Mixing device for breeding

A mixing device and mixing technology, applied in the field of breeding, can solve the problems of insufficient mixing, affecting the service life of the motor, and insufficiently uniform growth of livestock, and achieve the effects of reducing the rotating force, increasing the uniformity, and fully mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

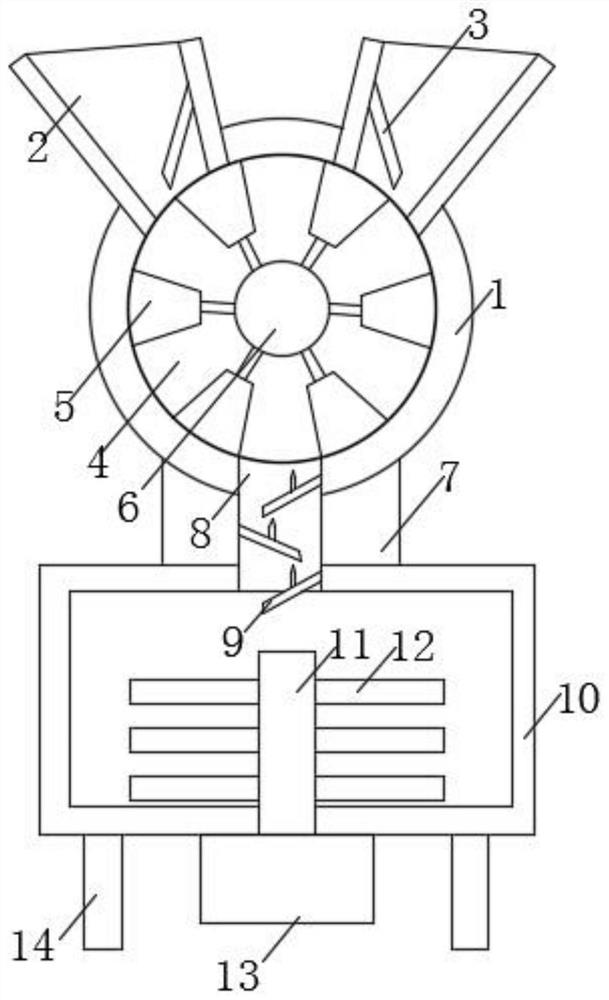

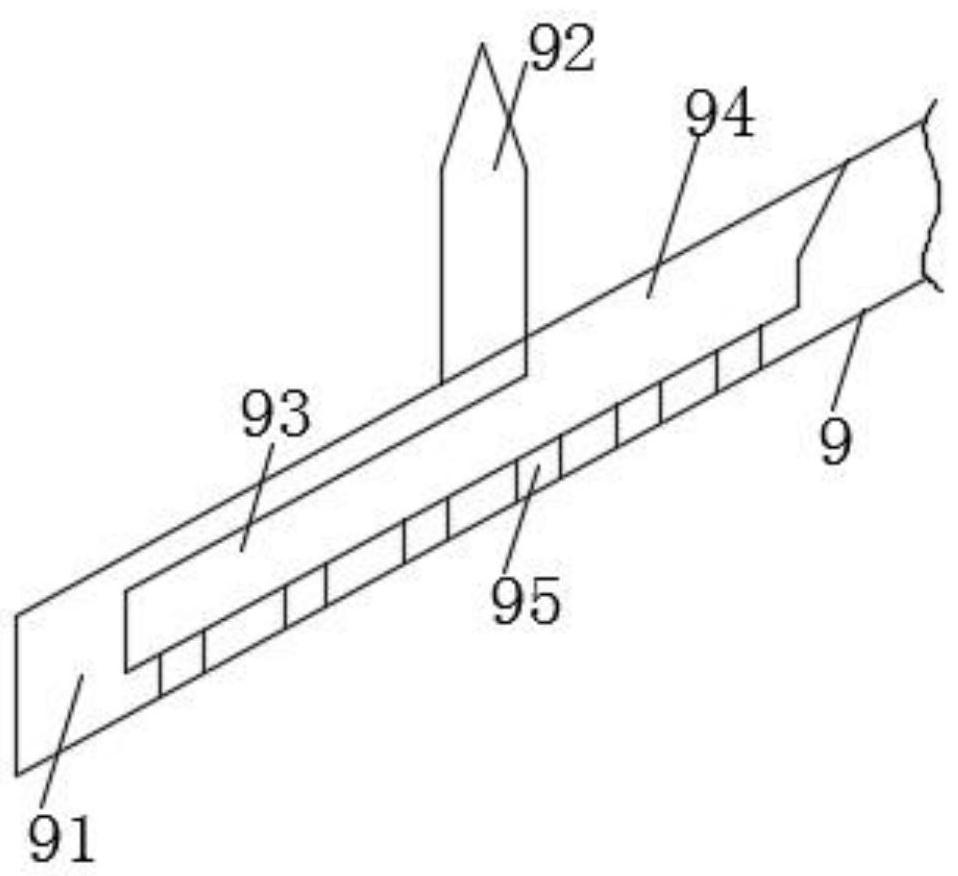

[0017] see Figure 1-2 , the present invention provides a technical solution: a mixing device for breeding, including a first mixing shell 1, the upper end of the first mixing shell 1 is fixedly connected with feeding chambers 2 on the left and right sides, and the mixing The ingredients are put into the feeding chamber 2, and the inner cavity of the feeding chamber 2 is fixedly connected with a baffle plate 3. In order to limit the amount of the material in the feeding chamber 2 entering the trapezoidal groove 5, the baffle plate 3 is 60° away from the horizontal plane. degree to 65 degrees, the surface of the baffle 3 is smooth. The inner cavity of the first mixing housing 1 is movably connected with a rotating roller 4, which also plays a certain mixing role in order to transfer the material in the feeding chamber 2, and the outer side of the rotating roller 4 is provided with a trapezoidal Groove 5, trapezoidal groove 5 In order to have the mixed material, the middle part...

Embodiment 2

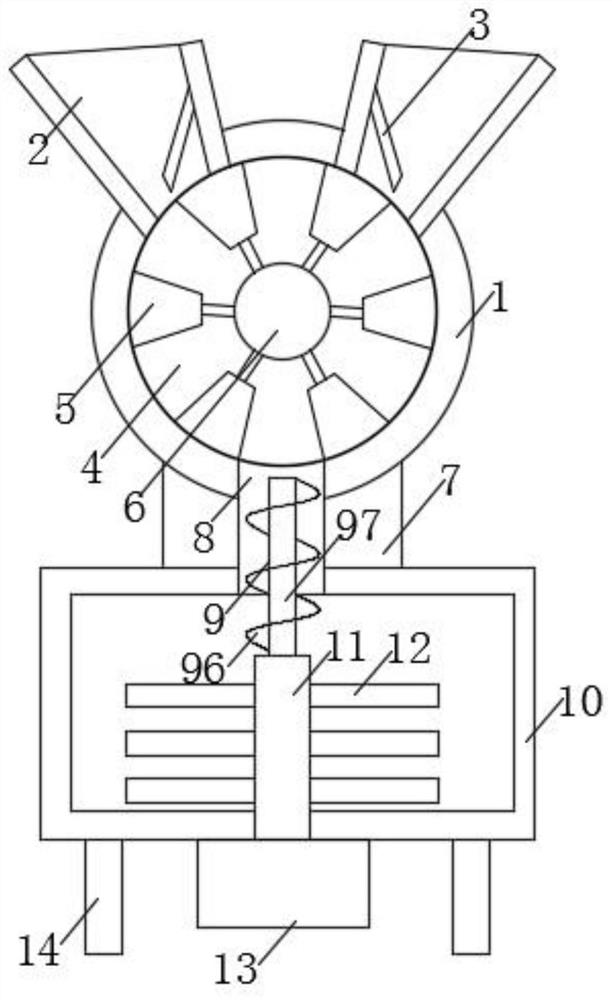

[0020] see image 3 The present invention provides a technical solution: a reduction shaft 97 is plugged into the middle of the inner cavity of the feeding chamber 8, the lower end of the reduction shaft 97 is fixedly connected to the upper end of the transmission rod 11, and the side wall of the reduction shaft 97 A deceleration impeller 96 is wrapped on the top, and the deceleration impeller 96 is helical.

[0021] Working principle: when the material enters the feeding chamber 8, the motor 13 drives the transmission rod 11 to rotate, so that the decelerating shaft 97 and the decelerating impeller 96 rotate, which can make the material falling from the feeding chamber 8 turn over and fall, making the mixing of materials more efficient. full.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com