Full-automatic sand core dip-coating system and dip-coating method thereof

A fully automatic, sand core technology, applied in casting and molding equipment, metal processing equipment, manufacturing tools, etc., to achieve uniform Baume degree, improve quality, and reduce cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

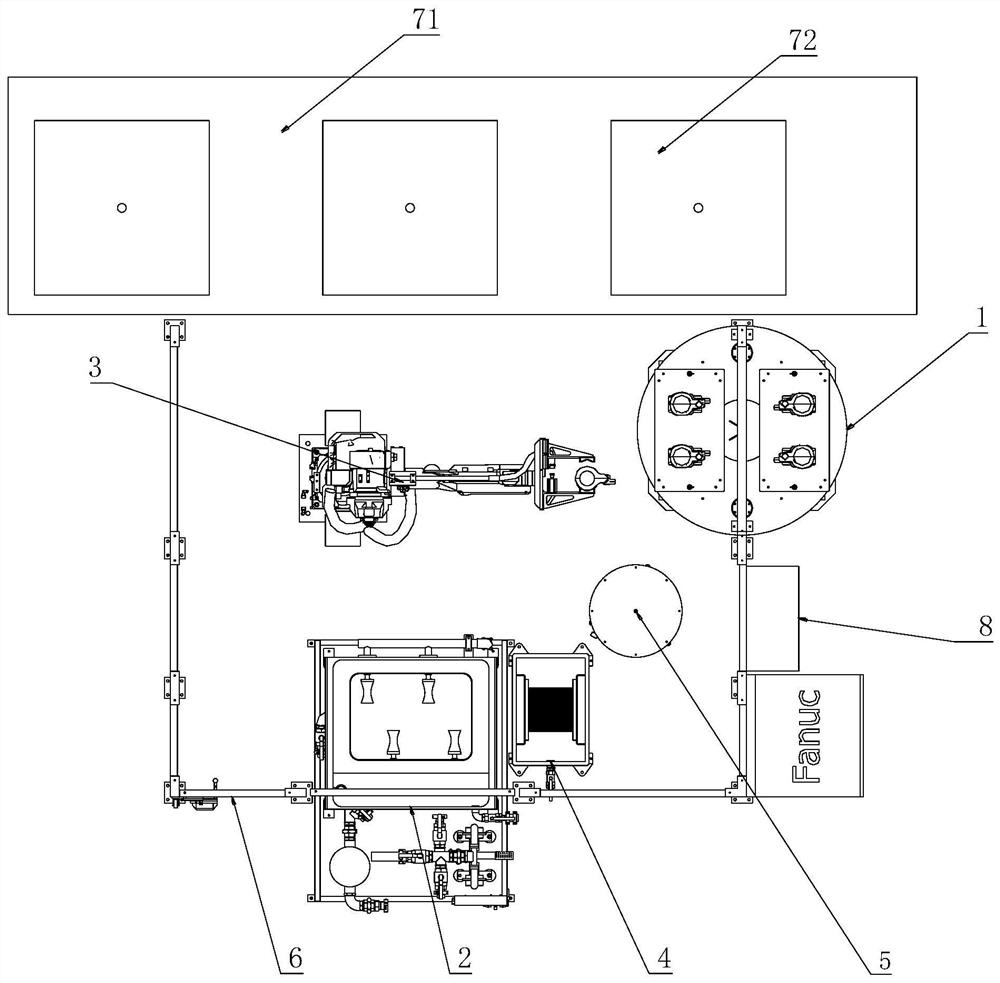

[0046] The fully automatic sand core dip coating system is started by the control system 8. The fully automatic sand core dip coating system includes a feeding unit 1, a dip coating unit 2, a clamping unit 3, a cleaning unit 4, a purging unit 5 and electrical connections with each unit. Sexually connected control system8.

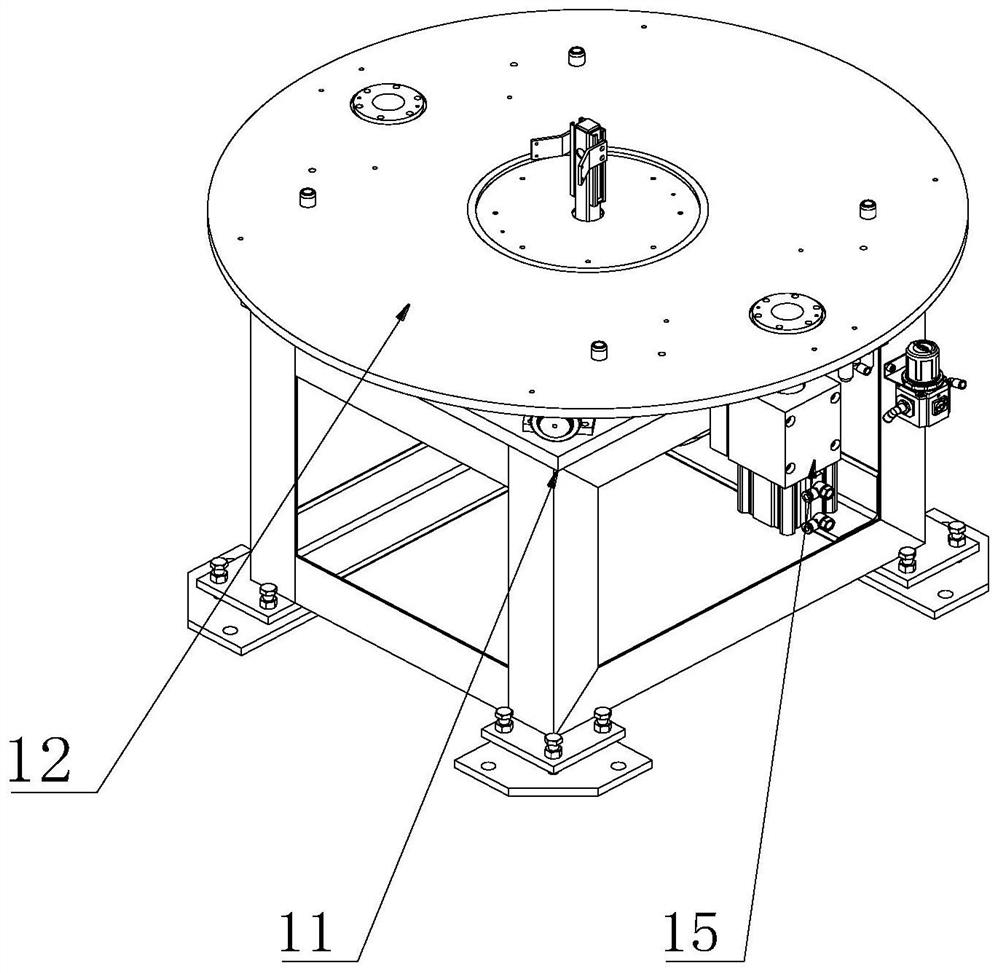

[0047] First, the sand core 9 blank is provided by the feeding unit 1, and the operator places the sand core 9 on the double-station rotary table outside the safety fence 626. The feeding unit 1 includes a base 11, a double-station turntable 12, and a first driving mechanism. 13. The supporting bearing 14 and the positioning mechanism 15, the double-station turntable 12 is installed on the top of the base 11 and its top surface has several sand core 9 molds 121 for placing the sand core 9, and the top surface of the sand core 9 mold 121 has Positioning block 122, a support bearing 14 is provided at the bottom of the double-station turntable and is rotatably...

Embodiment 2

[0052] Embodiment 2: The difference from Embodiment 1 is that in order to facilitate the clamping of sand cores 9 of different specifications, the fixture 32 and the robot 31 can be detachably connected, and can be connected by screws, clamping and locking. The robot 31 includes a robot Main body 311, base 312 and electric control system 313, robot main body 311 is installed on the base 312, and its connection of the two can be motor, gear drive its rotation, electric control system 313 and robot main body 311 and control system 8 are electrically balanced. connect.

Embodiment 3

[0053] Embodiment 3: Different from Embodiment 1, the present invention also includes a safety fence 626 for overall mechanical external protection and a transfer roller assembly 71 for circulating the sand core 9 after spin coating, on one side of the double-station turntable 12 Located in the safety fence and the other side outside the safety fence, the transfer roller assembly 71 is arranged on one side of the robot 31, in detail, the safety fence 626 includes a column 61, a fence 62, a safety door 63 and a door lock 64, and the column 61 is provided with Several, the fence 62 is provided with several leaves and is installed on the column 61, and each fence 62 encloses the whole mechanical device in the system frame, and one of the fences 62 is provided with a safety door 63, and a door lock 64 is installed on the safety door 63, and the door lock 64 is connected with the control system 8, once the safety door 63 is opened, the machine.

[0054] A fully automatic sand core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com