Manufacturing method of laminated lithium ion battery

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of manufacturing laminated lithium-ion batteries, can solve the problems of increasing power consumption of lithium-ion power batteries, high maintenance costs of lithium-ion power batteries, unfavorable heat dissipation, etc., and slow down the aging speed , the service life and the use effect are improved, and the effect of increasing the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

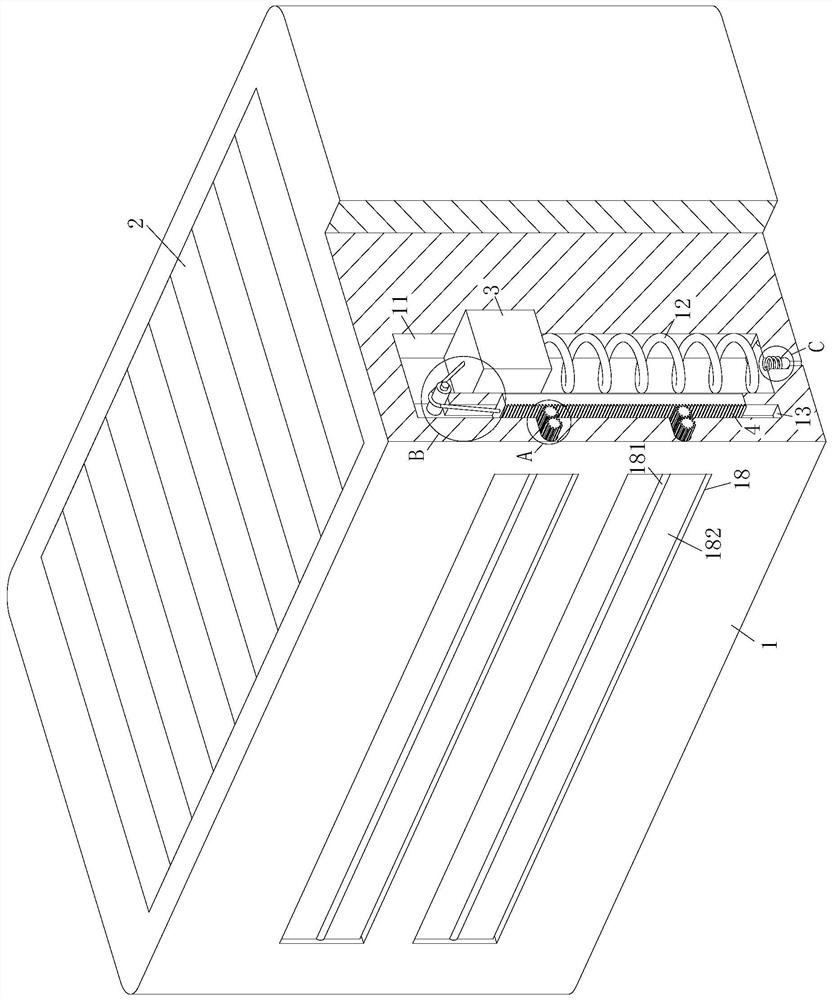

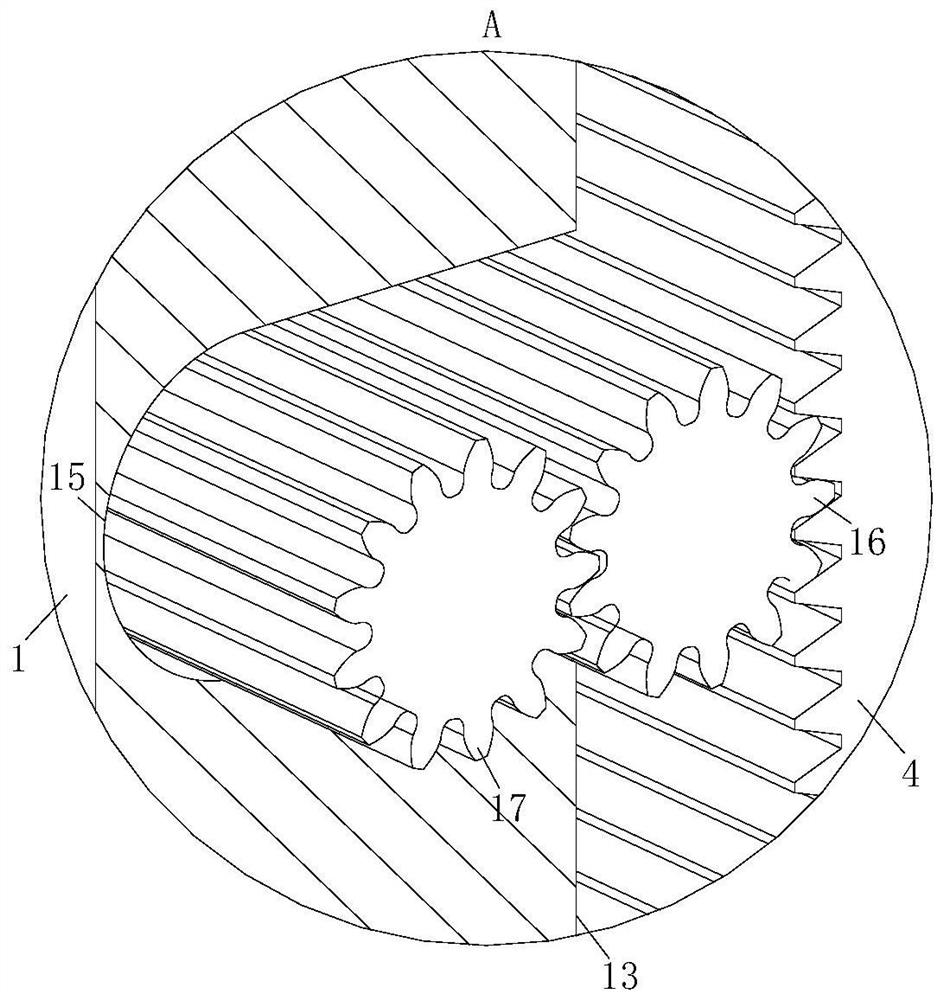

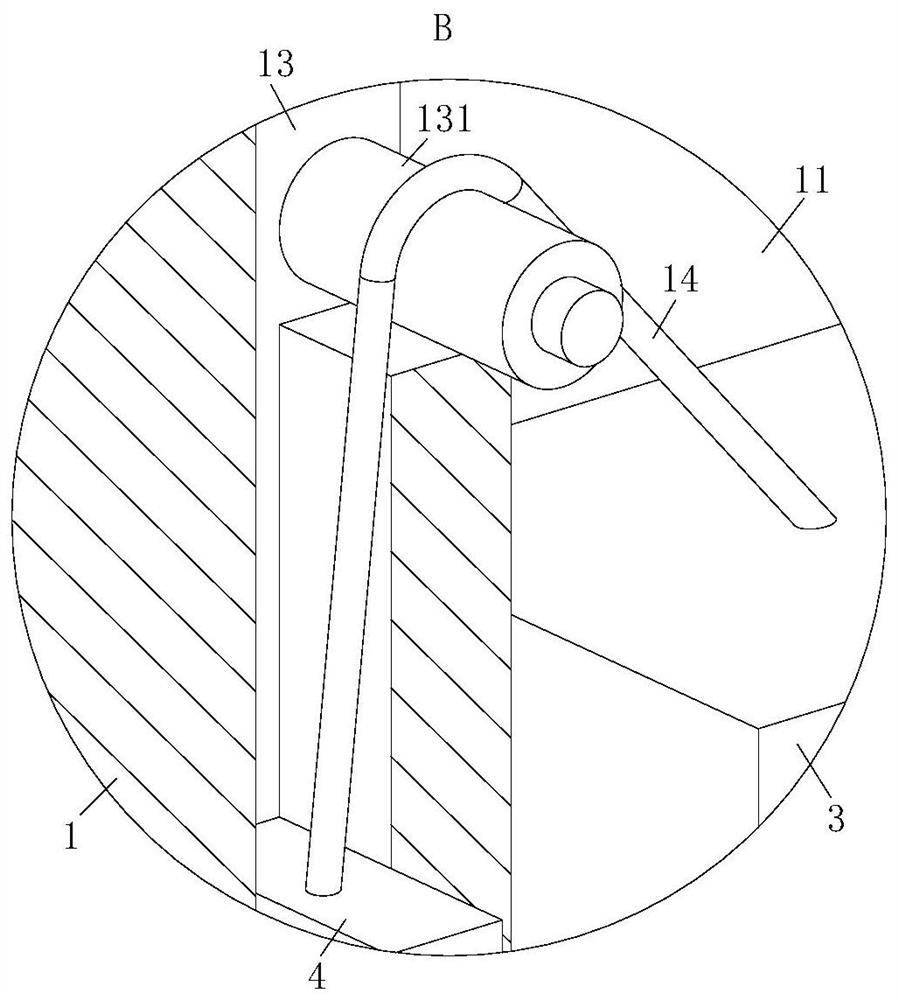

[0039] As an embodiment of the present invention, a ball 191 and a No. 2 spring 192 are arranged in the step hole 19; the ball 191 is located below the No. 2 spring 192; one end of the No. 2 spring 192 is connected to the step The inner wall of the hole 19 is connected to the ball 191 at the other end; the ball 191 blocks the step hole 19 under the action of the No. 2 spring 192; the inside of one end of the battery box 1 is provided with an L-shaped hole 5; One end of the L-shaped hole 5 is connected to the chute 11, and the other end is connected to the side wall of the ventilation groove 18; during operation, when the power block 3 slides upward along the chute 11, the power block 3 will drive the external airflow to overcome the second spring 192 Push the ball 191 away to open the external air flow, and when the power block 3 slides down along the slider, the stepped hole 19 is blocked by the action of the ball 191, so that the air pressure in the chute 11 is in the power b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com