Plasma hot-blast stove and gas recycling device based on plasma hot-blast stove

A technology of plasma and gas circulation, applied in the direction of fluid heaters, air heaters, lighting and heating equipment, etc., can solve the problems of low power and temperature, high production costs, large gas restrictions, etc., to achieve multiple choices and low consumption Effect of small, high reactive gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

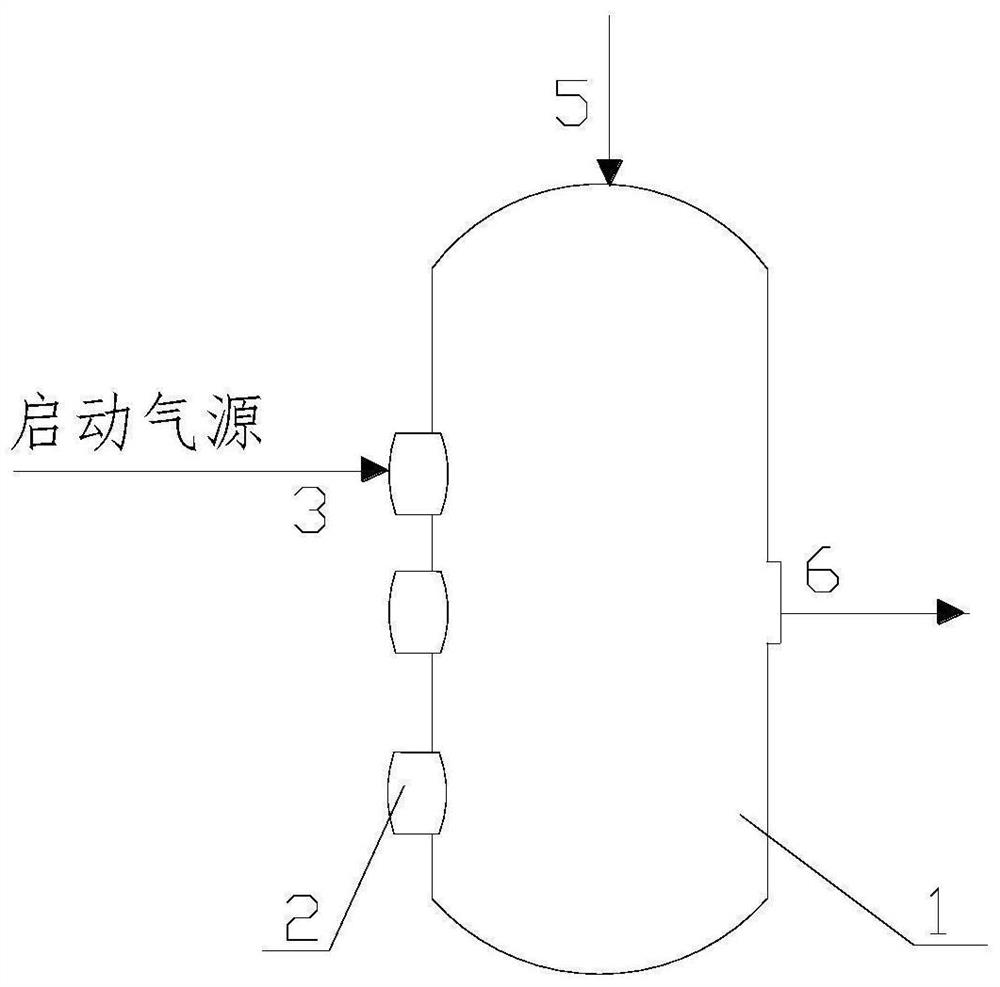

[0026] see figure 1 , the plasma hot blast stove provided in this embodiment includes a furnace body 1 and a plasma generator 2 arranged on the shell of the furnace body 1; Inlet 5 and hot blast gas outlet 6. The inside of the body of furnace 1 is laid with an insulating layer and a refractory layer.

[0027] In this embodiment, there are three plasma generators 2 , which are evenly distributed axially on the shell of the furnace body 2 . One end of the plasma generator 2 is placed in the furnace body 1 to communicate with the inner cavity of the furnace body 1, and the other end of the plasma generator 2 is placed outside the furnace body 1, and is respectively provided with a starting gas source inlet 3. The source inlet 3 communicates with the inside of the furnace body 1, and the plasma generator 2 is also connected with an external power supply.

[0028] In this embodiment, the starting gas source inlet 3 communicates with the starting gas source pipeline. .

[0029]...

Embodiment 2

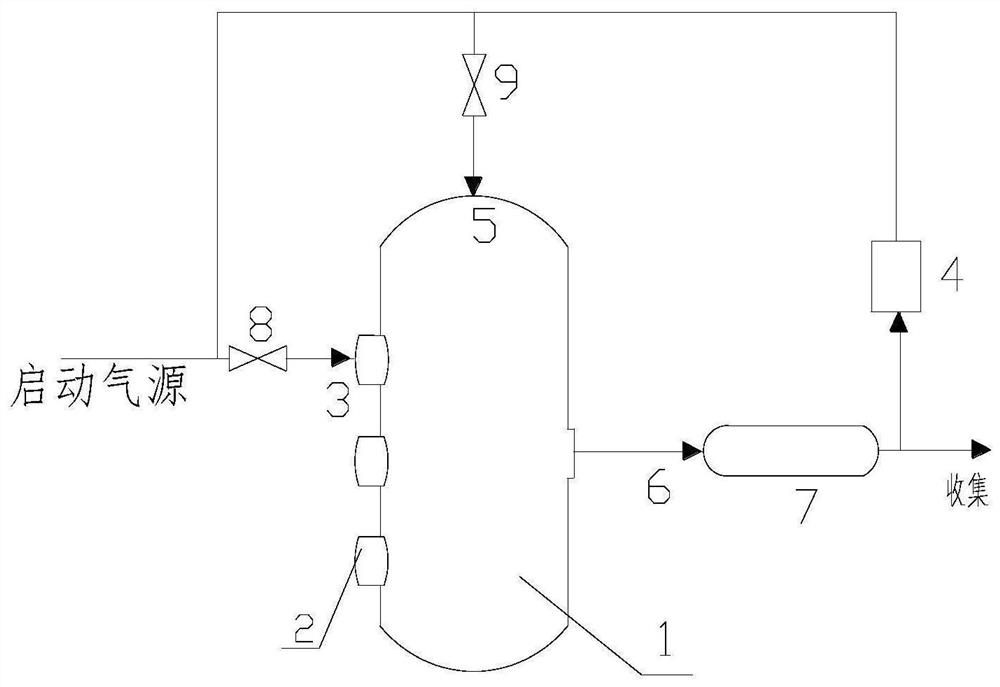

[0033] see figure 2 , The present embodiment provides a plasma hot blast stove and an industrial kiln 7 based on a plasma hot blast stove gas circulation recovery device, and an industrial kiln 7 in which the hot blast gas outlet 6 is connected.

[0034] In this embodiment, the plasma-based hot blast stove gas circulation recovery device also includes a cooling and purification device 4; the industrial kiln 7 is connected to the temperature-adjusting gas source inlet 5 and the starting gas source inlet 3 through the cooling and purification device 4, respectively. A control regulating valve 8 is also arranged between the cooling and purification device 4 and the starting air source inlet 3 . A second control regulating valve 9 is also provided between the cooling and purifying device 4 and the temperature regulating air source inlet 5 .

[0035] In this embodiment, the hot blast gas formed after the action of the plasma generator 2 is discharged from the furnace body 1 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com