Railway vehicle and safety handrail thereof

A rail vehicle and safety technology, which is applied in the field of rail vehicles, can solve the problems that cannot meet the requirements of use, and the single-bar handrail cannot meet the requirements of use, so as to achieve the effects of improving passing efficiency, maximizing passing space, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

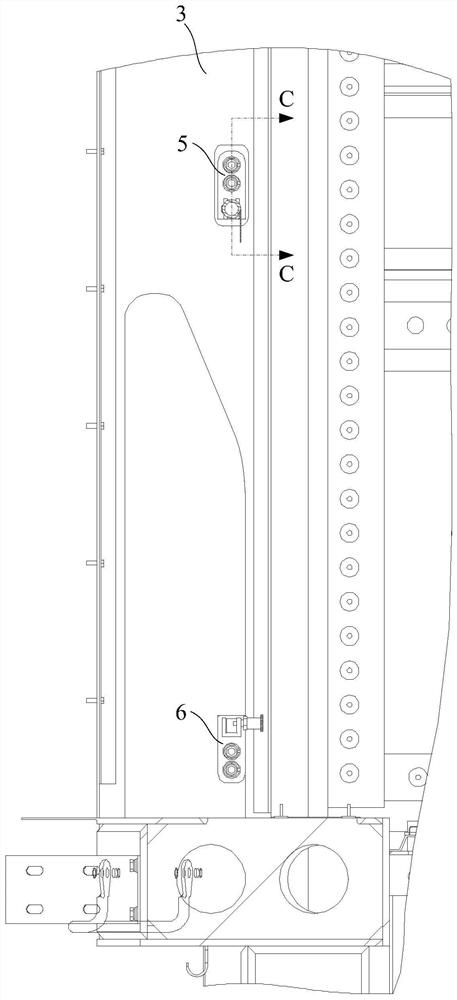

[0058] The embodiment of the present application provides a safety handrail 4 for rail vehicles, such as Figure 6 and Figure 7 As shown in the structure, the safety handrail 4 includes an outer tube 41 and an inner tube 42; wherein:

[0059] The inner tube 42 has a first end and a second end oppositely arranged, the first end is slidably installed in the outer tube 41, and the second end is provided with a locking hole 4251;

[0060] Such as Figure 8 As shown in the structure, the outer tube 41 is fixedly connected with a limit sleeve 411 on the end face facing the inner tube 42, and a hinged joint 412 is detachably installed at the end away from the inner tube 42. The limit sleeve 411 is used to connect the first end of the inner tube 42 One end is limited in the outer tube 41;

[0061] The outer peripheral surface of the outer tube 41 is covered with a warning sign 43 that can rotate around the axis of the outer tube 41 .

[0062] Because one end of the inner tube 42 ...

Embodiment 2

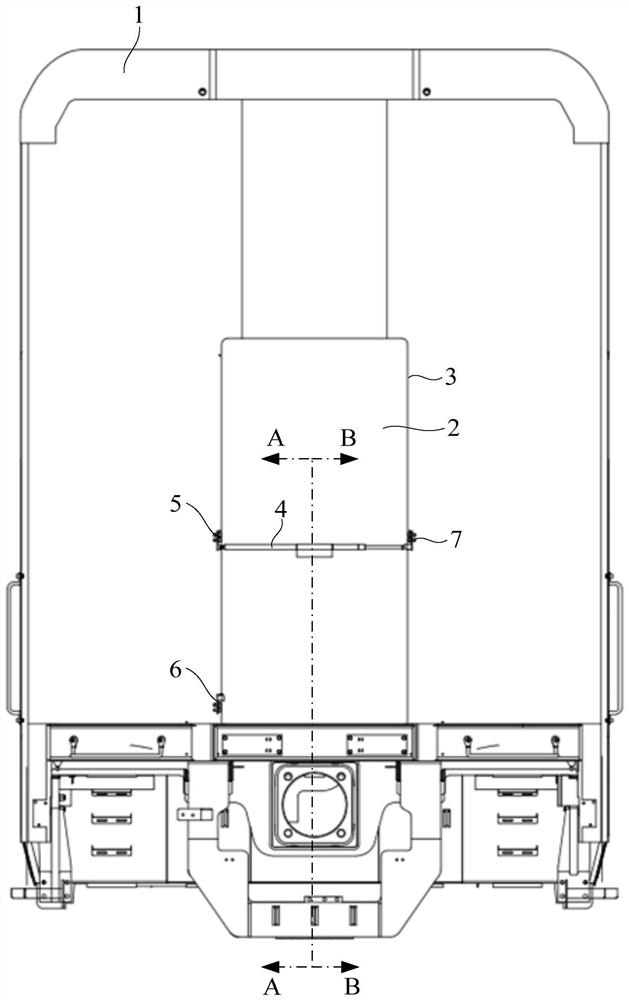

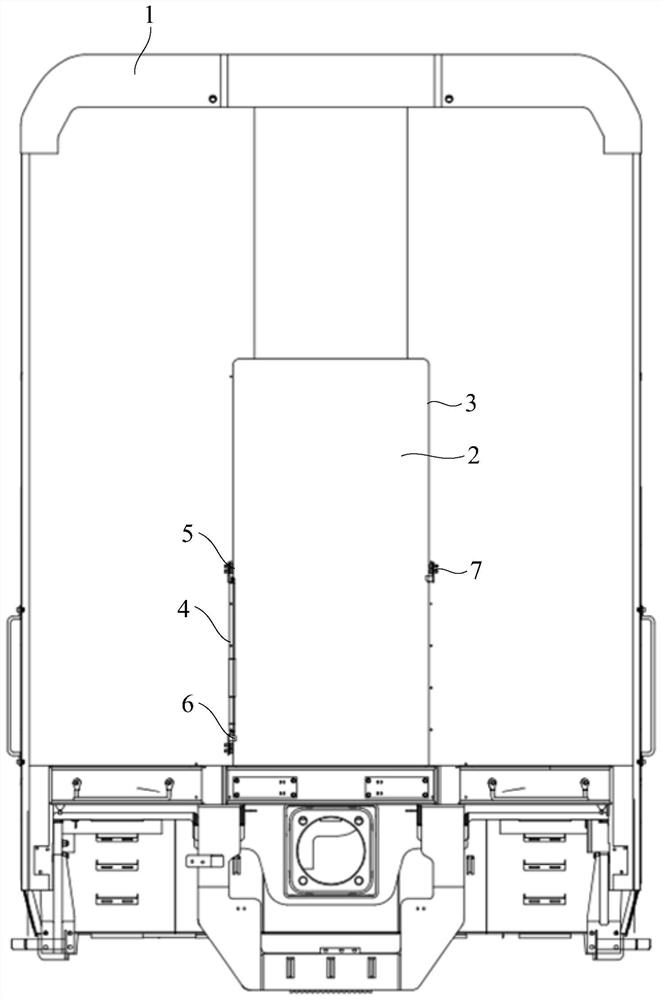

[0077] The embodiment of the present application also provides a rail vehicle, such as figure 1 and figure 2 As shown in the structure, the rail vehicle includes a car body 1. The car body 1 is provided with a door column 3 forming a passage door 2, and also includes a mounting seat fixed on the door column 3 and any safety handrail provided by the above-mentioned embodiments. 4; The schematic diagram of the use status of the safety handrail 4 during work can be referred to figure 1 , and the structural schematic diagram when the safety handrail 4 is in retracted state can refer to figure 2 The mounting base includes an outer tube mounting base 5, a first inner tube mounting base 6 and a second inner tube mounting base 7 coplanarly arranged, wherein the outer tube mounting base 5 is vertically opposite to the first inner tube mounting base 6 Setting, the outer tube mounting seat 5 and the second inner tube mounting seat 7 are relatively arranged along the horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com