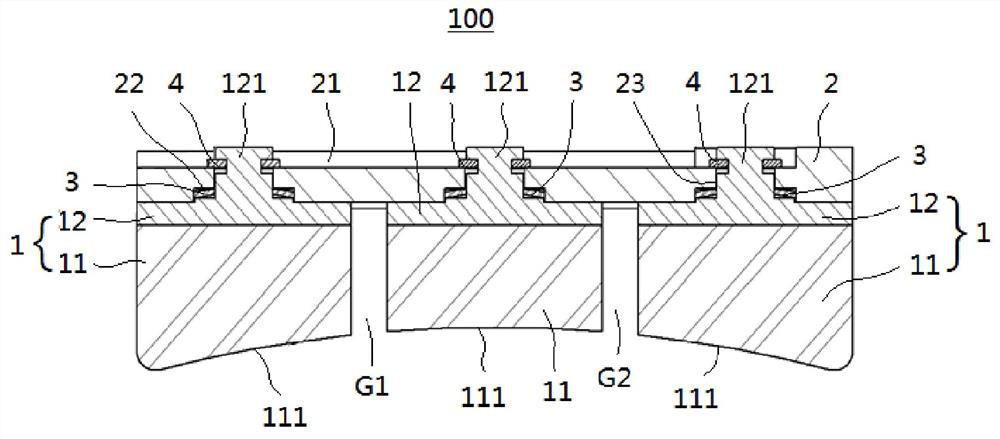

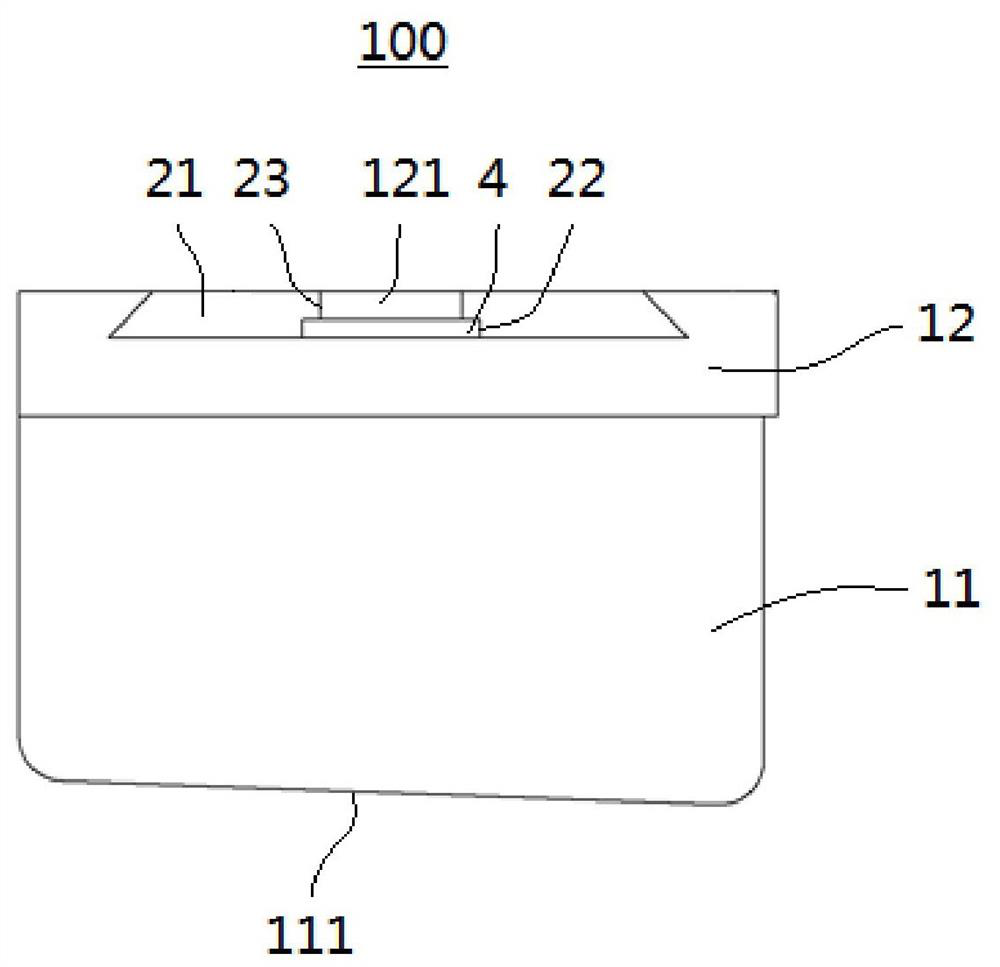

Split type grinder, wheel tread cleaning device of railway vehicle, and railway vehicle

A technology for rail vehicles and wheel treads, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of wear debris adhering to the wheel surface, reducing surface hardness, scratching the wheel tread, etc., to reduce scratches. Probability of wheels, reduction of frictional vibration, use of flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] First of all, it should be noted that the composition, working principle, characteristics and advantages of the split grinder, the wheel tread cleaning device for rail vehicles and rail vehicles according to the present invention will be described below by way of example, but it should be understood that Yes, all descriptions are given for the purpose of illustration only, and therefore should not be construed as forming any limitation on the present invention. Herein, the technical term "connect" and its derivatives cover that one component is directly connected to another component and / or indirectly connected to another component.

[0022] In addition, for any single technical feature described or implied in the embodiments mentioned herein, or any single technical feature shown or implied in the drawings, the present invention still allows and their equivalents) without any technical barriers, thereby obtaining more other embodiments of the present invention that may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com