High-precision aluminum frame wood formwork construction method

A construction method and technology of wood formwork, which are applied in building structures, formwork/formwork components, formwork/formwork/work frame connectors, etc., can solve the problem that the construction process of aluminum frame wood formwork has not yet formed a reliable research and summary , the lack of high-quality aluminum ore resources and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

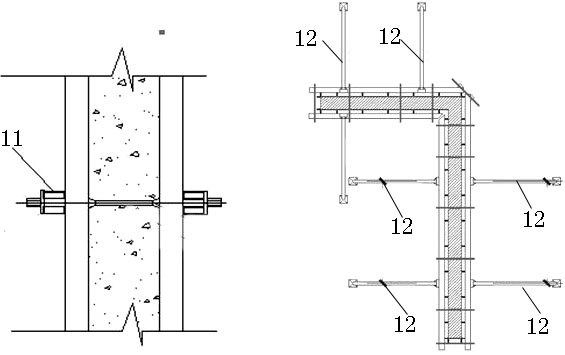

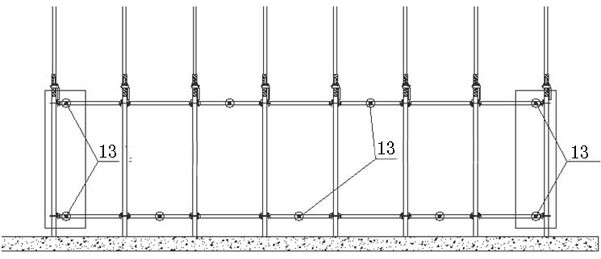

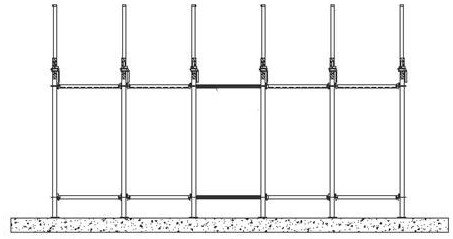

[0093] Such as Figure 1-7 Shown: a high-precision aluminum frame wood formwork construction method, which includes the following steps:

[0094] Step 1: Technical preparation:

[0095] 1) Technical and production personnel are familiar with the drawings, earnestly study and master the content, requirements and characteristics of the construction drawings, and at the same time make records for the doubts about the construction technology of the aluminum frame wood formwork and the drawings. The design of the aluminum formwork will be resolved through joint consultation. After reaching a consensus, the joint review record of the drawings will be processed as the basis for the change of the construction drawing and the basis for construction operations. According to the design requirements, the manufacturer is required to carry out the parameter design of the aluminum frame wood formwork. After the construction unit and the design confirmation , place an order immediately;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com