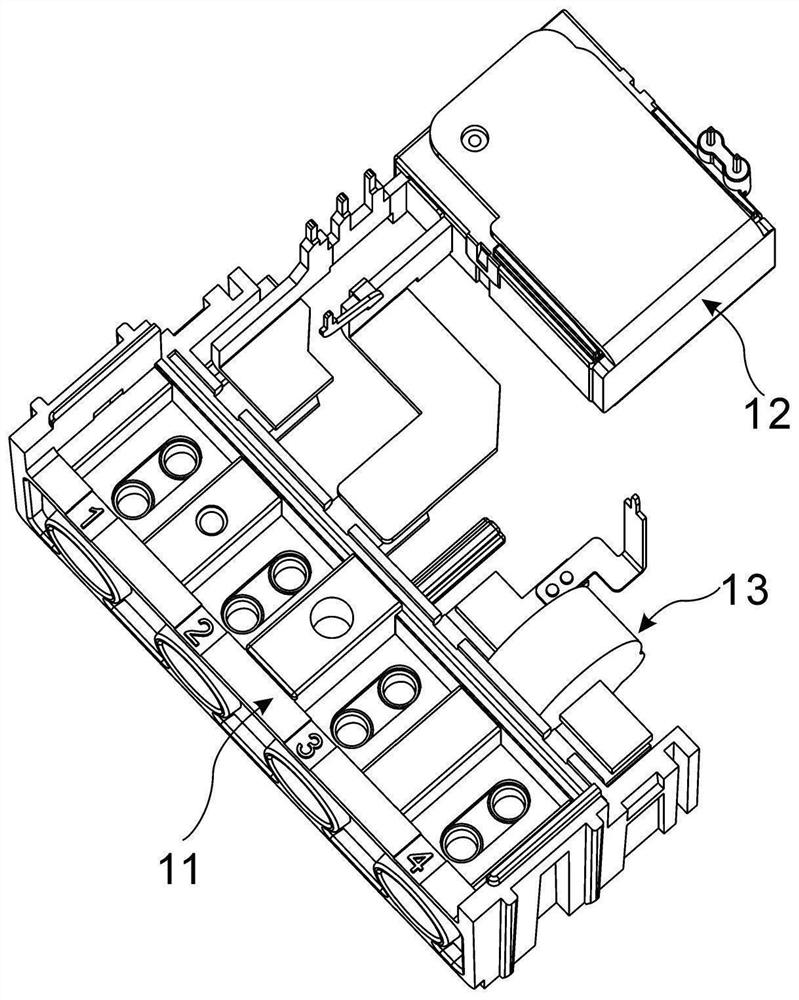

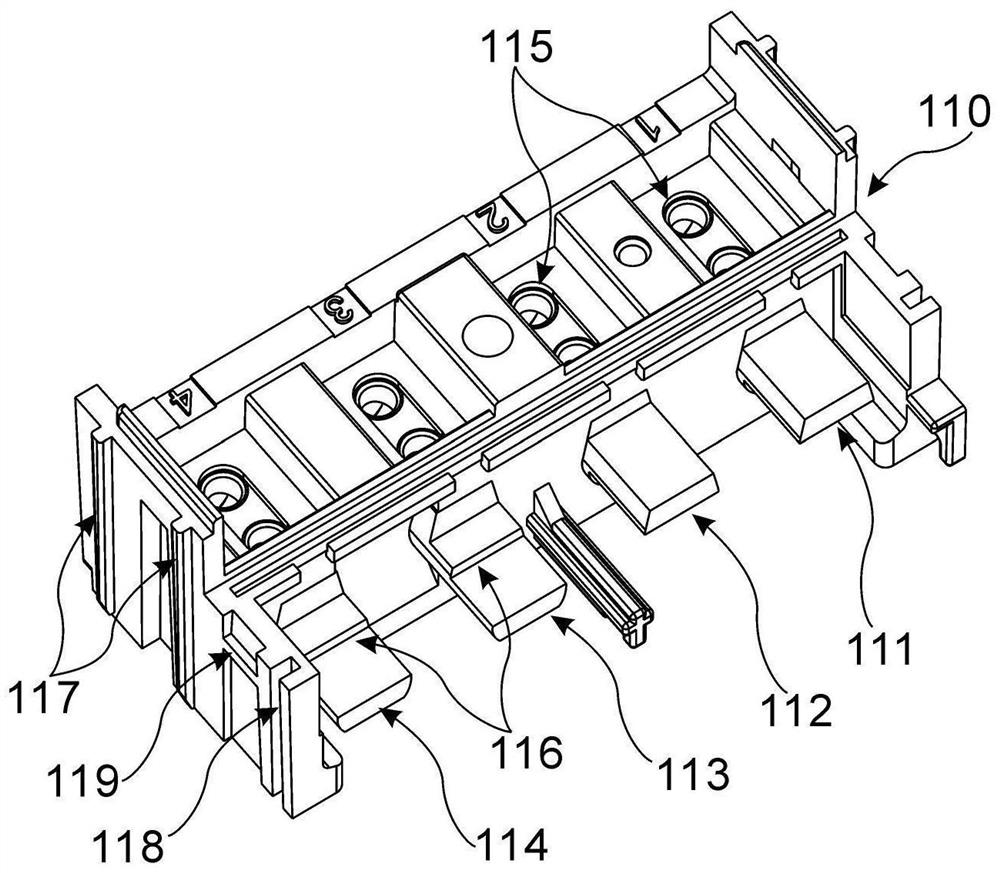

[0041] refer to figure 1 An automatic welding machine for end button boxes, including an indexing turntable 5, three feeding mechanisms 2, two welding mechanisms 4, and a discharging mechanism 6, and the center of the indexing turntable 5 is arranged with a rotating shaft, a turntable motor and a speed reducer. Under the control of the rotating shaft, reducer, turntable motor and controller, the indexing turntable 5 rotates in a step-by-step manner, and twelve fixtures 51 are arranged in a central array on the indexing turntable 5 at equal intervals. The fixture 51 is used to accommodate and limit the workpiece, and transfer the current fixture 51 and the workpiece to the next station by means of the step-by-step rotation of the indexing turntable 5;

[0042] When looking from top to bottom, the indexing turntable 5 rotates step by step in the clockwise direction, wherein the feeding mechanism 2A, the feeding mechanism 2B, the feeding mechanism 2C, the welding mechanism 4A, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com