Power cable connector and connecting method thereof

A power cable and connector technology, which is applied in the field of power cable connectors and their connections, can solve problems such as cable looseness, overheating of cable connectors, and fires, and achieve the effects of preventing cable loosening, facilitating wiring, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

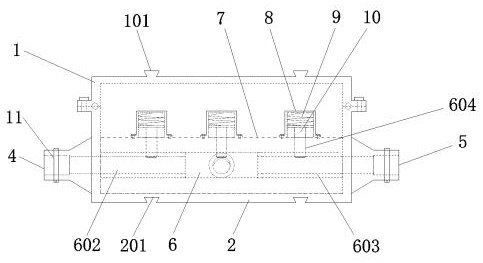

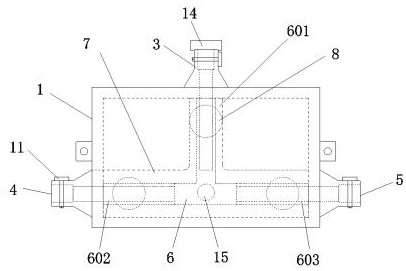

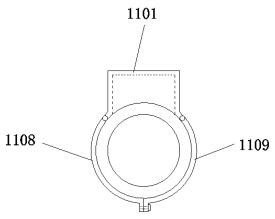

[0029] A power cable connector such as Figure 1 to Figure 2 As shown, it includes a housing, a wiring module and a crimping module, the wiring module is installed inside the housing, and the crimping module is installed on the wiring module; the housing includes an upper housing 1 and a lower housing 2, The upper casing 1 is connected with the lower casing 2 by bolts; the front side wall of the lower casing 2 is provided with an upper wire inlet 3, the left side of the lower casing 2 is provided with a left wire inlet 4, and the right side of the lower casing 2 A right wire inlet 5 is provided; the wiring module includes a terminal 6, the terminal 6 is covered with a sheath 7, and the terminal 6 includes an upper terminal 601, a left terminal 602 and a right terminal 603, and the upper terminal 601 Connected with the upper wire inlet 3, the left wire inlet 602 is connected with the left wire inlet 4, and the right wire inlet 603 is connected with the right wire inlet 5; The ...

Embodiment 2

[0036] A power cable connector such as figure 1 As shown, the top surface of the upper housing 1 is provided with a pin 101, and the bottom surface of the lower housing 2 is provided with a slot 201, which can realize the splicing of multiple cable connectors, ensure the neatness of the wiring, and facilitate the heat dissipation of the cables.

[0037]It can further be that semi-circular grooves are provided on the upper and lower contact surfaces of the upper housing 1 and the lower housing 2, and the two semi-circular grooves form a circular groove, and a sealing ring is installed in the circular groove to play a better sealing effect. , to achieve waterproof function.

[0038] It can be further, such as Figure 4 As shown, the side walls of the upper wire inlet 3, the left wire inlet 4 and the right wire inlet 5 are respectively provided with a sliding groove 12 and a locking hole 13, and a locking clip 11 is installed on the sliding groove 12 and the locking hole 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com