Method for estimating rock-soil thermophysical parameters of sleeve type buried pipe

A technology of thermophysical parameters and buried pipes, which is applied in calculation, material thermal development, electrical digital data processing, etc., can solve the problem of low precision of geotechnical parameters, large deviation between calculation results and reference values, and no distinction correlation Differences and other issues, to achieve the effect of shortening the thermal response test time, reducing the thermal response test data, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

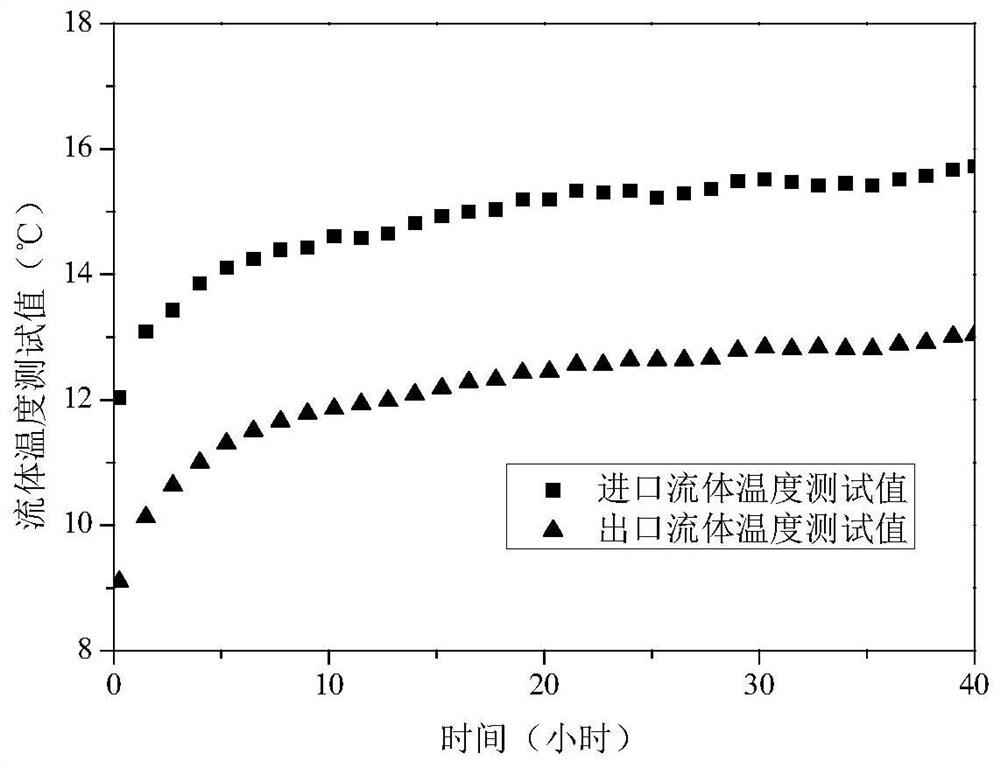

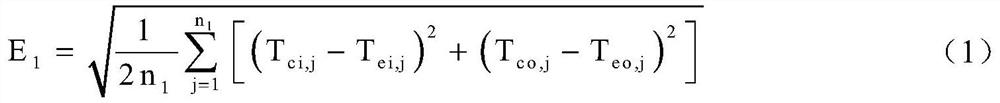

[0047] A method for estimating geotechnical parameters of casing-type buried pipes in this embodiment relies on the KTH Royal Institute of Technology The thermal response test of the casing-type buried pipe was completed, and the geotechnical parameters of the casing-type buried pipe were estimated based on the experimental data 20 hours before the thermal response test. Because the experimental data comes from previous literature, there are few experimental data available, such as figure 2 As shown, among them, the first test moment is 0.25 hours, and the interval between subsequent adjacent test moments is 1.25 hours. This embodiment only considers the experimental data of 20 hours before the thermal response test, therefore, the total number n of all test moments in the thermal response test 1 =17, and the total number n of the pre-test time (taking the first 10 hours) 2 =9.

[0048] The steps of the method for estimating the thermophysical property parameters of the c...

Embodiment 2

[0070] A method for estimating geotechnical parameters of a casing-type buried pipe in this embodiment is basically the same as in Embodiment 1, the difference is that this embodiment estimates the casing based on the experimental data 30 hours before the thermal response test Type buried pipe geotechnical thermal physical property parameters, therefore, the total number of test times n of the thermal response test in this embodiment 1 =25, and the total number n of the pre-test time (taking the first 10 hours) 2 =9. The steps of estimating geotechnical parameters in this embodiment are completely the same as those in Embodiment 1, and will not be repeated here.

[0071] The estimated results based on the experimental data 30 hours before the thermal response test are shown in Table 2. It can be seen from Table 2 that the relative error of the rock-soil thermal conductivity and volumetric specific heat capacity estimated in this embodiment is small and the accuracy is high. ...

Embodiment 3

[0075] A method for estimating geotechnical parameters of casing-type buried pipes in this embodiment is basically the same as in Embodiment 1, the difference is that this embodiment estimates the casing based on the experimental data 40 hours before the thermal response test Type buried pipe geotechnical thermal physical property parameters, therefore, the total number of test times n of the thermal response test in this embodiment 1 =33, and the total number n of the pre-test time (taking the first 10 hours) 2 =9. The steps of estimating geotechnical parameters in this embodiment are completely the same as those in Embodiment 1, and will not be repeated here.

[0076] Table 3 The geotechnical parameters and their errors estimated by the method of Example 3 and other methods (for the first 40 hours)

[0077]

[0078] The estimated results based on the experimental data of 40 hours before the thermal response test are shown in Table 3. It can be seen from Table 3 that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com