Wheel tread defect three-dimensional detection method and system

A technology for wheel tread and three-dimensional detection, applied in image data processing, instrumentation, calculation, etc., can solve problems such as low reliability of detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

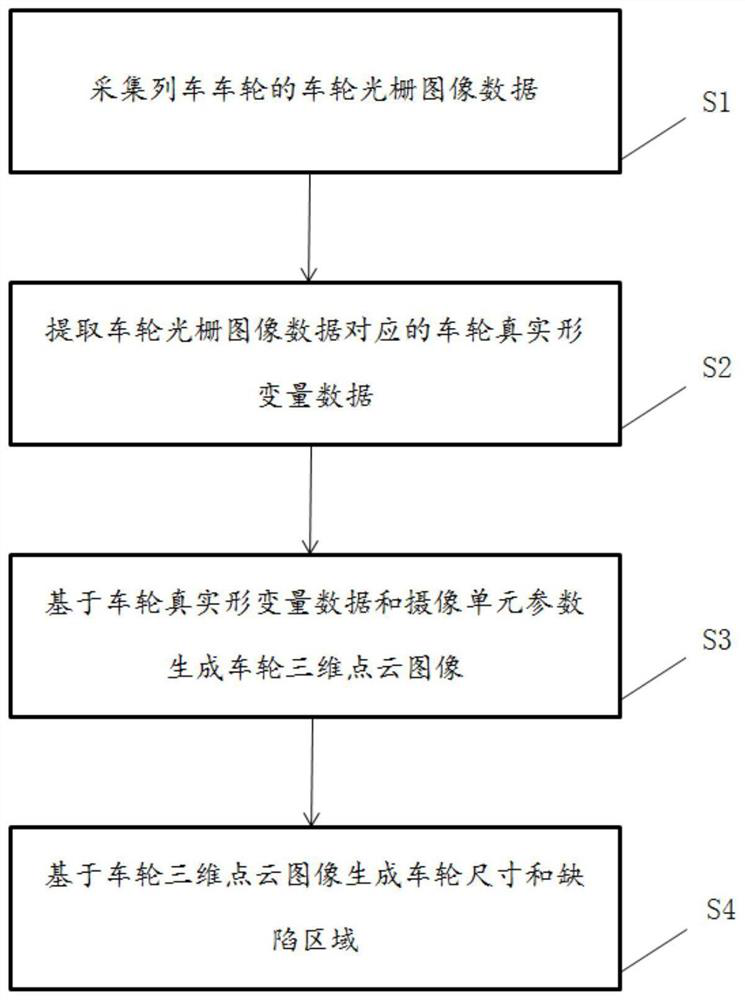

[0023] like figure 1 As shown, a three-dimensional detection method for wheel tread defects, including:

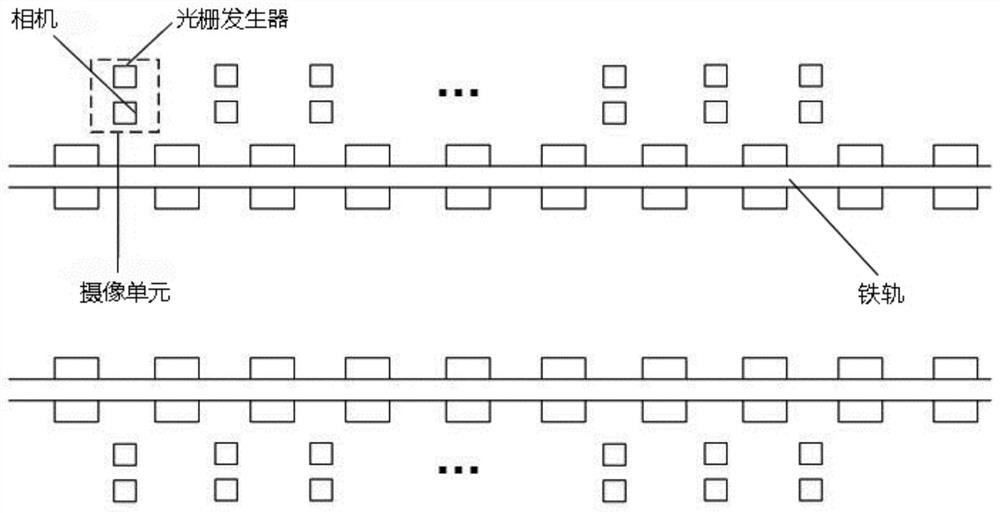

[0024] S1: if Figure 4 As shown, the wheel raster image data of the train wheel is collected.

[0025] S2: Extract the real wheel deformation data corresponding to the wheel raster image data.

[0026] Further, the S2 includes: obtaining a data set composed of multiple raster photos of train wheels, collecting the real deformation of the train wheels corresponding to each of the raster photos, and analyzing the grating deformation area of each of the raster photos Marking, constructing the mapping relationship between the grating deformation region of each grating photo and the real deformation of the train whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com