High-altitude large-span supporting platform and construction method thereof

A technology for supporting platforms and large spans, which is applied in the direction of housing structure support, housing structure support, and scaffolding supported by housing structure, etc., can solve the problem that the wall thickness of steel pipes does not meet the requirements of the specification, the distance between vertical poles and steps are encrypted, and the construction period for erecting the frame body can be solved. Long and other problems, to achieve the effect of simple and convenient construction method, simple construction and assembly, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

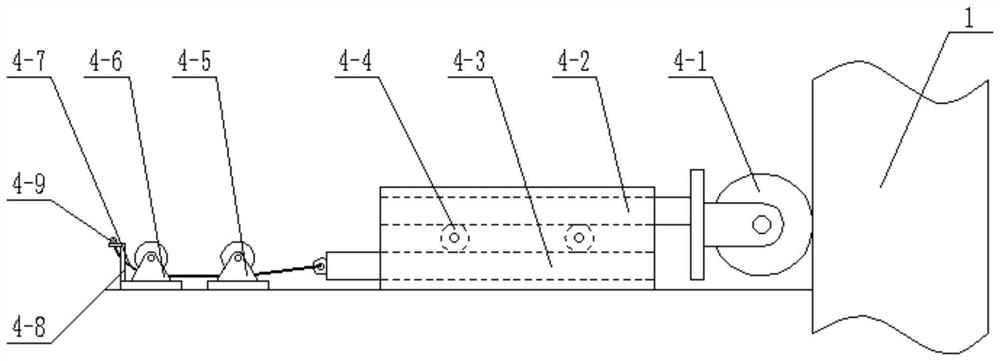

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, so that those skilled in the art can better understand the present invention and can be implemented, but the embodiment given is not as the limitation of the present invention, in the case of no conflict Next, the embodiments of the present invention and the technical features in the embodiments can be combined with each other.

[0034] It should be understood that in the description of the embodiments of the present invention, words such as "first" and "second" are only used to distinguish the purpose of description, and cannot be understood as indicating or implying relative importance, nor can they be understood as indicating or imply order. "Multiple" in the embodiments of the present invention refers to two or more.

[0035] The term "and / or" in the embodiment of the present invention is only an association relationship describing associated obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com