A kind of moisture-absorbing breathable textile fabric and its production process

A technology of textile fabrics and production processes, applied in the field of clothing fabrics, can solve problems such as poor moisture absorption and air permeability, increased stuffiness, and clothing adhesion, and achieve strong moisture absorption and air permeability, good antibacterial performance, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

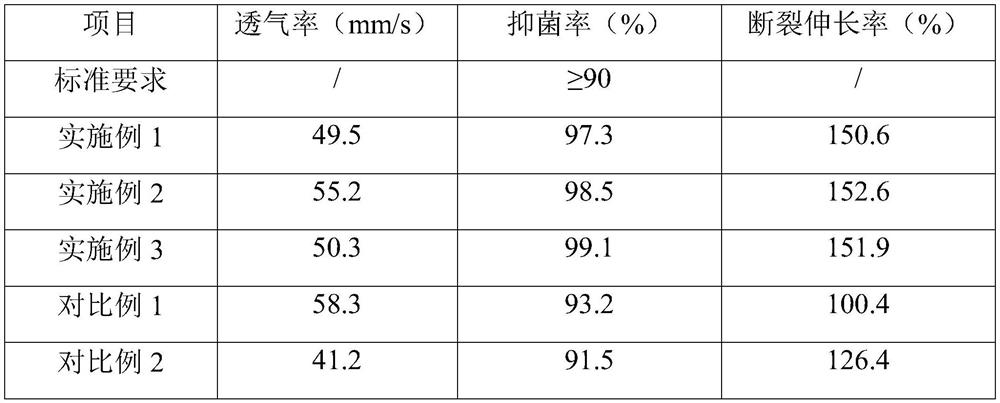

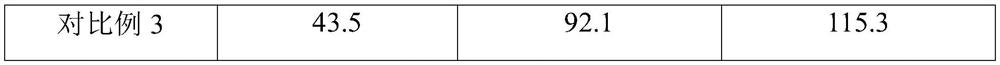

Examples

preparation example 1

[0071] a. First roving preparation

[0072] a1. the first colored antibacterial nylon fiber and the PVA fiber that the weight ratio is 50:50 are carried out the pre-opening process in the opener, then add the first colored antibacterial nylon fiber and the total amount of PVA fiber in the wool machine 1.5% blending oil, mixed evenly with the first colored antibacterial nylon fiber and PVA fiber, blended twice, and left to stand for 8 hours to obtain the raw material after blending;

[0073] a2. The raw material after kneading is opened by a cotton opener, carded by a carding machine, drawn by a drawing frame, and finally made into a roving by a roving machine to obtain the first roving;

[0074] b. Second roving preparation

[0075] After mixing the second colored antibacterial nylon fiber and tencel fiber with a weight ratio of 30:70, through the blowing carding unit, the second drawing frame of the drawing frame, and finally making roving through the roving frame to obtain ...

preparation example 2

[0079] a. First roving preparation

[0080] a1. the first colored antibacterial nylon fiber and PVA fiber that are 57.5:42.5 by weight ratio are carried out the pre-opening process in the opener, then add the first colored antibacterial nylon fiber and PVA fiber total amount in the wool machine 3. 25% blended crude oil, mixed with the first colored antibacterial nylon fiber and PVA fiber, blended 3 times, and left to stand for 10 hours to obtain the raw material after blending;

[0081] a2. The raw material after kneading is opened by a cotton opener, carded by a carding machine, drawn by a drawing frame, and finally made into a roving by a roving machine to obtain the first roving;

[0082] b. Second roving preparation

[0083] After mixing the second colored antibacterial nylon fiber and tencel fiber with a weight ratio of 50:50, through the blowing carding unit, the second drawing frame of the drawing frame, and finally making roving through the roving frame to obtain the ...

preparation example 3

[0087] a. First roving preparation

[0088] a1. the first colored antibacterial nylon fiber and the PVA fiber that the weight ratio is 65:35 are carried out the pre-opening process in the opener, then add the first colored antibacterial nylon fiber and the total amount of PVA fiber in the wool machine 5% wool oil, and mixed evenly with the first colored antibacterial nylon fiber and PVA fiber, wool 2 times, let stand for 12 hours, and obtain the raw material after wool;

[0089] a2. The raw material after kneading is opened by a cotton opener, carded by a carding machine, drawn by a drawing frame, and finally made into a roving by a roving machine to obtain the first roving;

[0090] b. Second roving preparation

[0091] After mixing the second colored antibacterial nylon fiber and tencel fiber with a weight ratio of 70:30, through the blowing carding joint, the second drawing frame of the drawing frame, and finally making roving through the roving frame to obtain the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com