Preparation method of anti-microorganism baby paper diaper

An integrated technology of baby diapers, applied in the field of hygiene products, can solve the problems of poor air permeability and poor antibacterial effect, and achieve the effects of avoiding low mechanical strength, keeping dryness, and increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

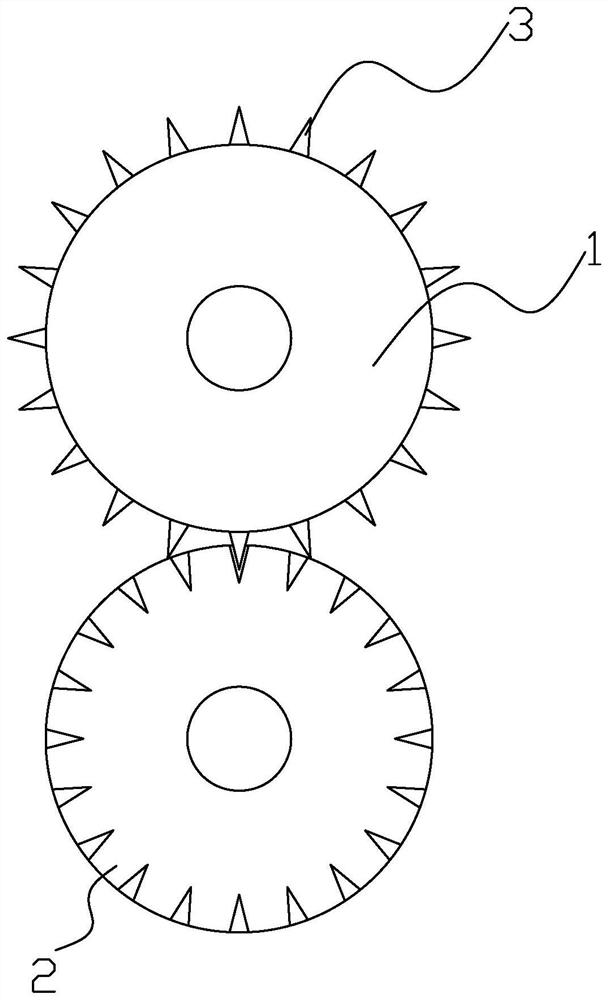

[0034] refer to figure 1 and figure 2 , a preparation method of antibacterial baby diapers, comprising the following preparation steps:

[0035] a: Prepare an antibacterial and breathable composite layer;

[0036] a1: Preparation of non-woven antibacterial surface layer: mix polypropylene slices and silver-loaded antibacterial masterbatches, send them to a granulator for granulation, and obtain spinning masterbatches, and then send spinning masterbatches to a screw extruder for melting For extruding, the heating temperature of the screw extruder is 70-290°C, and the temperature rises gradually from the feed end to the discharge end of the screw extruder. After being metered by a metering pump, it is sprayed, cooled, oiled, and shaped. , to obtain modified polypropylene fibers, and then send the modified polypropylene fibers into an opener to open and card to form a fiber web, and then reinforce them by acupuncture to obtain an antibacterial surface layer non-woven fabric; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com