An automatic coal mine roadway coal transportation system

A technology of coal mine roadway and control system, which is applied in the directions of underground transportation, transportation and packaging, mechanical conveyor, etc., can solve the problems of high labor intensity, high risk coefficient, and unsatisfactory coal seam occurrence conditions for coal mining workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

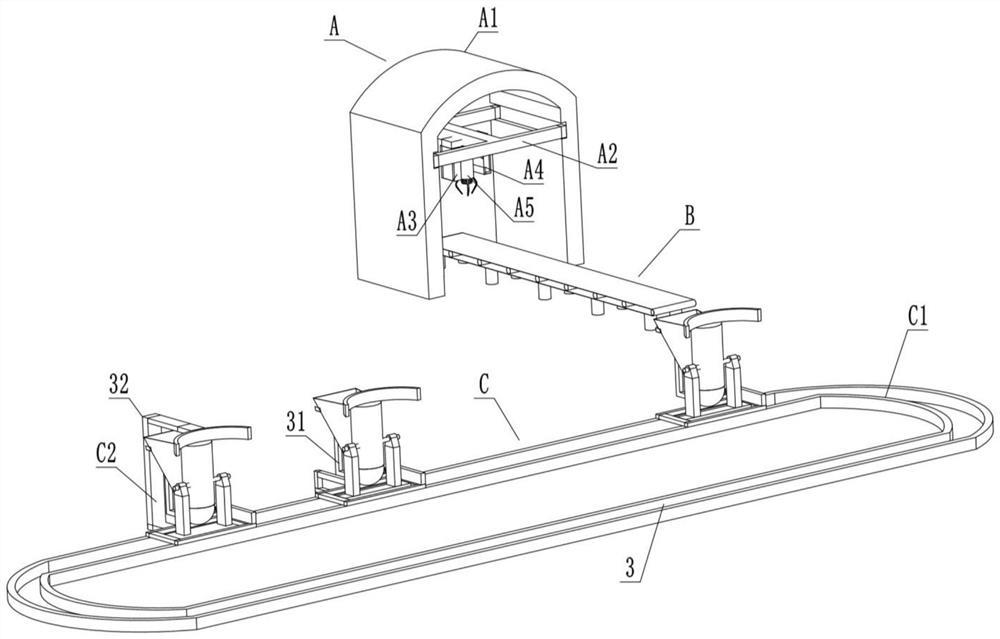

[0037] Such as figure 1 , figure 2 and image 3 As shown, an automatic coal transportation system mainly includes a coal grabbing mechanism, a conveyor belt system B, and a transfer system C arranged in the coal mine roadway 1 from the inside to the outside. The two sides slidingly connected in the slideway 11 of the coal mine roadway 1, and can slide according to the excavation depth of the coal mine roadway 1. The conveyor belt mechanism is arranged in the coal mine roadway 1 and is located under the coal grabbing mechanism. The outer side of the conveyor belt system is used to transfer the coal output from the end of the B end of the conveyor belt system. During the continuous excavation of the tunnel, the depth of the tunnel can be adapted by splicing the conveyor belt. Wherein the conveyor belt system B is a prior art, and will not be described too much in this embodiment, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com