Rotary-disc assembly line type automatic assembling and packaging method and equipment for nasal oxygen cannulas

An assembly line, packaging method technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of low automation degree and production efficiency, large impact on production quality, and poor product stability, so as to improve the level of production automation and liberate the labor force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

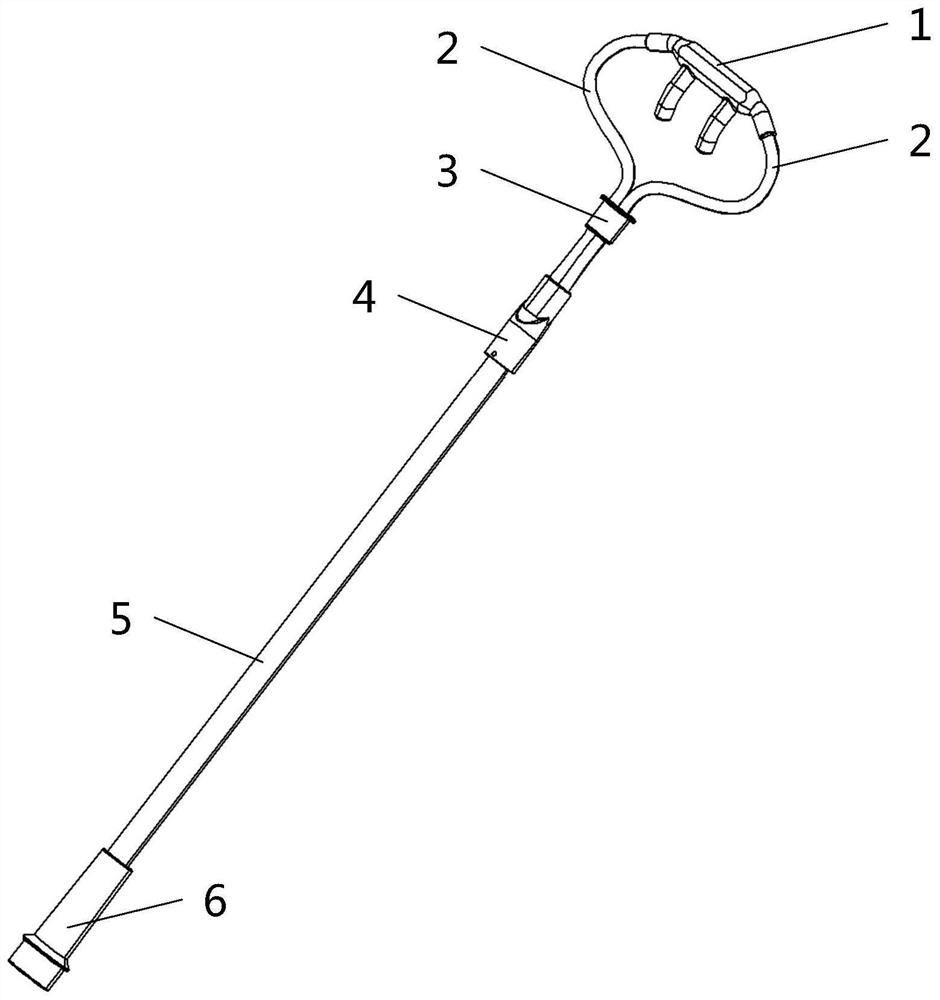

[0060] figure 1 It is a schematic structural diagram of a nasal oxygen tube. The nasal oxygen tube to be assembled and packaged in the turntable assembly line type nasal oxygen tube automatic assembly and packaging method provided by the embodiment of the present invention is as follows: figure 1 As shown, the nasal oxygen tube includes a soft nose tip 1, a nasal catheter 2, an adjustment buckle 3, a tee 4, a connecting catheter 5, and a two-way 6. Among them, the two ends of the soft nose tip 1 are respectively connected with a nasal catheter 2, and the two nasal catheters 2 are connected to the tee 4 through the adjustment buckle 3; the other end of the tee 4 is connected to the connecting catheter 5, and the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com