Community snow removal truck

A snowplow and community technology, applied in snow cleaning, construction, cleaning methods, etc., can solve the problems of high labor intensity of manual cleaning, inability to clear snow, and affecting the rest of community owners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

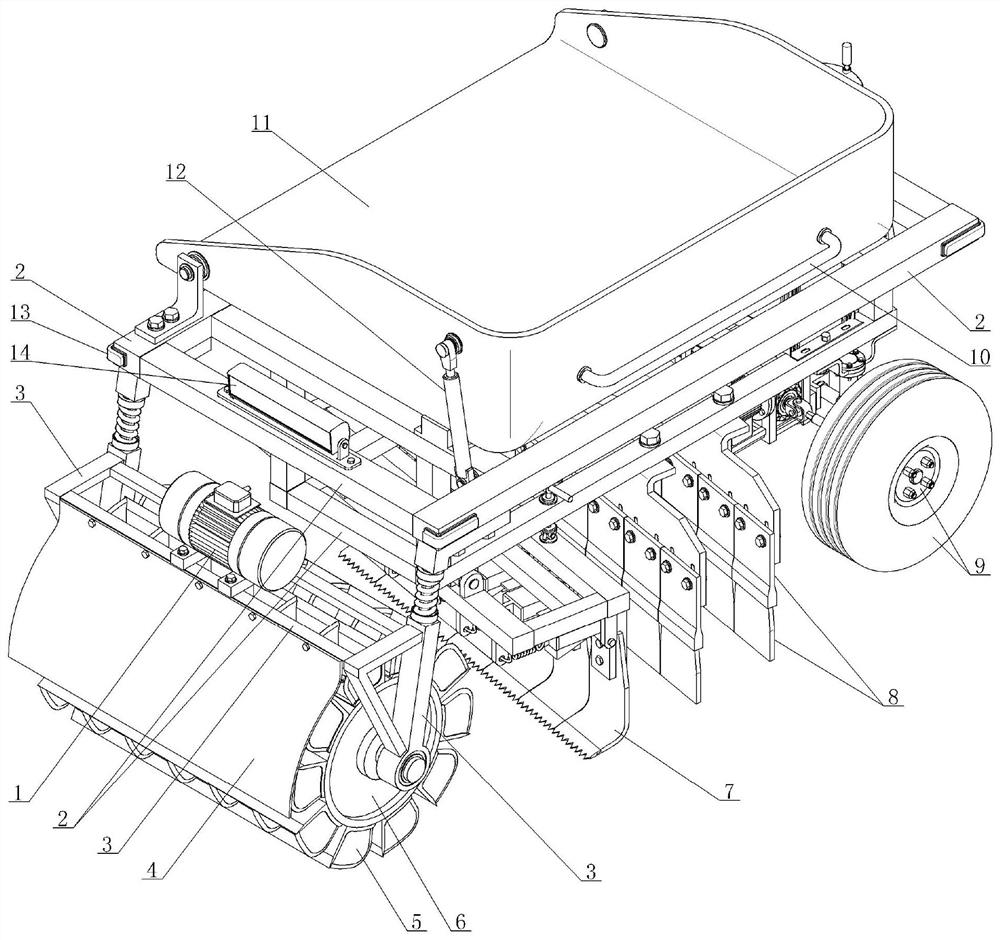

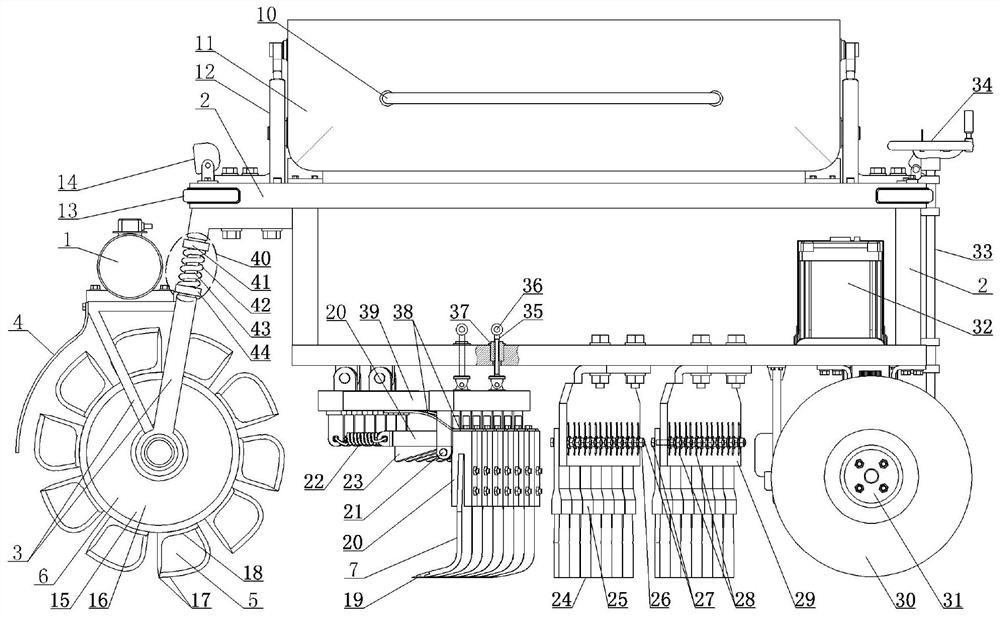

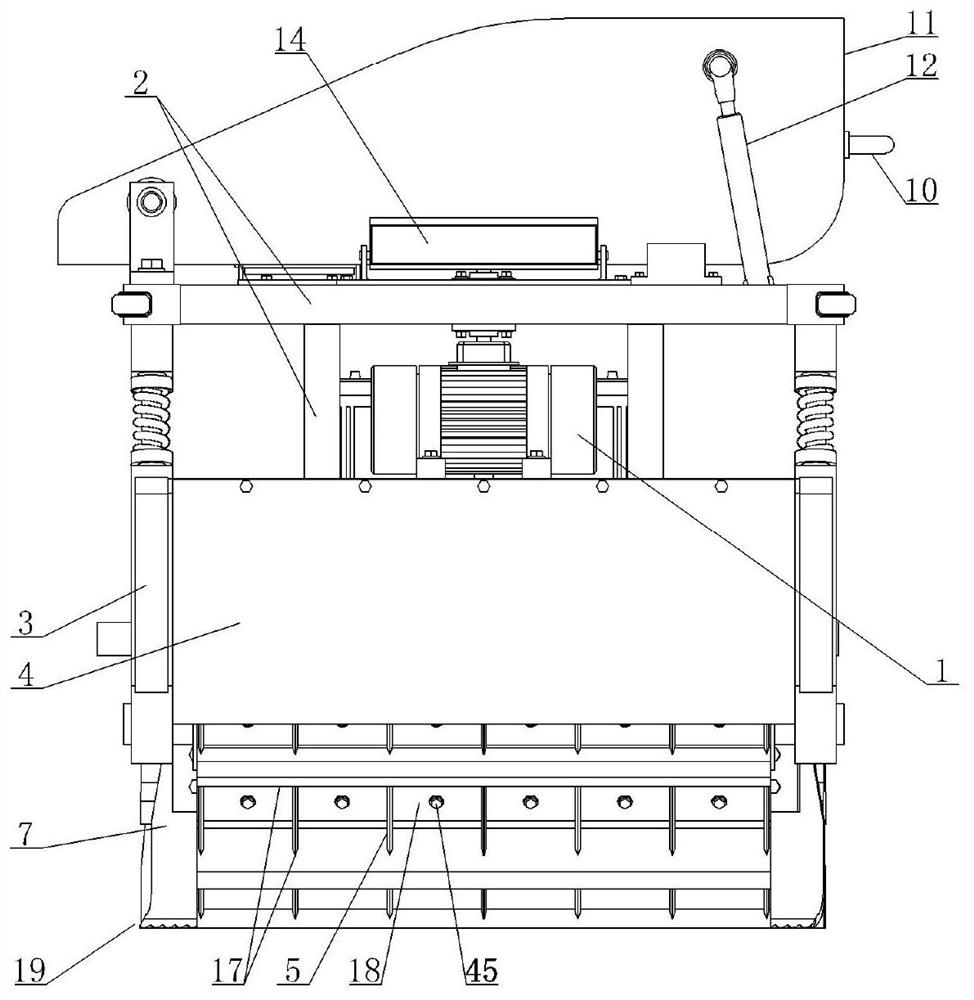

[0034] Community snowplows, such as Figure 1 to Figure 6 As shown, it comprises vehicle frame 2, and the front end of vehicle frame is equipped with roller frame 3, and the roller wheel 6 that rotatably connects is housed on the roller frame, and the outer circular surface of roller wheel is all over fixedly equipped with a plurality of snow cutting knives 5, each The blade 17 of the snow cutter or the arrangement of each snow cutter is L-shaped or T-shaped, and the rear end of the vehicle frame is equipped with a steering drive wheel 9, and between the steering drive wheel and the snow-cutting wheel, a snow brush 8 and a pair of snow brushes are arranged successively. Shaped snow shovel 7, the snow shovel and the snow sweeping brush are horizontally inclined and are contained in the lower end of the vehicle frame.

[0035] The snow sweeping brush comprises a brush plate 25 and a brush frame 29, and the lower end of the brush plate is provided with bristles 24, and the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com