Process for producing a packaging weld

A technology of flexible packaging and welding area, applied in the field of packaging tubes for packaging liquid or viscous products, and the field of flexible packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

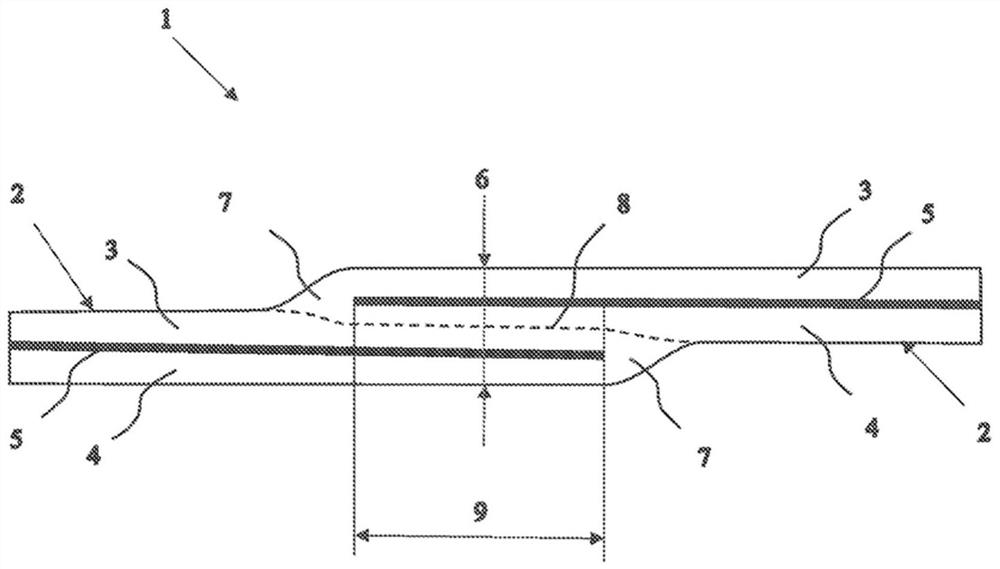

[0136] figure 1 A first example of a weld seam 1 produced by overlapping ends of sheets (eg laminate) in order to produce a package (eg tube) is shown. This weld configuration is generally an example of a weld configuration measured using the procedure according to the invention.

[0137] The ends of the laminate 2 (usually initially flat) are placed one on top of the other to form the overlap 9 . Laminates are generally formed of at least three layers, in this illustrative example of a top layer 3, a bottom layer 4 and a functional layer 5 (as a barrier layer). The measurement referenced as "6" defines the thickness of the weld (to be measured according to the principles of the invention), the reference number "7" shows the cast material after welding, and the reference number "8" indicates the thickness between the ends. Solder interface.

[0138] The weld seam properties of a package have a first-order impact on the strength and tightness of the seal as well as the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com