Multi-mass point series speed amplification vibration damping device and connection method for wind power blades

A technology of wind power blades and vibration damping devices, which is applied to wind power generation, assembly of wind power engines, and wind power engines consistent with the wind direction. Improve the effect of damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

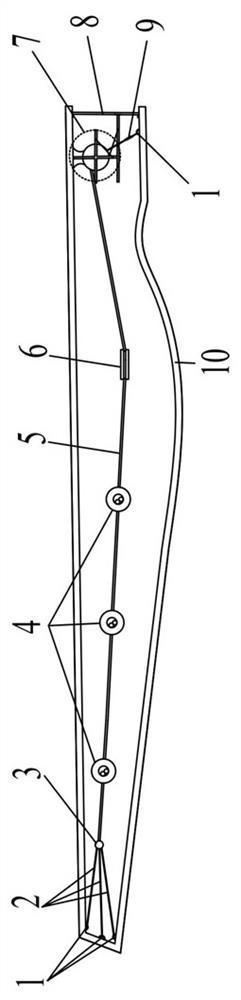

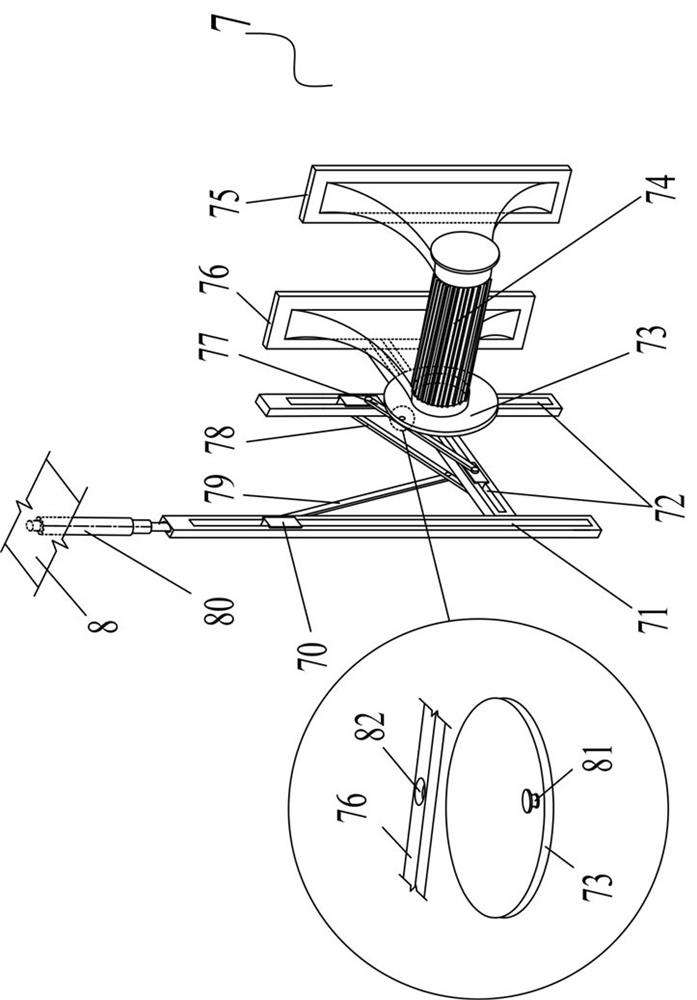

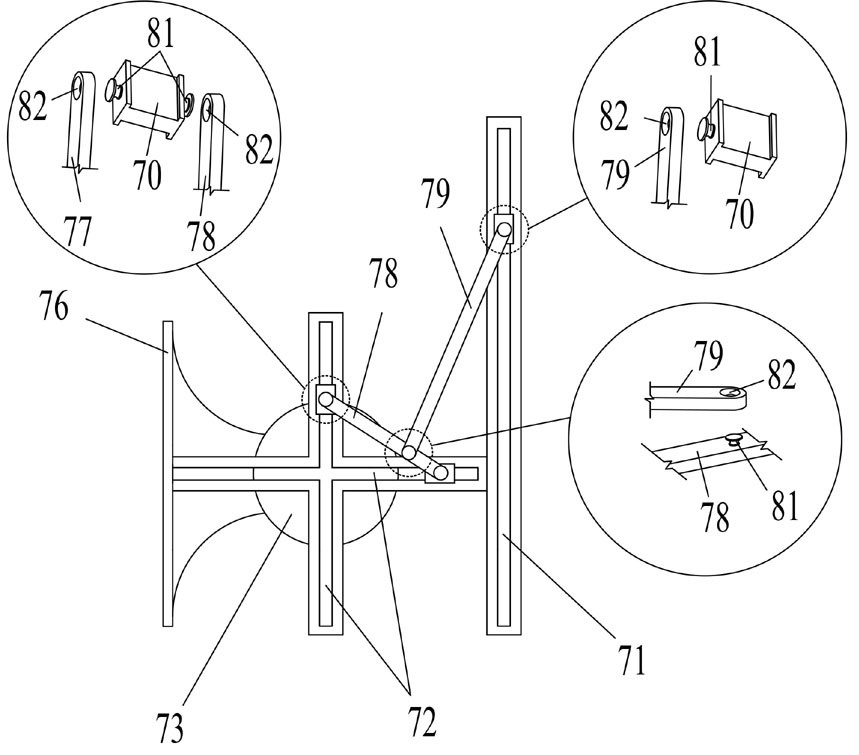

[0021] Such as Figure 1 to Figure 8 As shown, the wind power blade multi-mass series speed amplification damping device of the present invention includes a pull ring 1, a No. 1 steel cable 2, a porous bolt ball joint 3, a hollow mass steel ball 4, a No. 2 steel cable 5, and a fixed pulley device 6. Speed amplification device 7, return spring 9, pull ring 1 with 4 pieces; porous bolt ball joint 3 consists of No. 1 cable screw hole 30, No. 1 cable screw rod 31, No. 2 cable screw hole 32, and The steel cable screw 33 is composed of the No. 1 steel cable screw hole 30 and the No. 1 steel cable screw 31, and the No. 2 steel cable screw hole 32 is connected with the No. 2 steel cable screw 33 to form a porous bolt ball joint 3; the fixed pulley device 6 There is one, consisting of two symmetrical and tangent fixed pulleys 61 anchored on the fixed plate 63 through the flange shaft 60 and the fixed nut 62; the speed amplifying device 7 consists of No. 1 support 75, No. 2 support 76...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com