Residual material recycling device for building material production

A technology for recycling devices and building materials, applied in the field of residual material recycling devices for the production of building materials, can solve the problems of increased transportation and loss costs, impact on economic benefits, waste of debris, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

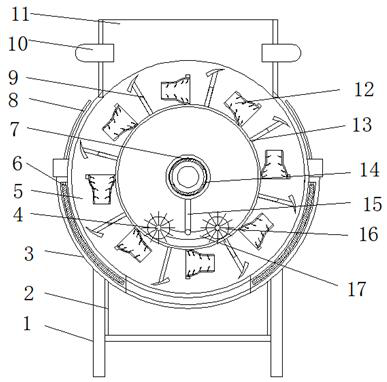

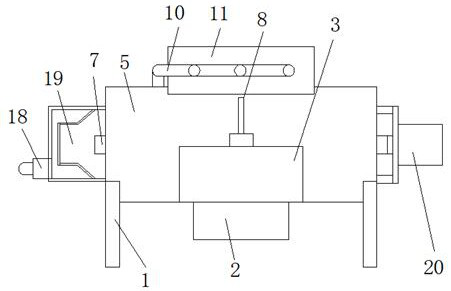

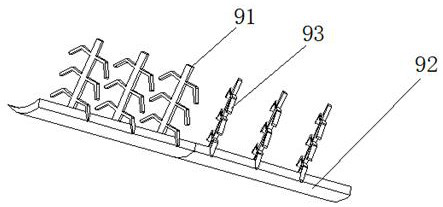

[0025] refer to Figure 1-4 , a residual material recovery device for building material production, comprising a machine base 1, a housing 5 is fixedly installed on the top of the machine base 1, and a feed hopper 11 is fixedly installed on the top of the housing 5, and a bottom end of the housing 5 is fixed The discharge box 2 is installed, and the end of the housing 5 is fixedly equipped with a filter 19, and the side top of the filter 19 is fixedly installed with a transfer pump 18, and the outlet end of the transfer pump 18 is connected to the both sides of the feed hopper 11. A circulation pipe 10 is fixedly installed between them, and the inside of the housing 1 is installed with a support pipe body 7 through bearings, and the end of the support pipe body 7 extends to the inside of the filter 19, and both sides of the support pipe body 7 are provided with flow grooves 14, and the outer side of support pipe body 7 is fixedly installed with recovery net cylinder 13, and th...

Embodiment 2

[0033] refer to Figure 1-5 , a kind of residue recovery device for building material production. Compared with Embodiment 1, in this embodiment, the outer side of the support pipe body 7 is rotationally connected with two limit rings 15, and the bottom ends of the limit rings 15 are fixedly installed with Connecting rod 17, cleaning rod 4 is all rotatably installed between two connecting rod 17 ends, and the outside of cleaning rod 4 is provided with a plurality of hair posts, and the both ends of cleaning rod 4 are all rotatably equipped with scroll wheel 16.

[0034] When this embodiment is in use, when the support pipe body 7 rotates, it is pulled by gravity, and the connecting rod 17 and the cleaning rod 4 are always located below the interior of the recovery net cylinder 13, and the cleaning rod 4 follows the rotation during the rotation of the recovery net cylinder 13. , the hair pillars on its surface are inserted into the mesh interior of the recovery net cylinder 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com