Corn straw packaging device and corn straw comprehensive treatment method

A technology for comprehensive treatment of corn stalks, applied in packaging, application, agricultural machinery and equipment, etc., can solve the problems of inconvenient feeding, inconvenient reclaiming, slow manual packaging, etc., and achieve the effect of small recovery force and easy unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

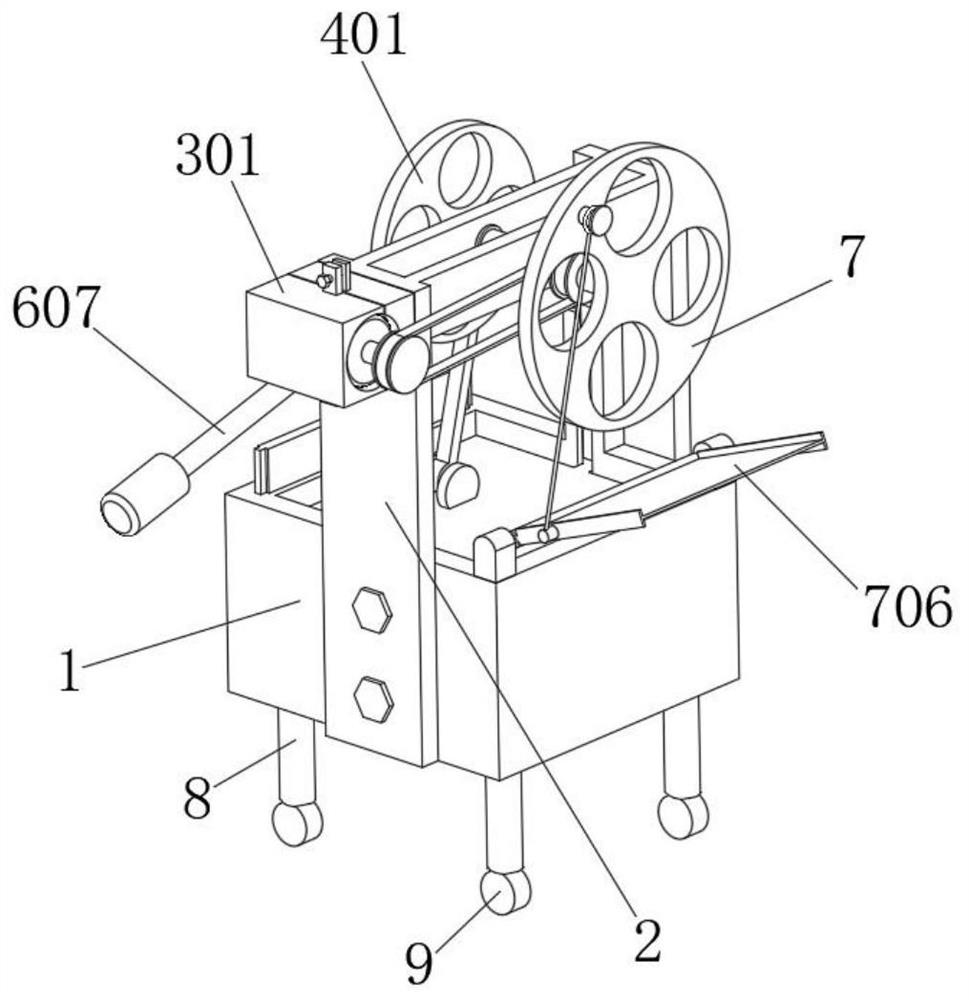

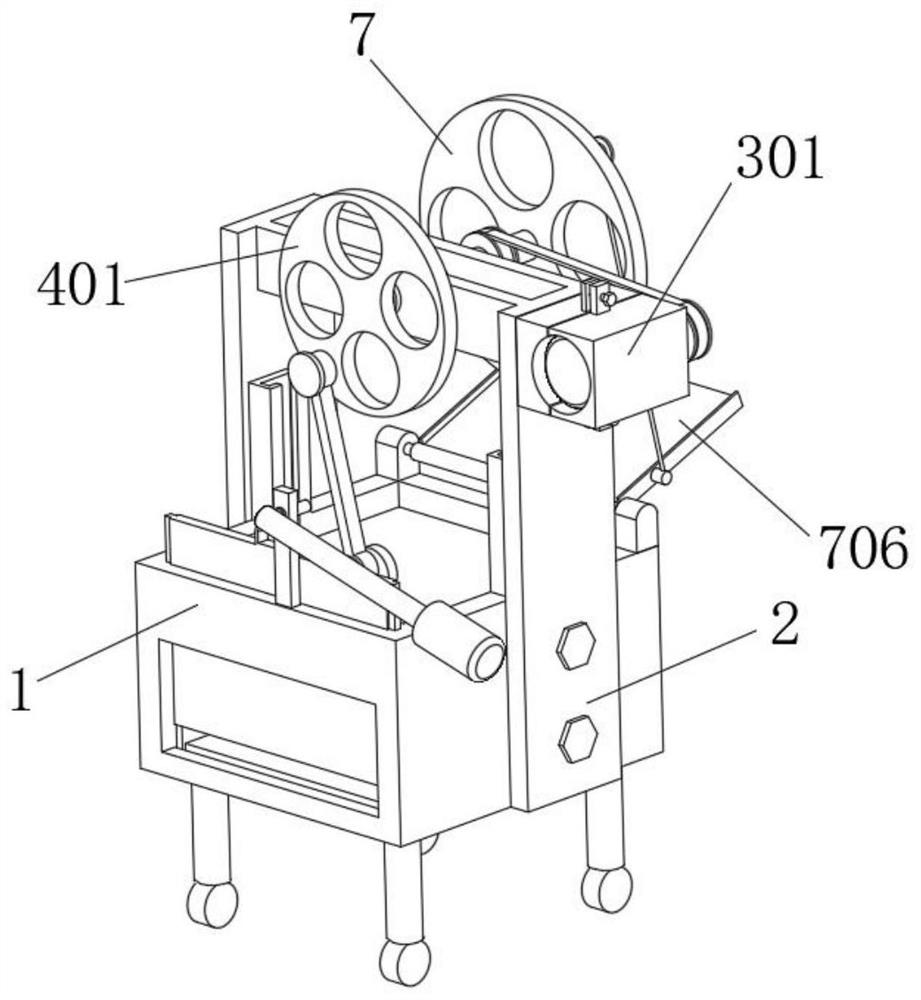

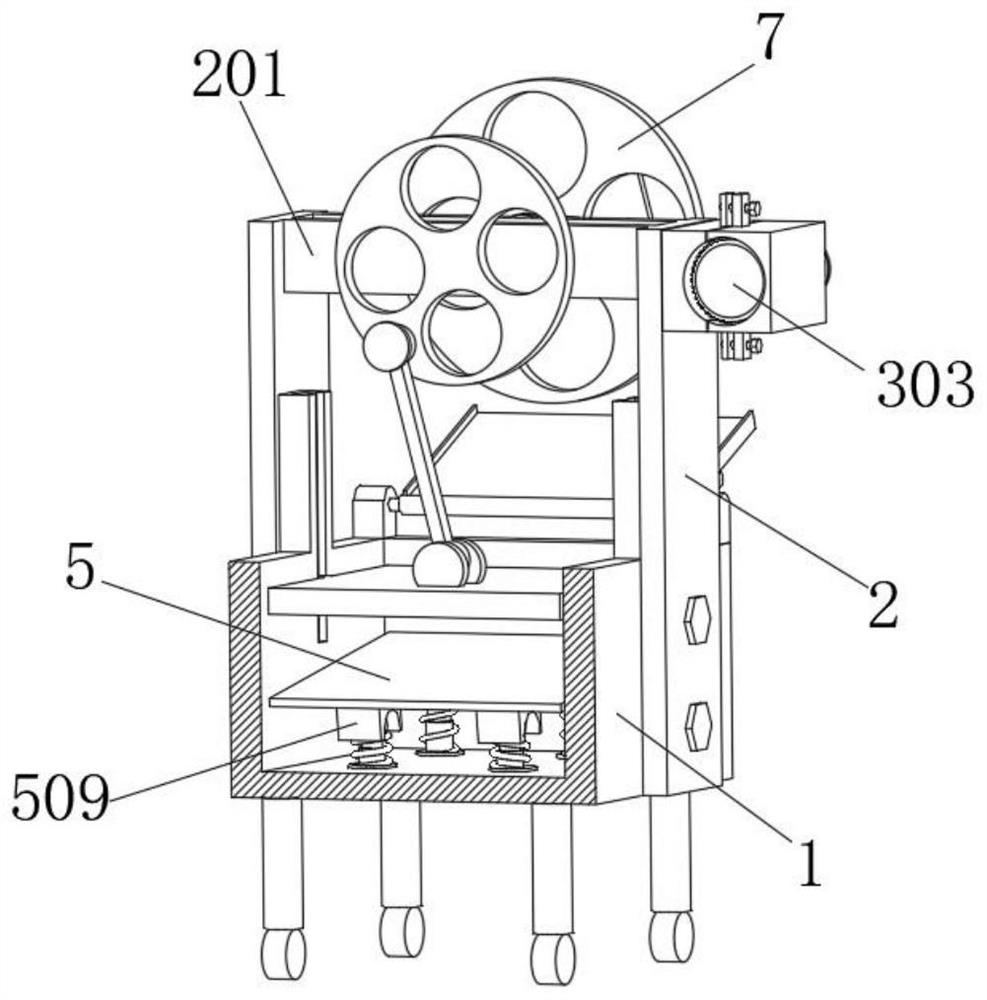

[0039] In a typical implementation of the present application, such as Figure 1-12As shown, a kind of corn stalk packing device equipment comprises packing box 1, and the top of described packing box 1 is fixedly connected with connecting rod 101, and one side of connecting rod 101 is provided with T-shaped chute 102, and packing box 1 There is a pressing plate 103, one side of the pressing plate 103 is fixedly connected with a T-shaped block 104, the T-shaped block 104 is adapted to the T-shaped chute 102, the top of the pressing plate 103 is fixedly connected with an arc-shaped block 105, and the arc-shaped block 105 is internally fixed Connected with a lifting shaft 106, one side of the packing box 1 is fixedly connected with a support plate 2, and the sides of the support plates 2 close to each other are fixedly connected with a first connecting plate 201 and a second connecting plate 202, one side of the supporting plate 2 Fixedly connected with an upper base 3, one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com