Train wheel maintenance management system based on digital twinning technology

A train wheel and management system technology, applied in the direction of electrical digital data processing, data processing applications, special data processing applications, etc., can solve the problems of large considerations and scope limitations, large costs, strong dynamic characteristics, etc., and achieve prediction Reliable results, scientific maintenance plan, and the effect of reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

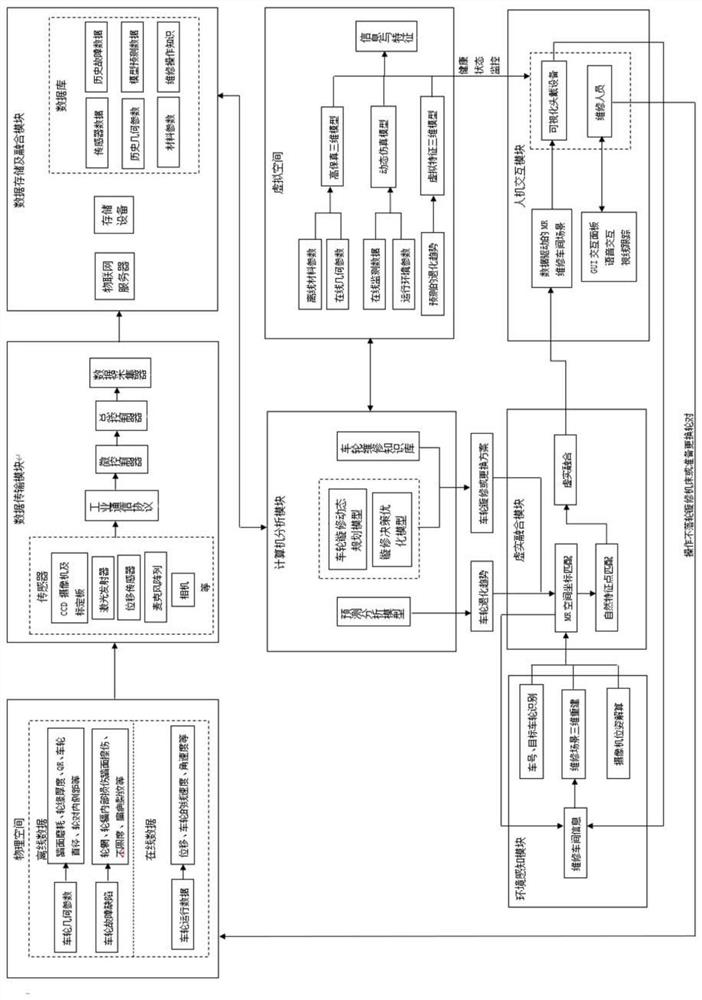

[0032] Such as figure 1 As shown, the present invention provides a train wheel maintenance management system based on digital twin technology, which is used to realize the condition monitoring and maintenance guidance of train wheels, and uses digital twin technology to monitor the health status of train wheels to realize the full life of train wheels cycle management.

[0033]The system includes environmental perception module, virtual-real fusion module, human-computer interaction module, Internet of Things platform and physical space module and virtual space module connected through the Internet of Things platform. The Internet of Things platform includes data transmission module, data fusion and storage module and computer analysis module. The virtual-real fusion module is respectively connected with the environmental perception module and the computer analysis module, and the human-computer interaction module is connected with the virtual space module and the virtual-rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com