Automatic discharging mechanism for stringed pagoda tubes

A technology of automatic discharge and pagoda tube, applied in the direction of labeling machine, conveyor objects, labels, etc., can solve the problems of excessive paper scraps, falling off, waste, etc., achieving small footprint and space, high automation level, Movement light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

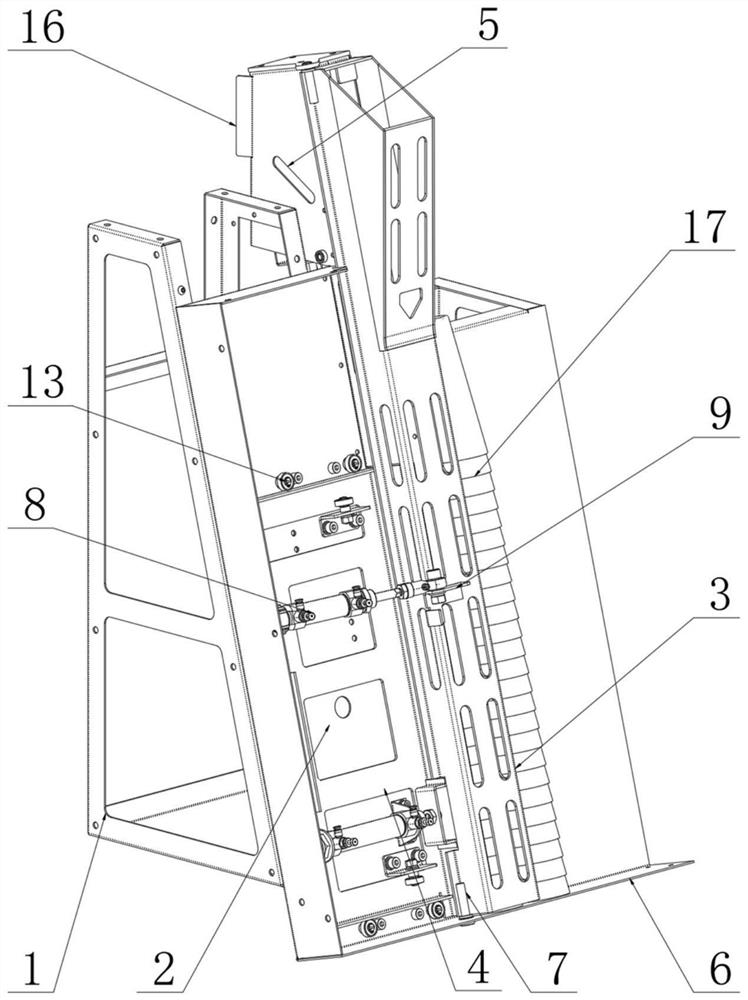

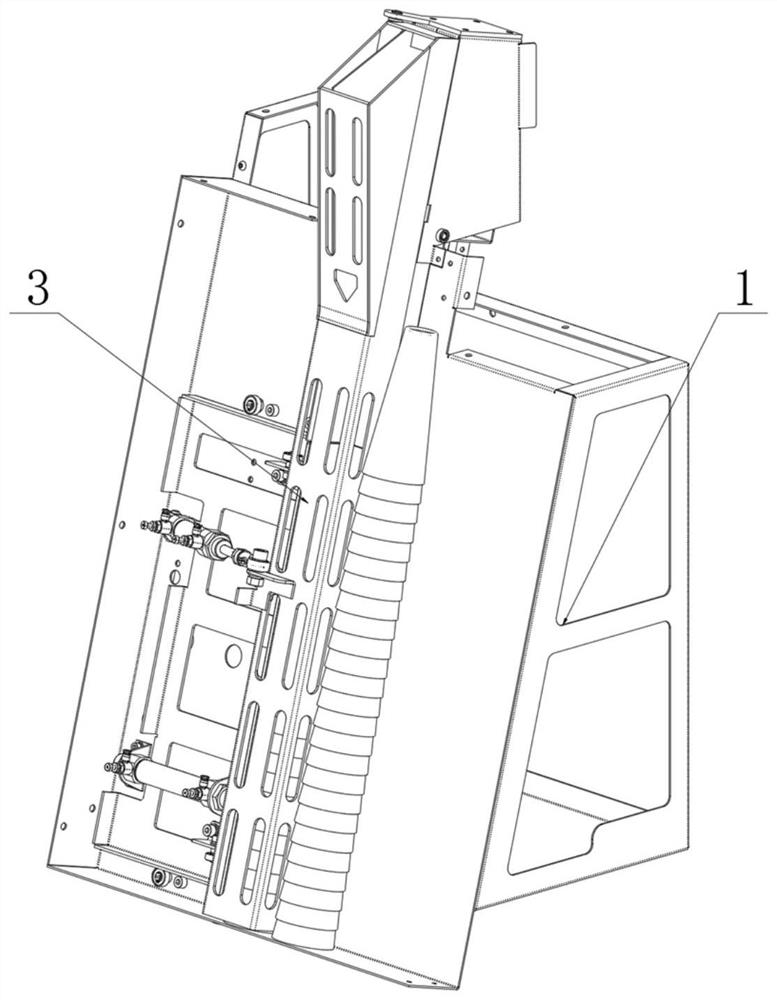

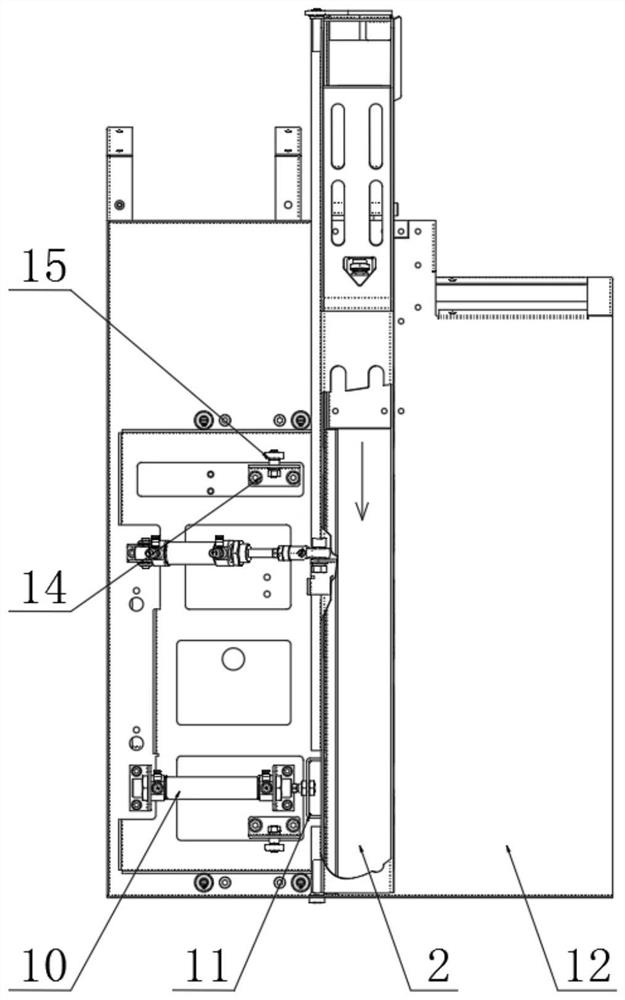

[0058] see Figure 1 to Figure 9 , the present invention relates to a series of pagoda pipe automatic discharge mechanism, which includes a bracket 1, the front side of the bracket 1 is provided with a guide slant plate 2, and the front side of the guide slant plate 2 is provided with a guide slide that can be opened and closed. The channel groove 3 and the pusher plate 4 that can be pushed horizontally left and right, and the pusher plate 4 can push out the stringed pagoda tubes after the guide slideway groove 3 is opened;

[0059] The guide chute groove 3 can be flipped and opened as a whole or a door 18 is arranged on the discharge side of the guide chute groove 3, and the door 18 adopts the mode of rotating the rotating shaft to open the door or pushing and pulling the door back and forth;

[0060] A guide hopper 5 is arranged on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com