Coffee heat treatment solution, coffee extracting solution, preparation method of coffee extracting solution and applications of coffee heat treatment solution and coffee extracting solution

A coffee extraction and thermal reaction technology, applied in coffee extraction, green coffee processing, etc., can solve the problems of weakened aroma concentration, intolerant of coffee beans storage, loss of aroma substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the present invention provides a method for preparing a coffee extract, comprising the following steps:

[0026] Pulverizing green coffee beans to prepare green coffee bean powder;

[0027] Dissolving the green coffee bean powder in an organic solvent for thermal reaction, filtering to prepare filter residue and heat treatment liquid, the temperature of the thermal reaction is 100°C-250°C, and the reaction time is 1h-5h;

[0028] Add ethanol solution to the filter residue, heat and reflux extraction to prepare coffee extract, the mass ratio of the filter residue to the ethanol solution is 1:2 to 1:8, and the concentration of the ethanol solution is 50 (v / v) % to 95 (v / v)%, the heating and reflux temperature is 70°C to 80°C, the number of extractions is 1 to 2 times, and the time for each extraction is 2h to 3h.

[0029] The invention uses green coffee beans as raw materials and organic solvents as heating protection medium for thermal reaction, thereby we...

Embodiment 1

[0055] The preparation of embodiment 1 coffee extract

[0056] (1) Take Vietnam Robusta washed and polished G1 green coffee beans, screen and remove defective beans, then crush the screened green coffee beans and pass through a 20-mesh sieve;

[0057] (2) Take 60 g of the crushed green coffee bean powder, add 240 g of glycerin as a solvent to the green coffee bean powder, mix well, stir and heat to 120 ° C for 2 hours of thermal reaction, then filter to obtain 68 g of filter residue and heat treatment liquid ;

[0058] (3) Add 240 g of ethanol with a concentration of 80 (v / v)% to the above filter residue, mix well, stir and heat, reflux extraction once at 78° C., extract for 2 hours, and filter to obtain coffee extract;

[0059] (4) Using a rotary evaporator at a water bath temperature of 60° C. and a pressure of 1200 Pa to rotate the coffee extract to obtain a concentrated coffee extract, and realize the recovery of ethanol from the extract.

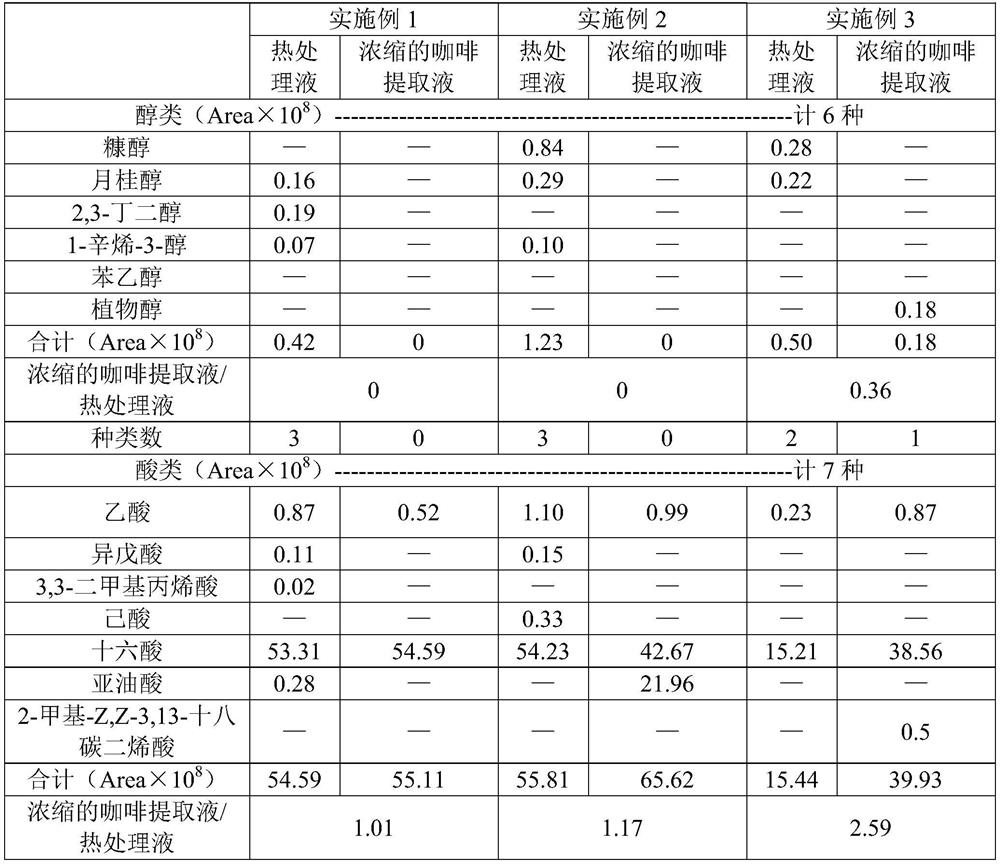

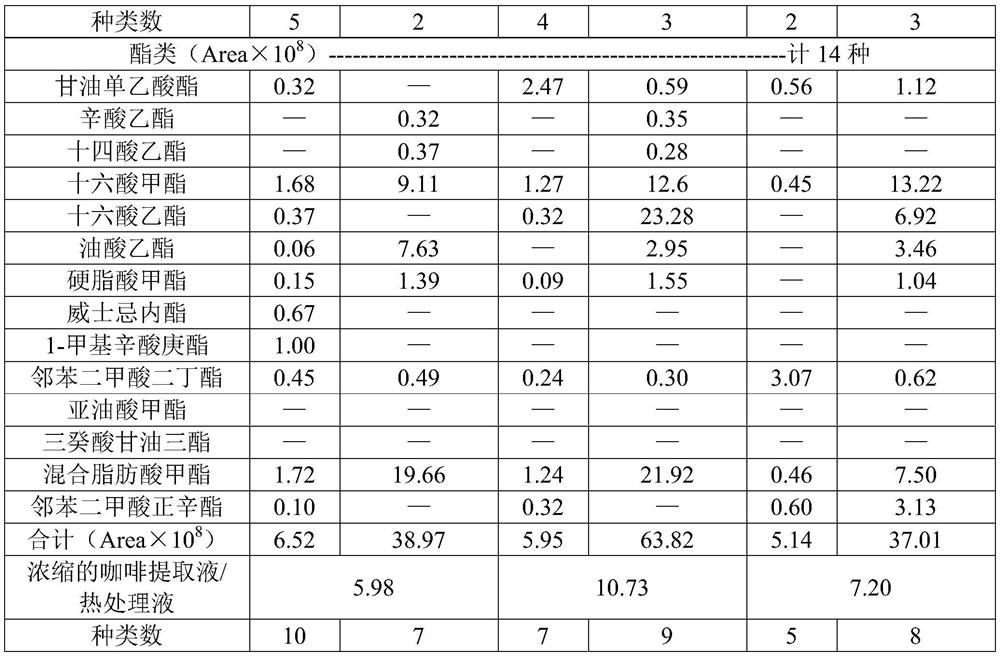

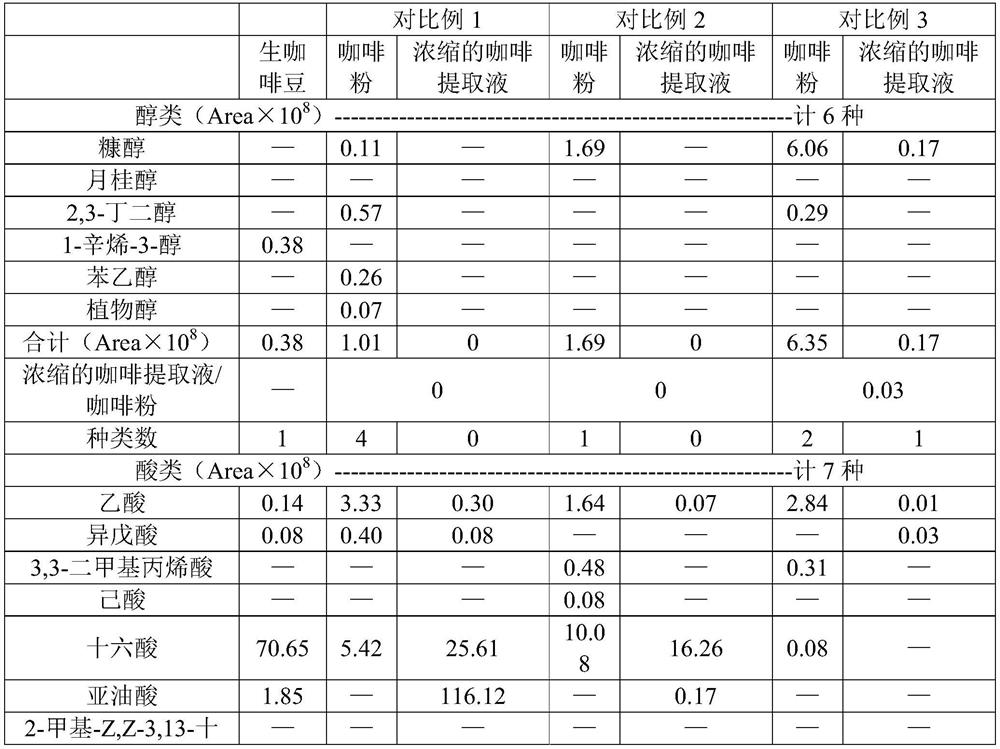

[0060] The compositional analy...

Embodiment 2

[0061] The preparation of embodiment 2 coffee extract

[0062] (1) Take Vietnam Robusta washed and polished G1 green coffee beans, screen and remove defective beans, then crush the screened green coffee beans and pass through a 20-mesh sieve;

[0063] (2) Take 60 g of the crushed green coffee bean powder, add 240 g of glycerin as a solvent to the green coffee bean powder, mix well, stir and heat to 150 ° C for 2 hours of thermal reaction, then filter to obtain 69 g of filter residue and heat treatment liquid ;

[0064] (3) Add 240 g of ethanol with a concentration of 80 (v / v)% to the above filter residue, mix well, stir and heat, reflux extraction once at 78° C., extract for 2 hours, and filter to obtain coffee extract;

[0065] (4) Using a rotary evaporator at a water bath temperature of 60° C. and a pressure of 1200 Pa to rotate the coffee extract to obtain a concentrated coffee extract, and realize the recovery of ethanol from the extract.

[0066] The compositional analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com